Abstract

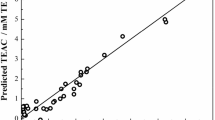

To predict monomer reactivity ratios in radical copolymerization of monomers M1 (C1H2=C2XY) with M2 (styrene), a support vector machine model was developed. After 16 quantum chemical descriptors were calculated by the density functional theory at B3LYP level of theory with 6–31G(d) basis set, the genetic algorithm method, together with multiple linear regression analysis, was used to select the best combinations of the variables. The optimal SVM model with four descriptors (\(q_{AC^1 }\), \(Q_{AC^2 }\), μ and E LUMO) was obtained with the Gaussian radical basis kernel (C = 8000, ɛ = 0.001 and γ = 0.01). The root-mean-square errors for training set, validation set and test set are 0.125, 0.123 and 0.188, respectively, which are more accurate than the existing artificial neural network model. Therefore, it is reasonable to predict monomer reactivity ratios with the support vector machine method.

Similar content being viewed by others

References

H. G. Elias, Macromolecules (Wiley, New York, 1977).

A. D. Jenkins and J. Jenkins, Macromol. Symp. 174, 187 (2001).

F. R. Mayo and F. M. Lewis, J. Am. Chem. Soc. 66, 1594 (1944).

T. Alfrey and C. C. Price, J. Polym. Sci. 2, 101 (1947).

A. D. Jenkins, J. Polym. Sci., Part A: Polym. Chem. 37, 113 (1999).

A. D. Jenkins and J. Jenkins, Macromol. Symp. 111, 159 (1996).

X. L. Yu, W. H. Yu, B. Yi, and X. Y. Wang, Collect. Czech. Chem. Commun. 74, 1279 (2009).

J. Brandrup, E. H. Immergut, and E. A. Grulke, Polymer Handbook (Wiley, New York, 1999).

M. J. Frisch, G. W. Trucks, H. B. Schlegel, et al., Gaussian 03, Rev. B.05 (Gaussian, Pittsburgh, 2003).

M. A. Turabekova and B. F. Rasulev, Molecules 9, 1194 (2004).

C. Cortes and V. Vapnik, Mach. Learn. 20, 273 (1995).

H. D. Li, Y. Z. Liang, and Q. S. Xu, Chemomet. Intel. Lab. Syst. 95, 188 (2009).

D. S. Cao, Q. S. Xu, Y. Z. Liang, X. Chen, and H. D. Li, J. Chemomet. 24, 584 (2010).

R. Kumar, A. Kulkarni, V. K. Jayaraman, and B. D. Kulkarni, J. Mol. Des. 3, 118 (2004).

X. L. Yu, Fiber Polym. 11, 757 (2010).

D. B. De Oliveira and A. C. Gaudio, Quant. Struct.-Act. Relat. 19, 599 (2000).

Q. Y. Tang and M. G. Feng, Practical Statistics and DPS Data Processing System (Science, Beijing, 2002).

M. Karelson, V. S. Lobanov, and A. R. Katritzky, Chem. Rev. 96, 1027 (1996).

N. Bodor, Z. Gabanyi, and C. K. Wong, J. Am. Chem. Soc. 111, 3783 (1989).

X. L. Yu, B. Yi, and X. Y. Wang, Eur. Polym. J. 44, 3997 (2008).

Author information

Authors and Affiliations

Corresponding author

Additional information

The article is published in the original.

Rights and permissions

About this article

Cite this article

Yu, X., Wang, X. A support vector machine model for the prediction of monomer reactivity ratios. Polym. Sci. Ser. B 53, 528 (2011). https://doi.org/10.1134/S1560090411090041

Received:

Accepted:

Published:

DOI: https://doi.org/10.1134/S1560090411090041