Abstract

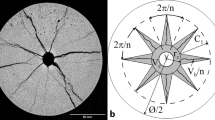

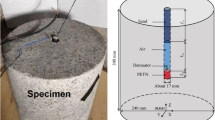

A physical model is created to describe stage-by-stage fracture of rock mass by deep-hole blasting. The analytical dependences are presented for main parameters of massive blasting. The zones of intense and passive crushing are identified in a blasted bench. The formulas are obtained to calculate volumes of different size particles in these zones. The automated determination procedure of particle size distribution is proposed. The program in Microsoft Visual Studio 2017 environment allows the automated analysis of blasthole pattern in a bench and particle size distribution in broken rock mass depending on initial data.

Similar content being viewed by others

References

Pokrovskii, G.I. and Fedorov, I.S. Deistvie udara i vzryva v deformiruemykh sredakh (Effect of Impact and Blasting in Deformable Media), Moscow, 1957.

Rodionov, V.N., Adushkin, V.V., and Kostyuchenko, V.N., Mekhanicheskii effekt podzemnogo vzryva (Mechanical Effect of Underground Blast), Moscow: Nedra, 1971.

Rakishev, B.R., Auezova, A.M., and Rakisheva, Z B., The Specification of Granulometric Composition of Natural Jointing in Rock Massif by Their Average Size, Proc. of the 9th Int. Conf. on Phys. Problems of Rock Destruction, Beijing, China, 2014, pp. 274–282.

Rakishev, B.R., Avtomatizirovannoe proektirovanie i proizvodstvo massovykh vzryvov na kar’erakh (Automated Engineering and Implementation of Large-Scale Blasting in Open Pit Mines), Almaty: Gylym, 2016.

Repin, N.Ya., Podgotovka i ekskavatsiya vskryshnykh porod ugol’nykh razrezov (Overburden Preparation and Excavation in Open Pit Coal Mines), Moscow: Nedra, 1978.

Kutuzov, B.N., Metody vedeniya vzryvnykh rabot (Blasting Methods), Part I: Rock Fragmentation by Blasting: University Textbook, Moscow: Gornaya kniga, 2007.

Komir, V.M. and Nazarenko, V.G., Role of Gaseous Products of Detonation in Fracture of Solid Medium by Blasting, Vzryvnoe delo, 1978, no. 80/37, pp. 74–80.

Efremov, E.I., Razrushenie gornykh porod energiei vzryva (Rock Fracture by Explosion Energy), Kiev: Naukova dumka, 1978.

Khanukaev, A.N., Fizicheskie protsessy pri otboike gornykh porod vzryvom (Physical Processes in Rock Breakage by Blasting), Moscow: Nedra, 1974.

Adushkin, V.V. and Spivak, A.A., Geomekhanika krupnomasshtabnykh vzryvov (Geomechanics of Large-Scale Blasts), Moscow: Nedra, 1993.

Trubetskoy, K.N. and Viktorov, S.D., Recent Problems of Rock Mass Fracture, Fizicheskie problemy vzryvnogo razrusheniya massivov gornykh porod (Physical Problems of Rock Fragmentation by Blasting), Moscow: IPKON RAN, 1999, pp. 7–17.

Adushkin, V.V., Budkov, A.M., and Kocharyan, G.G., Features of Forming an Explosive Fracture Zone in a Hard Rock Mass, J. Min. Sci., 2007, vol. 43, no. 3, pp. 273–28.

Viktorov, S.D. and Galchenko, Yu.P., Theory and Experimentation on Energy Distribution in Rock Mass in Process Blasting, Inzh. Fizika, 2018, no. 7, pp. 43–50.

Oparin, V.N., Adushkin, V.V., Yushkin, V.F., and Potapov, V.P., Influence of Natural Climate and Mining-Induced Impact on Mechanical Erosion and Seismic Noise in the Areas of Open Pit Coal Mines in Kuzbass, Mining Informational and Analytical Bulletin MIAB, 2019, no. 9, pp. 72–101.

Viktorov, S.D., Kazakov, N.N., Lapikov, I.N., and Shlyapin, A.V., Drilling-and-Blasting Engineering in Open Pit Mines, Vzryvnoe delo, 2014, no. 111/68, pp. 80–91.

Galushko, F.I., Komyachin, A.O., and Musatova, I.N., Quality Control in Rock Preparation by Basting Based on Optimized Blasting Patterns, Vzryvnoe delo, 2017, no. 118/75, pp. 140–151.

Zharikov, I.F., Regulation of Rock Fragmentation in Blasting by High Benches, Vzryvnoe delo, 2014, no. 111/68, pp. 93–100.

Dugartsyrenov, A.V. and Rakhmanov, R.A., Influence of Air Gaps on Blasting Efficiency, Vzryvnoe delo, 2019, no. 122/79, pp. 59–68.

Wei-Gang Shen, Tao Zhao, Giovanni Battista Crosta, and Feng Dai, Analysis of Impact-Induced Rock Fragmentation Using a Discrete Element Approach, Int. J. of Rock Mech. and Min. Sci., 2017, vol. 98, pp. 33–38.

Xie, L.X., Yang, S.Q., Gu, J.C., Zhang, Q.B., Lu, W.B., Jing, H.W., and Wang, Z.L., JHR Constitutive Model for Rock under Dynamic Loads, Computers and Geotechnics, 2019, vol. 108, pp. 161–172.

NET Framework Guide. Available at: https://docs.microsoft.com/en-us/dotnet/framework/index.

Lars Powers and Mike Snell, Microsoft Visual Studio 2015 Unleashed, 3rd Edition, Indianapolis, Imprint Sams, 2015.

Funding

The study was supported by the Ministry of Science and Education in the Republic of Kazakhstan within the framework of the Targeted Program of Technological and Production Modernization in the Mining and Processing Industries in Kazakhstan in 2018–2020, No. 2018/BR05235618.

Author information

Authors and Affiliations

Corresponding author

Additional information

Russian Text © The Author(s), 2020, published in Fiziko-Tekhnicheskie Problemy Razrabotki Poleznykh Iskopaemykh, 2020, No. 1, pp. 41–53.

Rights and permissions

About this article

Cite this article

Rakishev, B.R. Generation of Granulometric Composition of Broken Rocks in Fragmentation by Bench Blasting. J Min Sci 56, 36–46 (2020). https://doi.org/10.1134/S1062739120016466

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1062739120016466