Abstract

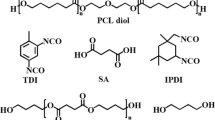

A three-step procedure for preparing polyurethanes with mixed polyether segments was suggested. It involves preparation of the “inverse” prepolymer by the reaction of one of oligodiisocyanates with 1,4-butanediol taken in a double excess, followed by the reaction with the other oligodiisocyanate. Polyurethanes with alternating poly(tetramethylene oxide) and poly(propylene oxide) soft segments were prepared by this procedure. Such materials surpass polyurethanes prepared from a mixture of oligodiisocyanates in the strength and softening point of the hard phase. In contrast to poly(tetramethylene oxide) urethane, elastomers with mixed polyether segments do not crystallize.

Similar content being viewed by others

References

Prisacariu, C., Polyurethane Elastomers: from Morphology to Mechanical Aspects, Springer, 2011.

Randall, D. and Lee, S., The Polyurethanes Book, New York: Wiley, 2003.

Lamba, N.M.K., Woodhouse, K.A., and Cooper, S.L., Polyurethanes in Biomedical Applications, CRC, 1998.

Zhang, H., Li, W., Yang, X., et al., J. Mater. Process. Technol., 2007, vol. 190, pp. 96–101.

Handbook of Plasticizers, Wypych, G., Ed, Toronto: ChemTec, 2012, 2nd ed.

Bagdi, K., Molnár, K., Sajó, I., and Pukánszky, B., eXPRESS Polym. Lett., 2011, vol. 5, no. 5, pp. 417–427.

Krol, P., Prog. Mater. Sci., 2007, vol. 52, pp. 915–1015.

Christenson, E.M., Anderson, J.M., Hiltner, A., and Baer, E., Polymer, 2005, vol. 46, no. 25, pp. 11744–11754.

Yilgör, I., Yilgör, E., and Wilkes, G.L., Polymer, 2015, vol. 58, pp. A1–A36.

Handbook of Solvents, vol. 1: Properties, Wypych, G., Ed, Toronto: ChemTec, 2014, 2nd ed.

Ahn, T.O., Jung, S.U., Jeong, H.M., and Lee, S.W., J. Appl. Polym. Sci., 1994, vol. 51, no. 1, pp. 43–49.

Tereshatov, V.V., Makarova, M.A., Senichev, V.Yu., et al., Colloid Polym. Sci., 2015, vol. 293, no. 1, pp. 153–164.

Zhao, C.T. and Pinho, M.N. d., Polymer, 1999, vol. 40, no. 22, pp. 6089–6097.

Gorna, K. and Gogolewski, S., J. Biomed. Mater. Res., 2002, vol. 60, no. 4, pp. 592–606.

Mayr, A.E., Cook, W.D., Edward, G.Y., and Murray, G.J., Polym. Int., 2000, vol. 49, pp. 293–301.

Luo, N., Wang, D.N., and Ying, S.K., Polymer, 1996, vol. 37, pp. 3045–3047.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © V.V. Tereshatov, A.I. Slobodinyuk, M.A. Makarova, Zh.A. Vnutskikh, A.V. Pinchuk, V.Yu. Senichev, 2016, published in Zhurnal Prikladnoi Khimii, 2016, Vol. 89, No. 6, pp. 784−789.

Rights and permissions

About this article

Cite this article

Tereshatov, V.V., Slobodinyuk, A.I., Makarova, M.A. et al. Characteristics of polyether urethanes with mixed soft segments, prepared by two- and three-step procedures. Russ J Appl Chem 89, 943–948 (2016). https://doi.org/10.1134/S1070427216060161

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1070427216060161