Abstract

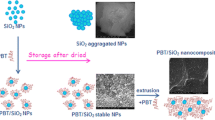

The possibility of implementing entropic mixing for preparing nanocomposites based on thermodynamically compatible components was studied in this work. Polylactide was used as matrix polymer; molecular silicasols with modified surface were employed as a filler. The shell hydrophile of these particles decreases interfacial tension and prevents their aggregation in the bulk of the nanocomposite. A preliminary assessment of the thermodynamic compatibility of polylactide with the selected type of molecular silicasols was performed. The structure of obtained composites was studied by small-angle X-ray scattering. The necessity of modifying the nanoparticle surface by groups compatible with the matrix polymer, which makes it possible to prepare a composite where all filler is dispersed within the matrix to the nanoscale level without using supplementary dispersion techniques, was shown in the work.

Similar content being viewed by others

References

Polymer Nanocomposites, Ed. by Yiu-Wing and Yu. Zhong-Zhen (Woodhead Publ., Boston, New York, Washington, 2006).

G. Cao and Y. Wang, Nanostructures and Nanomaterials. Synthesis, Properties and Applications (Word Sci., 2011).

B. D. Summ and N. I. Ivanova, “Fields and methods of colloid chemistry in nanochemistry,” Usp. Khim. 69(11), 995–1008 (2000).

M. E. Mackay, A. Tuteja, P. M. Duxbury, C. J. Hawker, B. V. H. Horn, Z. Guan, G. Chen, and R. S. Krishnan, “General strategies for nanoparticle dispersion,” Science 311, 1740–1743 (2006).

A. V. Bystrova, N. V. Voronina, N. V. Gaevoi, E. V. Getmanova, V. M. Meshkov, O. B. Gorbatsevich, A. M. Muzafarov, A. N. Ozerin, E. V. Egorova, and E. A. Tatarinova, “Synthesis and control by molecular parameters of superbranch silicon-contained polymers and polymeric nanocomposites on their base,” Ross. Nanotekhnol. 3(5–6), 42–46 (2008).

A. M. Muzafarov, N. G. Vasilenko, E. A. Tatarinova, G. M. Ignat’eva, V. D. Myakushev, M. A. Obrezkova, O. B. Meshkov, N. V. Voronina, and O. V. Novozhilov, “Macromolecular nano-objects as a promising direction of polymer chemistry,” Polymer. Sci. C 53(1), 48 (2011).

R. G. Sinclair, “The case for polylactic acid as a commodity packaging plastic,” J. Macromolec. Sci. A 33, 585–597 (1996).

J. Lunt, “Large-scale production, properties and commercial applications of polylactic acid polymers,” Polymer Degradation Stability 59, 145–152 (1998).

R. A. Auras, B. Harte, S. Selke, and R. J. Hernandez, “Mechanical, physical, and barrier properties of poly(lactide) films,” J. Plastic Film Sheeting 19, 123–135 (2003).

E. Masuhara, K. Kojima, and N. Tarumi, “Shika Zairyo Kenkyu-jo Hokoku,” Rep. Res. Inst. Dental Mater. 2, 18 (1954).

I. B. Meshkov, V. V. Kazakova, O. B. Gorbatcevich, N. V. Voronina, V. D. Myakouchev, and A. M. Muza- farov, “MQ-type polymers based on hyperbranched polyethoxysiloxane and molecular silicasoles,” Polym. Prep. 47(2), 1152 (2006).

A. A. Askadskii, Computational Materials Science of Polymers (Cambridge Int. Sci. Publ., Cambridge, 2003).

A. A. Askadskii, Physical Properties of Polymers—Prediction and Control (Gordon and Breach Publ., Amsterdam, 1996).

A. A. Askadskii, Yu. I. Matveev, and M. S. Matevosyan, Vysokomolek. Soed. A 32(10), 2157–2166 (1990).

Yu. I. Matveev and A. A. Askadskii, Vysokomolek. Soed. A 36(3), 436–443 (1994).

A. A. Askadskii and V. I. Kondrashchenko, Computer Polymer Material Science, Vol. 1: Atomic-Molecular Level (Nauchnyi Mir, Moscow, 1999) [in Russian].

D. I. Svergun and L. A. Feigin, X-Ray and Neutron Low-Angular Scattering (Nauka, Moscow, 1986) [in Russian].

D. I. Svergun, “Determination of the regularization parameter in indirect-transform methods using perceptual criteria,” J. Appl. Crystallogr. 25, 495–503 (1992).

D. I. Svergun, “Restoring low resolution structure of biological macromolecules from solution scattering using simulated annealing,” Biophys. J. 76, 2879–2886 (1999).

M. B. Kozin and D. I. Svergun, “Automated matching of high- and low-resolution structural models,” J. Appl. Crystallogr. 34, 33–41 (2001).

L. J. Fetters, D. J. Lohes, and R. H. Colby, Physical Properties of Polymers Handbook (American Institute of Physics, Woodbury, NY, 1996).

B. K. Vainshtein, X-Rays Diffraction at Molecules Chains (Izd. Akademii Nauk SSSR, Moscow, 1963) [in Russian].

T. S. Kurkin, A. N. Ozerin, A. S. Kechek’yan, O. T. Gritsenko, L. A. Ozerina, G. G. Alkhanishvili, V. G. Sushchev, and V. Yu. Dolmatov, “The structure and properties of polymer composite fibers based on poly(vinyl alcohol) and nanodiamond of detonation synthesis,” Nanotech. Russ. 5(3–4), 340 (2010).

G. Allegra, G. Raos, and M. Vacatello, “Theories and simulations of polymer-based nanocomposites: from chain statistics to reinforcement,” Prog. Polym. Sci. 33, 683–731 (2008).

J. B. Hooper and K. S. Schweizer, “Theory of phase separation in polymer nanocomposites,” Macromolecules 39, 5133–5142 (2006).

S. H. Wu, Polymer 26(12), 1855–1863 (1985).

A. D. Pomogailo, A. S. Rozenberg, and I. E. Uflyand, Metals Nanoparticles in Polymers (Khimiya, Moscow, 2000) [in Russian].

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © A.S. Zhiltsov, I.B. Meshkov, T.S. Kurkin, O.B. Gorbatsevich, V.V. Kazakova, A.A. Askadskii, O.A. Serenko, A.N. Ozerin, A.M. Muzafarov, 2013, published in Rossiiskie Nanotekhnologii, 2013, Vol. 8, Nos. 9–10.

Rights and permissions

About this article

Cite this article

Zhiltsov, A.S., Meshkov, I.B., Kurkin, T.S. et al. Structure of polylactide-modified silicasol nanocomposites based on thermodynamically compatible components. Nanotechnol Russia 8, 644–654 (2013). https://doi.org/10.1134/S1995078013050157

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1995078013050157