Abstract

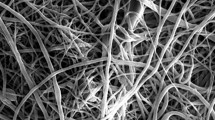

The application of nonwoven fibrous matrices made of biodegradable polymers for medicine and tissue engineering is a promising direction in bioengineering. The matrices based on poly-3-oxybutyrate biopolymer with the use of titanium dioxide and silicon nanoparticles have been produced via electrospinning. It is found that nanoscale particles accelerate crystallization and melting of polymer and improve the physicomechanical parameters of the fibrous materials. It has been shown that the most favorable foundation for growth of the living cells is matrices made of filaments of small diameter. Nonwoven fibrous matrices of poly-3-oxybutyrate can be proposed for tissue engineering and traumatology.

Similar content being viewed by others

REFERENCES

G. Meier Burgisser and J. Buschmann, “History and performance of implant materials applied as peritendinous antiadhesives,” J. Biomed. Mater. Res. B Appl. Biomater. 103 (1), 212–228 (2015).

P. D. Fabricant, K. J. Jones, D. Delos, F. A. Cordasco, R. G. Marx, A. D. Pearle, R. F. Warren, and D. W. Green, “Reconstruction of the anterior cruciate ligament in the skeletally immature athlete: A review of current concepts,” J. Bone Joint Surg. Am. 95-A (5), 1–13 (2013). http://dx.doi.org/https://doi.org/10.2106/JBJS.L.00772

K. Markatos, G. Tsoucalas, and M. Sgantzos, “Hallmarks in the history of orthopaedic implants for trauma and joint replacement,” Acta Med. Hist. Adriat. 14 (1), 161–176 (2016).

A. A. Ol’khov, O. V. Staroverova, M. A. Gol’dshtrakh, A. V. Khvatov, K. Z. Gumargalieva, and A. L. Iordanskii, “Electrospinning of biodegradable poly-3-hydroxybutyrate. Effect of the characteristics of the polymer solution,” Russ. J. Phys. Chem. B 10 (5), 830–838 (2016).

C. Kriegel, A. Arecchi, K. Kit, D. J. McClements, and J. Weiss, “Fabrication, functionalization, and application of electrospun biopolymer nanofibers,” Crit. Rev. Food Sci. Nutr. 48 (8), 775–797 (2008).

I. Vasilyeva, G. Kuz’micheva, A. Gainanova, O. Timaeva, A. Dorokhov, A. Pochtar, and V. Podbel’skiy, “On the nature of the phase η-TiO2,” New J. Chem. 40 (1), 151–161 (2016).

A. O. Rybaltovskiy, Y. S. Zavorotny, A. A. Ischenko, M. A. Lazov, A. V. Garshev, S. G. Dorofeev, N. N. Kononov, N. V. Minaev, S. A. Minaeva, A. P. Sviridov, P. S. Timashev, I. I. Khodos, V. I. Yusupov, V. Y. Panchenko, and V. N. Bagratashvili, “Synthesis of photoluminescent Si/SiO x core/shell nanoparticles by thermal disproportionation of SiO: Structural and spectral characterization,” J. Mater. Sci. 50 (5), 2247–2256 (2015).

Y. Filatov, A. Budyka, and V. Kirichenko, Electrospinning of Micro- and Nanofibers: Fundamentals in Separation and Filtration Processes (Begell House Inc, New York, 2007).

S. Wang, X. Qu, and R. C. Zhao, “Mesenchymal stem cells hold promise for regenerative medicine,” Front. Med. 5 (4), 372–378 (2011).

J. A. Kode, S. Mukherjee, M. V. Joglekar, and A. A. Hardikar, “Mesenchymal stem cells: Immunobiology and role in immunomodulation and tissue regeneration,” Cytotherapy 11 (4), 377–391 (2009).

X. J. Tang and Q. Y. Wu, “Mesenchymal stem cellular adhesion and cytotoxicity study of random biopolyester scaffolds for tissue engineering,” J. Mater. Sci.: Mater. Med. 17, 627–632 (2006).

A. A. Olkhov, O. V. Staroverova, A. P. Bonartsev, I. I. Zharkova, E. D. Sklyanchuk, A. L. Iordanskii, S. Z. Rogovina, A. A. Berlin, and A. A. Ishchenko, “Structure and properties of ultrathin poly-3-hydroxybutirate) fibers modified by silicon and titanium dioxide particles,” Polym. Sci., Ser. D 8 (2), 100–109 (2015).

A. A. Ol’khov, V. S. Akatov, A. A. Prosvirin, O. V. Staroverova, Yu. N. Filatov, M. A. Gol’dshtrakh, and A. L. Iordanskii, “Implants for reconstructive surgery based on electrospun poly(3-hydroxybutyrate) fibers,” Fibre Chem. 49 (3), 222–226 (2017).

ACKNOWLEDGMENTS

This work was partially supported by the Plekhanov Russian University of Economics (A.A. Ol’khov) and Russian Foundation for Basic Research (project no. 15-29-04862-ofi_m) (V.N. Gorshenev) and within the frameworks of a state order for the Institute of Chemical Physics, Russian Academy of Sciences (0082-2014—0009, state registration no. AAAA-A17-117040610309-0) (A.L. Iordanskii), and a state order for the Institute of Chemical Physics, Russian Academy of Sciences (0082-2018-0006, state registration no. AAAA-A18-118020890097-1 (O.V. Staroverova).

The measurements were carried out with the use of the New Materials and Technologies Center of Collective Use of the Institute of Biochemical Physics, Russian Academy of Sciences .

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by K. Aleksanyan

Rights and permissions

About this article

Cite this article

Ol’khov, A.A., Gorshenev, V.N., Staroverova, O.V. et al. The Morphology of Fibrous Matrices for Medical Use from Poly-3-Oxybutyrate Obtained by Electrospinning. Polym. Sci. Ser. D 12, 58–63 (2019). https://doi.org/10.1134/S1995421219010143

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1995421219010143