Abstract

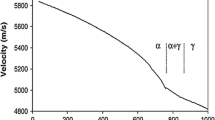

An ultrasonic testing (UST) method is proposed that allows one to classify internal defects in welded joints into planar and bulk ones by using defect scattering indicatrices. Dedicated angle twin-crystal transducers of the Duet type with probe angles of 29° and 61°, exciting a head wave in the test object, are employed as a transmitter and receiver for ultrasonic testing. Informative signs of defects based on using their scattering indicatrices are considered. These signs make it possible to improve the reliability of ultrasonic testing results. It is shown that due to the peculiarities of propagation of head waves, defect scattering indicatrices are most informative for the probe angle of 29° (a wedge angle close to the first critical value for the PMMA–aluminum-magnesium-alloy pair of materials) and the probe angle of 61° (the angle close to the value complementing the angle of 29° to 90°). The statistical significance of the results of calculating correlation and concordance coefficients were estimated for given significance levels \(\alpha = \) 0.05 and \(\beta = \) 0.05, where α and β are the probabilities of the errors of the first and second kind, respectively. Correlation matrices were compiled for the obtained defect scattering indicatrices. Additionally, the reliability of the results was verified by comparing the obtained data with a database of previously performed measurements and their results.

Similar content being viewed by others

REFERENCES

Ermolov, I.N., Vopilkin, A.Kh., and Ryzhov-Nikonov, V.I., Sb. mater. nauchno-tekhn. konf. “Voprosy metodiki i tekhniki ul’trazvukovoi spektroskopii” (Coll. Pap. Sci.-Tech. Conf. “Questions of Methods and Techniques of Ultrasonic Spectroscopy”), Kaunas, 1973. p. 19.

Shcherbinskii, V.G. and Belyi, V.E., New informative sign of the nature of defects in ultrasonic testing, Defektoskopiya, 1975, no. 3, pp. 27–37.

Vopilkin, A.Kh., Difraktsionnye metody v ul’trazvukovom nerazrushayushchem kontrole (Diffraction Methods in Ultrasonic Nondestructive Testing), Moscow: Izd. NTO Priborprom, 1989.

Gurvich, A.K., Dymkin, G.Ya., and Tsomuk, S.R., New informative feature of defect shape, Defektoskopiya, 1990, no. 11, pp. 3–7.

Perevalov, S.P., Study of geometrical and acoustic characteristics of erosion reflectors, Defektoskopiya, 1994, no. 9, pp. 15–31.

Ermolov, I.N., Vopilkin, A.Kh., and Badalyan, V.G., The evolution of tools and methods for determining the shape and size of defects in ultrasonic testing, Kontrol’ Diagn., 2003, no. 2, pp. 6–27.

Vopilkin, A.Kh., Badalyan, V.G., and Bazulin, E.G., Ul’trazvukovaya defektometriya metallov s primeneniem golograficheskikh metodov (Ultrasonic Characterization of Defects in Metals by Holographic Methods), Moscow: OOO NPTs Ekho+, 2008, pp. 27–28.

Badalyan, V.G., Bazulin, E.G., Vopilkin, A.Kh., et al., Ul’trazvukovaya defektometriya metallov s primeneniem golograficheskikh metodov (Ultrasonic Characterization of Defects in Metals by Holographic Methods), Vopilkin, A.Kh, Ed., Moscow: Mashinostroenie, 2008.

Bazulin, E.G., Kokolev, S.A., and Golubev, A.S., Application of an ultrasonic antenna array for registering echo signals by the double-scanning method for obtaining flaw images, Russ. J. Nondestr. Test., 2009, vol. 45, no. 2, pp. 86–97.

Braconnier, D., Detailed study of inspecting thick parts using large aperture phased arrays and DDF, in Braconnier, D., Okuda, S., and Dao, G., in 7th Int. Conf. on NDE in Relation to Structural Integrity for Nuclear and Pressurized Components, Yokohama, Japan, May 12–15, 2009.

Konovalov, N.N. and Meleshko, N.V., Visualization of defects of welded joints in ultrasonic testing with phased antenna arrays, MEGATECH Nov. Tekhnol. Industr. Diagn. Bezop., 2011, nos. 2–3, pp. 24–28.

ISO/DIS 16827: 2012. Nondestructive testing—Ultrasonic testing—Characterization and sizing of discontinuities.

Meleshko, N.V., Research and development of an ultrasonic technique for inspecting welded joints using flaw detectors equipped with antenna arrays (using example of inspecting welded joints of hoisting machines), Cand. (Eng.) Sci. Dissertation, November 5, 2013, Moscow: NUTs KASKAD, MGUPI, 2012.

Konovalov, N.N. and Meleshko, N.V., Measurement of the actual height of lacks of fusion in one-sided butt welded joints using ultrasonic flaw detectors with antenna arrays, V mire NK, 2013, no. 1, pp. 45–47.

Bazulin, E.G., Restoring the image of reflectors using the C-SAFT method during multiple reflection of echo signals from the boundaries of a cylindrical inspection object, Russ. J. Nondestr. Test., 2013, vol. 49, no. 2, pp. 77–92.

Scherbinskii, V.G., Tekhnologiya ul’trazvukovogo kontrolya svarnykh soyedinenii (Technology of Ultrasonic Testing of Welded Joints), St. Petersburg: SVEN, 2014.

Bazulin, E.G., Development of a system of operational ultrasonic nondestructive testing with enhanced information value using antenna arrays, Cand. (Eng.) Sci. Dissertation, Mocow: NPTs Ekho+, 2014.

Metodicheskie rekomendatsii o poryadke provedeniya ul’trazvukovogo kontrolya metallicheskikh konstruktsii tekhnicheskikh ustroistv, zdanii i sooruzhenii (Methodological Recommendations on the Procedure for Conducting Ultrasonic Inspection of Metal Frames of Technical Devices, Buildings, and Structures), NTTs Bezop. Prom-sti, 2015, Ser. 32, no. 11.

Bazulin, E.G., Vopilkin, A.Kh., and Tikhonov, D.S., Improving the reliability of ultrasonic testing. Part 1. Determination of the type of discontinuity in ultrasound testing with antenna arrays, Kontrol’ Diagn., 2015, no. 8, pp. 7–21.

Official website of EXTENDE company. URL: http://www.extende.com/civa-2 (accessed February 14, 2019).

Aleshin, N.P., Belyi, V.E., Vopilkin, A.Kh., et al., Metody akusticheskogo kontrolya metallov (Methods of Acoustic Testing of Metals), Aleshin, N.P., Ed., Moscow: Mashonostroenie, 1989.

Gurvich, A.K. and Kuz’mina, L.I., Scattering indicatrices as a source of additional information about revealed defects, Defektoskopiya, 1970, no. 6, pp. 47–56.

Nemytova, O.V., Rinkevich, A.B., and Perov, D.V., RF Patent no. 2524451, G01N29/00, Method for determining the type of defect in metal products, Byull. Izobret., 2014, no. 21.

Wustenberg, H.A. and Mundry, E., Nondestructive Testing, 1973.

Krautkramer,J.H., Werkstoffprufung mit ultrashall. Funfte, Neubearbeitete Auflage unter Mitarbeit von, Berlin–Heidelberg–New York–London–Paris–Tokyo: Springer-Verlag, 1986.

Bezopasnost’ Rossii. Pravovyye, sotsial’no-ekonomicheskiye i nauchno-tekhnicheskiye aspekty. Bezopasnost’ promyshlennogo kompleksa (Security of Russia. Legal, Socio-Economic and Scientific and Technical Aspects. Industrial Safety) Moscow: MGF Znanie, NTTs Bezop. Prom-sti Gosgortekhnadzor Ross., 2002.

Konovalov, N.N., Rafikov, R.Kh., Preobrazhenskii, M.N., RF Patent No. 2581083. A method for determining the shape of defect scattering indicatrix under ultrasound testing and a device for its implementation, Byull. Izobret., 2016, no. 10.

Lange, Yu.V. and Voronkov, V.V., Kontrol’ nerazrushayushchii akusticheskii. Terminy i opredeleniya/Spravochnik (Nondestructive Acoustic Testing. Terms and Definitions. Handbook), Moscow: author’s publication, 2003.

Razygraev, N.P. and Razygraev, A.N., Acceptance and operational ultrasonic testing using head waves in echo technique, V mire NK, 2007, no. 4, pp. 8–12.

Ermolov, I.N., Razygraev, V.G., and Shcherbinskii, V.G., Use of acoustic waves of head type for ultrasonic testing, Defektoskopiya, 1978, no. 1, pp. 33–40.

Meleshko, N.V. and Rafikov, R.Kh., Assessment of the possibility of replacing the ultrasonic method of radiation monitoring of various types of welded joints in ship structures, in Sb. tr. nauchno-prakt. konf. “Aktual’nye problemy priborostroeniya, informatiki i sotsial’no-ekonomicheskikh nauk” (Proc. Sci.-Pract. Conf. “Topical Problems of Instrument Engineering, Computer Science, and Socioeconomic Sciences”) Moscow: MGUPI, 2013, pp. 96–103.

Samokrutov, A.A. and Shevaldykin, V.G., Scanning in ultrasonic tomography, V mire NK, 2010, no. 3 (49), pp. 7–10.

GOST (State Standard) 14806–80. Arc welding of aluminum and aluminum alloys in inert gases. Welded joints. Main types, structural elements, and dimensions (with Amend. no. 1 of December 1990). Replaced GOST 14806-69. Enacted January 7, 1981, Moscow: Izd. Standartov, 1981.

OST5-9153-84. Joints in welded hull structures. Arc welding of aluminum alloys in protective gases. Main provisions. Replaced OST5.9153-73. Enacted January 1, 1986, Moscow: Izd. Standartov, 1986.

Voronkov, V.A., Voronkov, I.V., Kozlov, V.N., Samokrutov, A.A., and Shevaldykin, V.G., On the applicability of antenna array technology in ultrasonic testing of hazardous production facilities, V mire NK, 2011, no. 1 (51), pp. 64–70.

Rafikov, R.Kh., Influence of the depth of corner reflectors on the angle of the maximum of their scattering indicatrices, Kontrol’ Diagn., 2016, no. 11, pp. 34–41.

Konovalov, N.N., Rafikov, R.Kh., Preobrazhenskii, M.N., and Makarov, S.A., Determination of the nature of defects in metals and welded joints using piezoelectric transducers, Tekhnol. Tekhnosfer. Bezop., Acad. State Fire Serv. Minist. Emerg. Situat. Russ., 2015, no. 4 (62). http://agps-2006. narod.ru/ttb/2015-4/29-04-15.ttb.pdf

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by V. Potapchouck

Rights and permissions

About this article

Cite this article

Rafikov, R.K. Improving the Efficiency of Ultrasonic Testing Based on Additional Information on Defect Scattering Indicatrices. Russ J Nondestruct Test 55, 353–362 (2019). https://doi.org/10.1134/S1061830919050097

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1061830919050097