Abstract

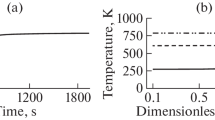

The process of dehydrating ethanol to ethylene by varying geometrical dimensions of a ring-shaped alumina catalyst is studied using a mathematical 2D model of a multitubular reactor. The set of ring sizes determines equivalent grain size Req, on which catalyst’s effectiveness factor η depends in turn. A procedure is proposed for assigning grains with different geometric dimensions to four structural groups, depending on the technique used to synthesize samples with the same equivalent size Req. Based on this approach, a system of criteria is developed for selecting catalyst grains with the best characteristics for given conditions. The geometric sizes of grains and other parameters that ensure the highest ethylene yield at the lowest values of the pressure drop and the residence time are determined.

Similar content being viewed by others

REFERENCES

Vernikovskaya, N.V., Chem. Eng. J., 2017, vol. 329, pp. 15–24.

Chumachenko, V.A., Ovchinnikova, E.V., Gribovskii, A.G., and Makarshin, L.L., Catal. Ind., 2016, vol. 8, no. 3, pp. 199–204. https://doi.org/10.1134/S2070050416030028

Ivanchina, E.D., Ivashkina, E.N., Kozlov, I.A., Dolganova, I.O., and Platonov, V.V., Katal. Prom-sti, 2015, no. 1, pp. 55–63.

Ovchinnikova, E.V., Chumachenko, V.A., and Valui-skikh, N.N., Catal. Ind., 2013, vol. 5, no. 4, pp. 297–311. https://doi.org/10.1134/S2070050413040077

Beskov, V.S., Brushtein, E.A., Vanchurin, V.I., Golovnya, E.V., and Yashchenko, A.V., Catal. Ind., 2010, vol. 2, no. 3, pp. 266–269. https://doi.org/10.1134/S2070050410030104

Klenov, O.P., Khanaev, V.M., Borisova, E.S., Sviri-donov, A.A., and Noskov, A.S., Katal. Prom-sti, 2008, no. S1, pp. 38–46.

Kagyrmanova, A.P., Zolotarskii, I.A., Vernikovskaya, N.V., Smirnov, E.I., Kuz’min, V.A., and Chumakova, N.A., Theor. Found. Chem. Eng., 2006, vol. 40, no. 2, pp. 155–167.

Davletshin, R.S., Mustafina, S.A., Balaev, A.V., and Spivak, S.I., Katal. Prom-sti, 2005, no. 6, pp. 34–40.

Morschbaker, A., J. Macromol. Sci., Polym. Rev., 2009, vol. 49, no. 2, pp. 79–84.

Vil’danov, F.Sh., Latypova, F.N., Chanyshev, R.R., and Nikolaeva, S.V., Bashk. Khim. Zh., 2011, no. 3, pp. 132–135.

Reddy, M.M., Vivekanandhan, S., Misra, M., Bhatia, S.K., and Mohanty, A.K., Prog. Polym. Sci., 2013, vol. 38, nos. 10–11, pp. 1653–1689.

Yakovleva, I.S., Banzaraktsaeva, S.P., Ovchinnikova, E.V., Chumachenko, V.A., and Isupova, L.A., Catal. Ind., 2016, vol. 8, no. 2, pp. 152–167. https://doi.org/10.1134/S2070050416020148.

Skiba, E.A., Baibakova, O.V., Budaeva, V.V., Pavlov, I.N., Vasilishin, M.S., Makarova, E.I., Sakovich, G.V., Ovchin-nikova, E.V., Banzaraktsaeva, S.P., Vernikovskaya, N.V., and Chumachenko, V.A., Chem. Eng. J., 2017, vol. 329, pp. 178–186.

Kagyrmanova, A.P., Chumachenko, V.A., Korotkikh, V.N., Kashkin, V.N., and Noskov, A.S., Chem. Eng. J., 2011, vols. 176–177, pp. 188–194.

Banzaraktsaeva, S.P., Ovchinnikova, E.V., Isupova, L.A., and Chumachenko, V.A., Russ. J. Appl. Chem., 2017, vol. 90, no. 2, pp. 169–178.

RF Patent 2609263C1, 2017.

Ovchinnikova, E.V., Isupova, L.A., Danilova, I.G., Danilevich, V.V., and Chumachenko, V.A., Russ. J. Appl. Chem., 2016, vol. 89, no. 5, pp. 683–689.

Danilevich, V.V., Lakhmostov, V.S., Zakharov, V.P., Tanashev, Yu.Yu., Sokolov, D.N., Isupova, L.A., and Parmon, V.N., Katal. Prom-sti, 2016, no. 1, pp. 13–28.

Zolotarskii, I.A., Voennov, L.I., Zudilina, L.Yu., Isupova, L.A., Zotov, R.A., Medvedev, D.A., Stepanov, D.A., Livanova, A.V., Meshcheryakov, E.P., and Kurzina, I.A., Catal. Ind., 2018, vol. 10, no. 1, pp. 49–56. https://doi.org/10.1134/S2070050418010129

Slin’ko, M.G., Dil’man, V.V., Markeev, B.M., and Kronberg, A.E., Khim. Prom-st’, 1980, no. 11, pp. 22–41.

Slin’ko, M.G., Modelirovanie khimicheskikh reaktorov (Modeling of Chemical Reactors), Novosibirsk: Nauka, 1968.

Malinovskaya, O.A., Beskov, V.S., and Slin’ko, M.G., Modelirovanie kataliticheskikh protsessov na poristykh zernakh (Modeling of Catalytic Processes on Porous Grains), Novosibirsk: Nauka, 1975.

Reid, R.C., Prausnitz, J.M., and Sherwood, T.K., The Properties of Gases and Liquids, New York: McGraw-Hill, 1977.

Kruglyakov, V.Yu., Isupova, L.A., Glazyrin, A.V., Danilevich, V.V., and Kharina, I.V., Katal. Prom-sti, 2016, no. 1, pp. 6–12.

ACKNOWLEDGMENTS

The authors are grateful to Dr. V.Y. Kruglyakov (BIC) for experimental testing mechanical strength of alumina catalysts and valuable suggestions on their implementation and Engineer S.S. Pogodkina (BIC) for assistance in computation.

This work was conducted within the framework of the budget project АААА-А17-117041710076-7 for the Boreskov Institute of Catalysis.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by E. Glushachenkova

Rights and permissions

About this article

Cite this article

Ovchinnikova, E.V., Banzaraktsaeva, S.P., Kalugina, E.A. et al. Mathematical Modeling of the Dehydrating Ethanol to Ethylene Process in a Multitubular Reactor on a Ring-Shaped Alumina Catalyst. Catal. Ind. 11, 80–86 (2019). https://doi.org/10.1134/S2070050419010082

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2070050419010082