Abstract

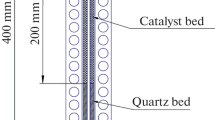

Production of synthetic diesel fuel by the Fischer–Tropsch (FT) method in the presence of a composite catalyst prepared by mechanically mixing 35 wt % Co/SiO2, 30 wt % HZSM-5, and 30 wt % Al2O3 has been studied. The catalyst has been characterized by the H2 TPR, H2 TPD, NH3 TPD, XRD, SEM, and TEM methods. Catalytic properties have been studied in a fixed-bed flow reactor at 2 MPa and a GHSV of 1000 h–1 in the temperature range of 230–250°C. The highest efficiency and C5+ HC selectivity values of 130 kg/(m3 h) and 72.5%, respectively, are achieved at 250°C. The low-temperature properties of the synthetic diesel fuel meet the requirements for winter diesel.

Similar content being viewed by others

References

Energy Strategy of Russia until 2035 (Basics) (Minenergo, Moscow, 2015) [in Russian].

A. V. Kameshkov and A. A. Gaile, Izv. SPbGTI (Tech. Univ.), No. 29, 49 (2015).

A. F. Kemalov, R. A. Kemalov, D. Z. Valiev, and I. M. Abdrafikova, Life Sci. J. 11, 461 (2014).

T. P. Kiseleva, R. R. Aliev, and M. I. Tselyutina, Neftepererab. Neftekhim., No. 2, 3 (2016).

J. Ellepola, N. Thijssen, J. Grievink, et al., Comput. Chem. Eng. 42, 2 (2012).

A. P. Savost’yanov, R. E. Yakovenko, G. B. Narochnyi, et al., RU Patent No. 20161503741 (2017).

A. P. Savost’yanov, R. E. Yakovenko, S. I. Sulima, et al., Catal. Today 279, 107 (2017).

G. B. Narochnyi, A. P. Savost’yanov, R. E. Yakovenko, and V. G. Bakun, Catal. Ind. 8, 139 (2016).

S. Sartipi, J. E. Dijk, J. Gascon, and F. Kapteijn, Appl. Catal., A 456, 11 (2013).

The Rietveld Method, Ed. by R. A. Young (Oxford: Oxford University Press, 1995).

D. Xu, W. Li, H. Duan, et al., J. Catal. Lett. 102, 229 (2005).

J. P. Breejen, P. B. Radstake, G. L. Bezemer, et al., J. Am. Chem. Soc. 131, 7197 (2009).

F. Diehl and A. Y. Khodakov, Oil Gas Sci. Technol. Rev. 64, 11 (2009).

A. P. Savost’yanov, R. E. Yakovenko, G. B. Narochnyi, et al., Kinet. Catal. 58, 81 (2017).

F. Lonyi and J. Valyon, Microporous Mesoporous Mater. 47, 293 (2001).

D. A. Tarakanov, L. V. Sineva, and A. Yu. Krylova, Katal. Prom–sti., No. 3, 18 (2006).

E. Rytter and A. Holmen, ACS Catal. 7, 5321 (2017).

E. Iglesia, Stud. Surf. Sci. Catal. 107, 53 (1997).

G. V. Echevskii, A. V. Toktarev, D. G. Aksenov, and E. G. Kodenev, Katal. Prom–sti. 17, 236 (2017).

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © A.P. Savost’yanov, G.B. Narochnyi, R.E. Yakovenko, A.N. Saliev, S.I. Sulima, I.N. Zubkov, S.V. Nekroenko, S.A. Mitchenko, 2017, published in Neftekhimiya, 2017, Vol. 57, No. 6, pp. 809–812.

Rights and permissions

About this article

Cite this article

Savost’yanov, A.P., Narochnyi, G.B., Yakovenko, R.E. et al. Synthesis of Low-Pour-Point Diesel Fuel in the Presence of a Composite Cobalt-Containing Catalyst. Pet. Chem. 57, 1186–1189 (2017). https://doi.org/10.1134/S0965544117060251

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0965544117060251