Abstract

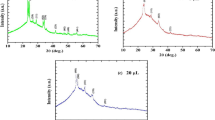

Using the template sol-gel method and employing polyethyleneimine, polyethylene glycol monooleate, and octylamine as templates, we obtain hybrid materials based on titanium dioxide whose structure contains ordered mesophases of organic substrates. The materials are studied using the thermal, X-ray phase, and X-ray diffraction analyses, as well as small-angle X-ray scattering. Films on a glass surface are obtained from isopropanol solutions containing titanium isopropoxide and organic templates via immersion technique. The surface structure of the films formed before and after annealing was studied by scanning probe microscopy. It is shown that, by using various structure-forming agents, it is possible to control the structure of hybrid materials and films in meso- and macroregions and to obtain titanium dioxide with different composition crystalline modifications during their heat treatment.

Similar content being viewed by others

References

Zhao, D., Feng, J., Huo, Q., et al., Science, 1998, vol. 279, p. 548.

Yang, P., Zhao, D., Margolese, D.I., et al., Nature, 1998, vol. 396, p. 152.

Zhang, Z., Wang, C., Zakaria, R., and Ying, J.Y., J. Phys. Chem., 1998, vol. 102, p. 10871.

Frindell, K.L., Bartl, M.H., Popitsch, A., and Stucky, G.D., Angew. Chem., 2002, vol. 41, p. 959.

Grosso, D., Crepaldi, E.L., Cagnol, F., et al., J. Chem. Mater, 2003, vol. 1, p. 4562.

Vinogradov, A.V. and Agafonov, A.V., Mendeleev Commun., 2009, vol. 19, p. 340.

Vinogradov, V.V., Agafonov, A.V., and Vinogradov, A.V., J. Sol-Gel Sci. Technol., 2009. V. 53. p. 312.

Vinogradov, V.V., Agafonov, A.V., and Vinogradov, A.V., Mendeleev Commun., 2009, vol. 19, no. 4, p. 222.

Sberveglieri, G., Depero, L.E., Ferroni, M., et al., Adv. Mater., 1996, vol. 8, p. 334.

Shi, J., Zheng, J., Hu, Y., and Zhao, Yu., Kinet. Katal., 2008, vol. 49, no. 2, p. 293 [Kinet. Catal. (Engl. Transl.), vol. 49, no. 2, p. 279].

Djaoued, Y., Badilescu, S., Taj, R., et al., Energy Technol., 2000, vol. 15, p. 657.

Vinogradov, À. and Agafonov, A., J. Sol-Gel Sci. Technol., 2009, vol. 49, p. 180.

Kormann, C., Bahnemann, D.W., and Hofmann, M.R., J. Phys. Chem., 1988, vol. 18, p. 5196.

Agafonov, A.V. and Vinogradov, A.V., Khim. Vys. Energ., 2008, vol. 42, no. 4, p. 79.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © A.V. Vinogradov, A.V. Agafonov, V.V. Vinogradov, 2010, published in Fizikokhimiya Poverkhnosti i Zashchita Materialov, 2010, Vol. 46, No. 5, pp. 483–486.

Rights and permissions

About this article

Cite this article

Vinogradov, A.V., Agafonov, A.V. & Vinogradov, V.V. Study of surfaces of TiO2-based nanostructured films obtained under action of various templates. Prot Met Phys Chem Surf 46, 555–558 (2010). https://doi.org/10.1134/S2070205110050096

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2070205110050096