Abstract

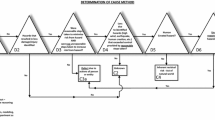

Analyzing the efficiency of preventive measures based on probability relations of reliability theory demonstrates that these measures principally rank below nondestructive testing (defectoscopy, or flaw detection), which represents a direct diagnostic method for preventing failures and accidents. The proposed mathematical model rests on the interpretation of nondestructive testing as observations of the current state of the basic reliability parameter, namely, the failure rate. Analytical relations of the model are obtained using Kolmogorov’s equations for the limiting probabilities of the state graph of an item–defectoscope system. The model has the following parameters: the failure and restoration rates of an item, the probabilities of errors of the first and second kind of the faults' detection, and the frequency of item testing. The results demonstrate the technological and economic efficiency of flaw detection. Here, the frequency of testing is more important for economic efficiency than small probabilities of errors. The model can be used to optimize performance specifications for the design of flaw detection equipment. The numerical examples approximately correspond to conditions of offshore industry.

Similar content being viewed by others

References

W. Feller, An Introduction to Probability Theory and Its Applications, 3rd ed. (Wiley, New York, Chichester, Brisbane, Toronto, 1970), Vols. 1, 2.

GOST (State Standard) No. 27.002-89: The Reliability of the Technique. Basic Concepts. Terms and Definitions.

A. M. Polovko and S. V. Gurov, Principles of Reliability Theory (BKhV-Peterburg, St. Petersburg, 2006) [in Russian].

A. L. Kurakin, “Prognostication of data-bases safety,” SOFTWARE & SYSTEMS, No. 2, 13–17 (1998). ISSN 0236-235X http://swsys.ru/index.php?page=article&id=980

N. P. Aleshin and V. G. Shcherbinskii, Radiation, Ultrasonic and Magnetic Particle Inspection of Fabricated Metal Products (Vyssh. Shkola, Moscow, 1991) [in Russian].

Ultrasonic Control, Ed. by V. A. Troitskii (Inst. Elektrosvarki im. E. O. Patona NAN Ukrainy, Kiev, 2006) [in Russian].

N. A. Rimskii-Korsakov and V. A. Sychev, “Trends in developments and applications of hydroacoustic media for detection, identification, research, and monitoring of underwater objects,” in Proceedings of the 9th ScientificPractical Conference on Forecasting of Emergencies, May 14–15, 2009 (Ministerstvo Chrezvych. Situatsii, Moscow, 2009), pp. 188–202.

E. L. Lehman, Testing Statistical Hypotheses (Wiley, Chapman Hall, New York, London, 1959).

A. L. Kurakin, “Bayes approach to hypotheses testing in monitoring problems,” General Intern. Services (F&B, New York, 2011), ID: 10230867. http://www.lulu.com/

A. L. Kurakin, “Algorithm for object detecting during continuous monitoring,” SOFTWARE & SYSTEMS, No. 3, 166–169 (2011).

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © A.L. Kurakin, L.I. Lobkovsky, 2015, published in Matematicheskoe Modelirovanie, 2015, Vol. 27, No. 6, pp. 99–111.

Rights and permissions

About this article

Cite this article

Kurakin, A.L., Lobkovsky, L.I. Mathematical model of flaw detection. Math Models Comput Simul 8, 84–91 (2016). https://doi.org/10.1134/S2070048216010063

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2070048216010063