Abstract

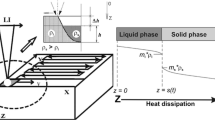

Numerical modeling of the processes of heat and mass transfer under the action of laser radiation on a titanium surface in a nitrogen medium has been performed. The problem statement includes a system of two-dimensional nonstationary nonlinear equations of heat conduction and diffusion with the corresponding initial and boundary conditions. The problem was solved taking into account the laser beam motion. The character of the distribution of the alloying elements in the zone of laser heating has been investigated. The results obtained make it possible to conclude that the concentrations of the alloying component are essentially inhomogeneous.

Similar content being viewed by others

References

Barashkov, A.S., Calculation of the Thermal Process of Steel Hardening at Heating by Uniformly Distributed Sources, Fiz. Khim. Obrab. Materialov, 2000, no. 4, pp. 82–89.

Kremnev, L.S., Vladimirova, O.V., Sagadeeva, T.G., Busurina, I.A., Kholodnov, E.V., and Mitauer, S.Ya., Hardening of the Work Surfaces of Plane-Parallel End Bars by Laser Radiation, Fiz. Khim. Obrab. Materialov, 1985, no. 3, pp. 13–16.

Shpis, Kh.-I., Tien, Kh. Le, and Birmann, Kh., Controlled Nitriding, Metalloved. Termich. Obrabotka Metallov, 2004, no. 7, pp. 7–11.

Bell, T., First Lecture of Lakhtin Memorial Lectures, Metalloved. Termich. Obrabotka Metallov, 1999, no. 7, pp. 6–16.

Khodakovskii, V.M. and Patenkova, E.P., Peculiarities of Laser Hardening of Cast-Iron Parts of Shipborn Technical Facilities, Novyye materialy i tekhnologii proizvodstva, 2003, no. 4, vol. 16, pp. 26–29.

Rykalin, N.N., Raschety teplovykh prozessov pri svarke (Calculations of Thermal Processes at Welding), Moscow, Mashgiz, 1951.

Dunaevskii, N.A. and Reshetin, V.P., Teplo-i massoperenos v poverkhnostnom sloe metallov pri lazernoi obrabotke (Heat and Mass Transport in the Surface Layer of Metals at Laser Treatment), Minsk, 1990.

Sakharov, A.N., The Influence of Phase Transition in Metal on Admixture Distribution at Laser Activation of the Processes of Diffusion Mass Transfer, Fiz. Khim. Obrab. Materialov, 1991, no. 4, pp. 53–59.

Lykov, A.M., Pochepayev, V.G., Red’kin, Yu.G., and Kuminov, E.S., Plasma Thermal Hardening of Steels, Fiz. Khim. Obrab. Materialov, 1997, no.3, pp. 27–32.

Kraposhin, V.S., Surface Treatment of Metallic Materials by Laser Radiation, Poverkhnost’. Fizika, Khimiya, Mekhanika, 1982, no. 3, pp.1–12.

Babichev, A.P., Babushkina, N.A., Bratkovsky, A.M., et al., Fizicheskiye velichiny: spravochnik (Physical Quantities: Reference Book), Grigor’ev, I.S. and Meilikhov, E.Z., Eds., Moscow: Energoatomizdat, 1991.

Samarskii, A.A., Teoriya raznostnykh skhem (Theory of Difference Schemes), Moscow: Nauka, 1983.

Paskonov, V.M., Polezhaev, V.I., and Chudov, L.A., Chislennoye modelirovaniye protsessov teplo-i massoobmena (Numerical Modeling of Heat and Mass Transport Processes), Moscow: Nauka, 1984.

Uglov, A.A., Peculiarities of the Pulsed Action of Laser Radiation on Metals, Fiz. Khim. Obrab. Materialov, 1998, no. 4, pp. 20–22.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Kuznetsov, G.V., Nagornova, T.A. Numerical modeling of high-temperature heat and mass transfer at laser nitriding of titanium. J. Engin. Thermophys. 16, 73–77 (2007). https://doi.org/10.1134/S1810232807020038

Issue Date:

DOI: https://doi.org/10.1134/S1810232807020038