Abstract

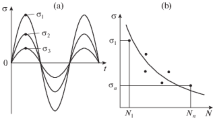

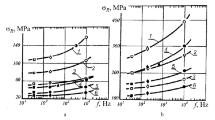

The paper analyzes the scale hierarchy of transitions from very high to high and low cycle fatigue which are taken as fatigue limit according to the Wöhler concept. The analysis shows that the life distribution in the transition range 106–108 cycles is multimodal. From relations between the fatigue limit σ–1 and mechanical characteristics σU and σ0.2 in aircraft materials based on Fe, Al, Mg, Ti, and Cu it follows that σ–1 depends on σU and σ0.2 and the ratio σ–1/σ0.2 depends on σ0.2/σU. As σ–1/σ0.2 increases, the complete diagram of three fatigue scales degrades. The transition from very high to low cycle fatigue goes without high cycle fatigue at σ–1/σ0.2 ≥ 1.

Similar content being viewed by others

REFERENCES

Machine Building, Encyclopedia, Vol. II-1: Physico-Mechanical Properties. Testing of Metallic Materials, Mamaeva, E.I, Ed., Moscow: Mashinostroenie, 2010.

RF GOST 25.502-79: Strength Analysis and Testing in Machine Building. Methods of Metals Mechanical Testing. Methods of Fatigue Testing, 2005.

Bathias, C. and Paris, P.C., Gigacycle Fatigue in Mechanical Practice, New York: Marcel Dekker, 2005.

Proceedings of the III International Conference on Very High Cycle Fatigue (VHCF-3), September 16–19, 2004, Ritsumeikan University, Kusatsu, Japan, Sakai, T. and Ochi, Y., Eds., Japan: The Society of Materials Science, 2004.

Proceedings of the VI International Conference on Very High Cycle Fatigue (VHCF-4), August 19–22, 2007, University of Michigan, Ann Arbor, Michigan, USA, Allison, J.E., Jones, J.W., Larsen, J.M., and Ritchie, R.O., Eds., Ann Arbor: TMS, 2007.

Proceedings of the VII International Conference on Very High Cycle Fatigue (VHCF-7), July 3–5, 2017, Dresden, Germany, Zimmermann, M. and Christ, H.-J., Eds., Dresden: DVM, 2017.

Shanyavskiy, A., Ultrahigh Plasticity Behavior of Metallic Materials in the Ultra-High-Cycle (or Gigacycle, Very-High-Cycle) Fatigue Regime,Key Eng.Mater., 2016, vol. 664, pp. 231–245.

Shanyavsky, A.A., Scales of Metal Fatigue Cracking,Phys. Mesomech., 2015, vol. 18, no. 2, pp. 163–173.

Mughrabi, H., Specific Features and Mechanisms of Fatigue in the Ultrahigh-Cycle Regime, Int. J. Fatigue, 2006, vol. 28(11), pp. 1501–1508.

Panin, V.E., Overview on Mesomechanics of Plastic Deformation and Fracture of Solids, Theor. Appl. Fract. Mech., 1998, vol. 30(1), pp. 1–11.

Palmgren, A.G., Die Lebensdauer von Kugellagern,Zeitschrift des Vereines Deutscher Ingenieure (VDI Zeitschrift), 1924, vol. 68, no. 14, pp. 339–341.

Miner, M.A., Cumulative Damage in Fatigue, J. Appl. Mech. A, 1945, pp. 159–164.

Shanyavsky, A.A., Safe Operation of First-Stage LPC Disks of D-30KU Engines by Fatigue Crack Growth Criteria,Probl. Bezopasn.Polyot., 2011, no. 1, pp. 20–49.

Shanyavskiy, A.A., Fatigue Crack Propagation in Turbine Disks of EI698 Superalloy, Frattura Integrità Strutturale, 2013, vol. 7, no. 24, pp. 13–25.

Shanyavskiy A.A., Safe Fatigue Failure of Aircraft Structures, Ufa: Monograph, 2003.

Marci, G., Non-Propagation Conditions (ΔKth) and Fatigue Crack Propagation Threshold (δKT), Fatigue Fract. Eng. Mater. Struct., 1994, vol. 17, no. 8, pp. 891–908.

Panin, V.E., Synergetic Principles of Physical Mesomechanics,Phys. Mesomech., 2000, vol. 3, no. 6, pp. 5–34.

Shanyavsky, A.A., Simulation of Fatigue Fracture of Metals. Synergetics in Aviation, Ufa: Monograph, 2007.

Shabalin, V.I., Experimental Investigation of Fatigue Curve Shape, in Strength of Metals under Cyclic Loading, Ivanova, V.S., Ed., Moscow: Nauka, 1967, pp. 162–169.

Ivanova, V.S. and Terentiev, V.F., Nature of Fatigue of Metals, Moscow: Metallurgia, 1975.

Terentiev, V.F., General Fatigue Mechanisms in BCC Metals, inCyclic Fracture Toughness of Metals and Alloys, Moscow: Nauka, 1981, pp. 45–52.

Yokobori, T., An Interdisciplinary Approach to Fracture and Strength of Solids, Groningen: Wolters-Noordhoff Scientific Publ., 1968.

Phillips, W.L. and Armstrong, R.W., The Influence of Specimen Size, Polycrystal Grain Size, and Yield Point Behaviour on the Fatigue Strength of Low-Carbon Steel, J. Mech. Phys. Solids, 1969, vol. 17, no. 4, pp. 265–270.

Shanyavskiy, A., Zaharova, T., and Potapenko, Yu., The Nature of Multi-Modal Distribution of Fatigue Durability for Titanium Alloy VT9, in Proceedings of the Forth International Conference on Very High Cycle Fatigue (VHCF-4), August 19–22, 2007, University of Michigan, Ann Arbor, Michigan, USA, Allison, J.E., Jones, J.W., Larsen, J.M., and Ritchie, R.O., Eds., TMS, 2007, pp. 325–330.

Nikitin, A., Palin-Luc, T., and Shanyavskiy, A., Crack Initiation in VHCF Regime on Forged Titanium Alloy under Tensile and Torsion Loading Modes, Int. J. Fatigue, 2016, vol. 93(2), pp. 318–325.

Nikitin, A., Palin-Luc, T., Shanyavskiy, A., and Bathias, C., Comparison of Crack Paths in a Forged and Extruded Aeronautical Titanium Alloy Loaded in Torsion in the Gigacycle Fatigue Regime,Eng. Fract. Mech., 2016, vol. 167, pp. 259–272.

Panin, V.E., Physical Mesomechanics of Materials (in 2 vol.), Tomsk: TSU, 2015.

Panin, V.E., Panin, A.V., and Moiseenko, D.D., Physical Mesomechanics of a Deformed Solid as a Multilevel System. II. Chessboard-Like Mesoeffect of the Interface in Heterogeneous Media in External Fields, Phys. Mesomech., 2007, vol. 10, no. 1–2, pp. 5–14.

Zakharova, T.P., On the Problem Concerned with the Statistical Nature of Fatigue Damage of Steels and Alloys, Strength Mater., 1974, vol. 6, no. 4, pp. 415–421.

Troshchenko, V.T. and Sosnovsky, L.A., Fatigue Resistance of Metals and Alloys, Handbook, Kiev: Naukova Dumka, 1987, Part 1.

Aircraft Materials, Handbook (in 9 vol.), Tumanov, A.T., Ed., Moscow: VIAM, 1975.

Funding

The work was supported by RSF, grant No. 19-19-00705.

Author information

Authors and Affiliations

Corresponding author

Additional information

Russian Text © The Author(s), 2019, published in Fizicheskaya Mezomekhanika, 2019, Vol. 22, No. 1, pp. 44–53.

Rights and permissions

About this article

Cite this article

Shanyavskiy, A.A., Soldatenkov, A.P. Scales of Metal Fatigue Limit. Phys Mesomech 23, 120–127 (2020). https://doi.org/10.1134/S1029959920020034

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1029959920020034