Abstract

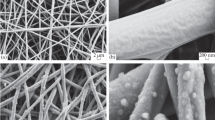

Conducting materials based on polypyrrole-modified nanofibers of polylactides of different molecular masses and copolymers of ε-caprolactam (–NH–(CH2)5–CO–) and hexamethylenediamine adipate (–H(CH2)6NHCO(CH2)4CO–) were prepared. As shown by scanning electron microscopy, oxidative polymerization of pyrrole on the polymer nanofiber matrix depends on the nanofib er hydrophilicity. The heterophase synthesis of polypyrrole on the surface of hydrophilic nanofibers of the aliphatic copolyamide allowed uniform coating of the material surface with polypyrrole nanoparticles. The surface resistivity of the composite material was about 0.4 kΩ sq–1.

Similar content being viewed by others

References

Sheikha, F.A., Macossaya, J., Cantua, T., et al., J. Mech. Behav. Biomed. Mater., 2015, vol. 41, pp. 189–198.

Macossaya, J., Sheikha, F.A., Cantua, T., et al., Appl. Surf. Sci., 2014, vol. 321, pp. 205–213.

Schiffman, J.D. and Schauer, C.L., Polym. Rev., 2008, vol. 48, pp. 317–352.

Scotheim, T., Elsenbaumer, R., and Reynolds, J., Handbook of Conducting Polymers, New York: Dekker, 1997.

Sata, T. and Yang, W., J. Membr. Sci., 2002, vol. 206, pp. 31–60.

Dobrovolskaya, I.P., Popryadukhin, P.V., Yudin, V.E., et al., J. Mater. Sci.: Mater. Med., 2015, vol. 26, no. 1, pp. 5381–5391.

Baumgartner, P.K., J. Colloid Interface Sci., 1971, vol. 36, pp. 71–79.

Popryadukhin, P.V., Popov, G.I., Dobrovolskaya, I.P., et al., Cardiovasc. Eng. Technol., 2015, vol. 7, no. 1, pp. 78–86.

Dobrovolskaya, I.P., Yudin, V.E., Popryadukhin, P.V., et al., J. Appl. Cosmet., 2016, vol. 1, pp. 1–7.

Vernitskaya, T.V. and Efimov, O.N., Russ. Chem. Rev., 1997, vol. 66, no. 5, pp. 443–457.

GOST (State Standard) 10589–87.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © V.V. Matrenichev, M.A. Shishov, P.V. Popryadukhin, I.Yu. Sapurina, E.M. Ivan’kova, I.P. Dobrovol’skaya, V.E. Yudin, 2017, published in Zhurnal Prikladnoi Khimii, 2017, Vol. 90, No. 10, pp. 1365−1370.

Rights and permissions

About this article

Cite this article

Matrenichev, V.V., Shishov, M.A., Popryadukhin, P.V. et al. Preparation of Conducting Composite Materials Based on Polymer Nanofibers and Polypyrrole. Russ J Appl Chem 90, 1680–1685 (2017). https://doi.org/10.1134/S1070427217100184

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1070427217100184