Abstract

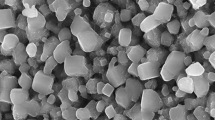

In order to develop a scientifically grounded technology for production of porous getters, there appears the necessity to apply highly sensitive methods for determining the activation temperature, which are compatible with the standard magnetron pumping technology. In this study, a complex technique for determining the activation temperature for porous getters is proposed using the experimental scheme simulating the conditions of porous getter activation in accordance with the standard exhaust tube pumping technology. Under the conditions of the simulation of physicochemical processes in the volume of the heated magnetron housing under pumping, the model of the formation of a gas load on the interior pumping equipment is considered. It is shown that, according to the theory of composite chemical reactions, thermal desorption flows are generated by either the theory of consecutive reactions or the theory of parallel-consecutive reactions. The sorption capacity of porous getters is determined from a plot as the time–temperature dependence of the mass yield of composite chemical reactions of interaction between the gas load and the surface and bulk of a getter tablet. A getter tablet’s change in mass is recorded using the microbalance of a vacuum thermogravimetric unit uninterruptedly at the frequency of one measurement a second throughout the entire period of measurements. The sensitivity threshold of the microbalance is 10–5 g and the maximum mass is 5 g. Using the theory of parallel-consecutive reactions, for the first time, the minimum temperature of thermal activation of a porous getter of a Ti–V (30 at %) alloy is determined, which is the main technological parameter when interior pumping equipment is employed. For the nonisothermal part of the standard heat treatment plot, at the heating rate of 10°C/min and the specified vacuum conditions, the minimum activation temperature is 393°C. For estimating the changes in the roughness of the free surface of a getter washer subjected to interior saturation in a hydrogen medium, scanning electron microscopy is used. Cracks and microsized tetragonal single crystals are found, which might be titanium hydrides TiН2. It is established that crack formation has a positive effect on the getter’s sorption activity due to the appearance of new atomically clean surfaces. However, cracking can contribute to the crumbling of the getter tablet. Therefore, the hydrogen gas load is the factor that limits the durability of the getter.

Similar content being viewed by others

REFERENCES

Zubkov, N.P., Pelipets, O.V., Bobyr’, N.P., and Spitsyn, A.V., Sorption and mechanical characteristics of titanium-vanadium getters, Elektron. Tekh., Ser. 1: SVCh-Tekh., 2013, no. 4 (519), pp. 154–161.

Petrov, V.S., A complex of measuring modules for determining the thermodynamic and kinetic constants of processes occurring in cathode, getter, superconducting, radar absorbing and sensor materials when heated in vacuum and under the influence of electric and magnetic fields, in Proceedings of the 2nd Russian-Japanese Seminar on Perspective Technologies, Materials and Equipments of Solid-State Electronic Components, Moscow: MISA, 2004, pp. 138–143.

Demikhov, K.E., Panfilov, Yu.V., Nikulin, N.K., et al., Vakuumnaya tekhnika: spravochnik (Vacuum Technology: A Guide), Demikhov, K.E. and Panfilov, Yu.V.., Eds., Moscow: Mashinostroenie, 2009. 3rd ed.

Polunina, A.A., Experimental determination of the fine mechanisms of hydrogen absorption by titanium to expand the range of operational characteristics of porous getters, Cand. Sci. (Tech. Sci.) Dissertation, Moscow: 2008.

Boyko, A., Gaev, D., Timoshenkov, S., et al., The study of different structuring techniques for creation of non-evaporable getters, Mater. Sci. Appl., 2013, vol. 4, no. 8a, pp. 57–61.

Brown, M., Dollimore, D., and Galwey, A., Reactions in the Solid State, Amsterdam: Elsevier, 1980.

Levinskii, Yu.V., Vnutrenneokislennye i vnutrenneazotirovannye nanomaterialy (Internally Oxidized and Internally Nitrated Nanomaterials), Moscow: EKOMET, 2007.

Petrov, V.S., Bykov, D.V., Kondrashova, O.I., et al., Osnovy materialovedeniya getternykh materialov. Ch. 1. Fiziko-khimicheskie osnovy getterirovaniya gazov metallami: ucheb. posobie (Fundamentals of Materials Science of Getter Materials. Part 1. Physicochemical Fundamentals of Gas Gettering by Metals, The School-Book), Moscow: MIEM, 2001.

Nesterov, A.V., High vacuum non-evaporable getter, Kratk. Soobshch. OIYaI, 1999, no. 1[93]-99, pp. 72–77.

ACKNOWLEDGMENTS

The authors thank V.I. Kotenev for providing the samples of porous getters.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by Z. Smirnova

Rights and permissions

About this article

Cite this article

Polunina, A.A., Petrov, V.S., Khanbekov, I.F. et al. Thermal Activation of Getters in Magnetron Production Technology. Russ Microelectron 49, 472–478 (2020). https://doi.org/10.1134/S1063739720070094

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1063739720070094