Abstract

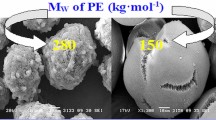

The effect of the particle size of an IK-8-21 domestic titanium-magnesium catalyst on the properties of polypropylene (PP) produced during the polymerization of propylene in a liquid monomer is studied. Catalysts with particle sizes of 20 to 64 μm are shown to have high activity and identical sensitivity to hydrogen and allow PP to be obtained with a narrow distribution of particles over size, high isotacticity, and close values of crystallinity, melting temperature, and physicomechanical properties. A slight decrease in the activity and bulk density of PP powder is observed when the average size of catalyst particles is increased from 20 to 43 μm. A more notable reduction in the activity and bulk density of PP powder is observed for catalyst with particle sizes of 62 to 64 μm. IK-8-21 catalyst is not inferior to its foreign analogues with respect to the properties of the resulting PP.

Similar content being viewed by others

References

Boor, J., Jr., Ziegler-Natta Catalysts and Polymerizations, New York: Academic Press, 1979.

Bukatov, G.D., Zaikovskii, V.I., Zakharov, V.A., Kryukova, G.N., Fenelonov, V.B., and Zagrafskaya, R.V., Vysokomol. Soedin., Ser. A, 1982, vol. 24, no. 3, pp. 542–548.

Polyolefins Planning Service (POPS) Report. Technology Review. New York: Nexant Inc., 2008.

Bukatov, G.D., Sergeev, S.A., Zakharov, V.A., Maier, E.A., Shabalin, E.Yu., and Ionov, A.R., Khim. Prom-st’, 2009, vol. 86, no. 6, pp. 293–296.

Dudchenko, V.K., Kolkov, K.M., and Maier, E.A., Plast. Massy, 2011, no. 10, pp. 45–49.

Salakhov, I.I., Batyrshin, A.Z., Sergeev, S.A., Bukatov, G.D., Barabanov, A.A., Sakhabutdinov, A.G., Zakharov, V.A., and Gilmano., Kh.Kh., Catal. Ind., 2014, vol. 6, no. 3, pp. 198–201.

RF Patent 2191196, 2002.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © I.I. Salakhov, A.Z. Batyrshin, S.A. Sergeev, G.D. Bukatov, A.A. Barabanov, M.A. Mats’ko, A.G. Sakhabutdinov, V.A. Zakharov, 2016, published in Kataliz v Promyshlennosti.

Rights and permissions

About this article

Cite this article

Salakhov, I.I., Batyrshin, A.Z., Sergeev, S.A. et al. Effect of titanium–magnesium catalyst morphology on the properties of polypropylene upon propylene polymerization in a liquid monomer. Catal. Ind. 8, 213–216 (2016). https://doi.org/10.1134/S2070050416030107

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2070050416030107