Abstract

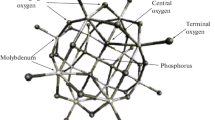

The homogeneous catalyst used in the 2005–2006 scale-up of the oxidation of n-butylenes into methylethylketone to the industrial level is a chloride-free aqueous solution of palladium complexes in a modified 0.25 M solution of Mo-V-P heteropoly acid with the molecular formula H12P3Mo18V7O85 (HPA-7′). Its advantages are increased oxidative capacity in the primary oxidation of n-C4H8 and increased thermal stability, which allows quick catalyst regeneration with atmospheric oxygen at 160–170°C. The paper describes the preparation of a pilot lot of the catalyst with a total volume of 50 L; the starting substances were V2O5, MoO3, and H3PO4. The key point of the synthesis was dissolving V2O5 while stirring in a dilute and cooled H2O2 solution. This formed V(V) peroxide complexes, which decompose at elevated temperature to give a 0.0175 M H6V10O28 solution. This solution was stabilized by adding a calculated amount of H3PO4 to give a more stable 0.0125 M H9PV14O42 solution. Since the H9PV14O42 solution occupied a large volume, its synthesis was performed three times in a 300-L reactor. In the main 500-L reactor, MoO3 was dissolved in water with stirring, while adding the remaining portion of H3PO4. The resulting mixture was evaporated, gradually introducing all of the previously obtained portions of the dilute H9PV14O42 solution. The resulting HPA-7′ solution was evaporated to ∼100 L and filtered twice, separating the insignificant amount of the precipitate. The filtered solution was again evaporated to 50 L, and a calculated amount of PdCl2 was added to it while stirring at 70–80°C. A total of 27 lots of the (Pd + 0.25 M HPA-7′) catalyst with a total volume of 1350 L were obtained. All apparatuses of the pilot industrial unit for MEK synthesis were filled with this catalyst.

Similar content being viewed by others

References

BE Patent 828603, 1975.

Smidt, J. and Krekeler, H., Hydrocarbon Process. Pet. Refin., 1963, vol. 42, no. 7, pp. 149–152.

Kozik, B.L., Pestrikov, S.V., and Savel’ev, A.P., Khim. Tekhnol. Topl. Masel, 1963, no. 11, pp. 11–15.

RF Patent 2230612, Izobreteniya, 2004, no. 17, part II, p. 389.

Zhizhina, E.G., Simonova, M.V., Odyakov, V.F., and Matveev, K.I., Appl. Catal., A, 2007, vol. 319, pp. 91–97.

Zhizhina, E.G., Odyakov, V.F., and Simonova, M.V., Kinet. Catal., 2008, vol. 49, no. 6, pp. 773–781.

Odyakov, V.F. and Matveev, K.I., Zh. Neorg. Khim., 1997, vol. 42, no. 5, pp. 718–720.

Odyakov, V.F., Zhizhina, E.G., Maksimovskaya, R.I., and Matveev, K.I., Zh. Neorg. Khim., 1998, vol. 43, no. 9, pp. 1451–1455.

Odyakov, V.F. and Matveev, K.I., USSR Inventor’s Certificate no. 1782934, Byull. Izobret., 1992, no. 33, p. 86.

Odyakov, V.F., Zhizhina, E.G., Maksimovskaya, R.I., and Matveev, K.I., Kinet. Katal., 1995, vol. 36, no. 5, pp. 795–800.

Novyi spravochnik khimika i tekhnologa. Osnovnye svoistva neorganicheskikh, organicheskikh i elementoorganicheskikh soedinenii (New Chemical Engineer’s Handbook: Basic Properties of Inorganic, Organic, and Elementoorganic Compounds), Skvortsov, N.K., Ed., St. Petersburg: NPO Mir i sem’ya, 2002.

Odyakov, V.F., Zhizhina, E.G., and Matveev, K.I., J. Mol. Catal. A: Chem., 2000, vol. 158, no. 1, pp. 453–456.

Standard Potentials in Aqueous Solution, Bard, R., Parsons, J., and Jordan, J., Eds., New York: Marcel Dekker, 1985.

Odyakov, V.F., Zhizhina, E.G., and Maksimovskaya, R.I., Appl. Catal., A, 2008, vol. 342, nos. 1–2, pp. 126–130.

Zhizhina, E.G. and Odyakov, V.F., React. Kinet. Catal. Lett., 2008, vol. 95, no. 2, pp. 301–312.

Zhizhina, E.G. and Odyakov, V.F., Appl. Catal., A, 2009, vol. 358, no. 2, pp. 254–258.

Matveev, K.I., Zhizhina, E.G., Odyakov, V.F., and Parmon, V.N., Catal. Ind., 2014, vol. 6, no. 3, pp. 202–211.

Howarth, O.W. and Hunt, J.R., J. Chem. Soc., Dalton Trans., 1979, no. 9, pp. 1388–1391.

Alonso, B. and Livage, J., J. Solid State Chem., 1999, vol. 148, no. 1, pp. 16–19.

Dean, G.A., Can. J. Chem., 1961, vol. 39, no. 6, pp. 1174–1183.

Jahr, K.F. and Preuss, F., Chem. Ber., 1965, vol. 98, no. 10, pp. 3297–3302.

Meyer, J., Z. Anorg. Allg. Chem., 1927, vol. 161, pp. 321–336.

Novyi spravochnik khimika i tekhnologa. Khimicheskoe ravnovesie. Svoistva rastvorov (New Chemical Engineer’s Handbook: Chemical Equilibrium and Properties of Solutions), St. Petersburg: NPO Professional, 2004.

Aoshima, A. and Yamaguchi, T., Nippon Kagaku Kaishi, 1987, no. 6. pp. 969–975.

FRG Patent 2722375, Chem. Abstr., 1978, vol. 88, no. 20, 142283k.

Maksimov, G.M., Molchanov, V.V., and Goidin, V.V., Khim. Prom-st., 1997, no. 7, pp. 507–509.

Molchanov, V.V., Maksimov, G.M., Maksimovskaya, R.I., Goidin, V.V., and Buyanov, R.A., Inorg. Mater., 2003, vol. 39, no. 7, pp. 687–693.

Fontenot, C.J., Wiench, J.W., Pruski, M., and Schrader, G.L., J. Phys. Chem. B, 2000, vol. 104, no. 49, pp. 11622–11631.

Odyakov, V.F. and Zhizhina, E.G., Russ. J. Inorg. Chem., 2009, vol. 54, no. 3, pp. 361–367.

Livage, J., Coord. Chem. Rev., 1998, vols. 178–180, part 2, pp. 999–1018.

Atlamsani, A., Ziyad, M., and Bregeault, J.M., J. Chim. Phys. Phys.-Chim. Biol., 1995, vol. 92, nos. 7–8, pp. 1344–1364.

Odyakov, V.F., Zhizhina, E.G., and Matveev, K.I., Katal. Prom-sti, 2007, no. 4, pp. 19–25.

Odyakov, V.F. and Zhizhina, E.G., Kinet. Catal., 2011, vol. 52, no. 6. pp. 828–834.

Zhizhina, E.G., Simonova, M.V., Odyakov, V.F., and Matveev, K.I., Katal. Prom-sti, 2005, no. 2, pp. 17–25.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © V.F. Odyakov, E.G. Zhizhina, K.I. Matveev, V.N. Parmon, 2015, published in Kataliz v Promyshlennosti.

Rights and permissions

About this article

Cite this article

Odyakov, V.F., Zhizhina, E.G., Matveev, K.I. et al. Homogeneous catalysts of redox reactions based on heteropoly acid solutions. II. Synthesis of catalyst for pilot industrial production of methylethylketone. Catal. Ind. 7, 111–118 (2015). https://doi.org/10.1134/S2070050415020087

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2070050415020087