Abstract

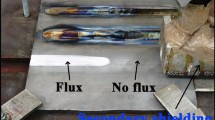

The effects of three activating fluxes, SiO2, TiO2, and MoO3, in tungsten inert gas (TIG) welding process on penetration, morphology, and mechanical properties of weld joint were investigated by bead on plate welding on 2219 aluminum alloy. Experimental results showed that a noticeable increase in the weld penetration and depth to with ratio was obtained by using activating fluxes. Among all the activating fluxes used in this study, the maximum penetration was achieved in case of SiO2 flux. The microstructure analysis demonstrated that oxide fluxes can promote transition from columnar to equiaxed grain growth in the fusion zone. It is also found that A–TIG weldments exhibit superior mechanical properties including tensile strength and hardness than those of TIG welding without flux.

Similar content being viewed by others

REFERENCES

F. C. Campbell, Light Weight Materials (ASM International, Ohio, 2012).

P. S. Rao, K. G. Sivadasan, and P. K. Balasubramanian, “Structure–property correlation on AA 2219 aluminum alloy weldments,” Bull. Mater. Sci. 19, 549–557 (1996).

E. Ahmadi and A. R. Ebrahimi, “Welding of 316L austenitic stainless steel with activated tungsten inert gas process,” J. Mater. Eng. Perform. 24, 1065–1071 (2015).

S. Tathgir, A. Bhattacharya, and T. K. Bera, “Influence of current and shielding gas in TiO2 flux activated TIG welding on different graded steels,” Mater. Manuf. Processes 30, 11–15 (2015).

A. Kulkarni, D. K. Dwivedi, and M. Vasudevan, “Study of mechanism, microstructure and mechanical properties of activated flux TIG welded P91 Steel-P22 steel dissimilar metal joint,” Mater. Sci. Eng., A 731, 309–323 (2018).

S. Z. Li, J. Shen, Z. M. Cao, and L. Z. Wang, “Effects of mix activated fluxes coating on microstructures and mechanical properties of tungsten inert gas welded AZ31 magnesium alloy joints,” Sci. Technol. Weld. Joining 17, 467–475 (2012).

K. D. Ramkumar, B. M. Kumar, M. G. Krishnan, S. Dev, A. J. Bhalodi, N. Arivazhagan, and S. Narayanan, “Studies on the weldability, microstructure and mechanical properties of activated flux TIG weldments of Inconel 718,” Mater. Sci. Eng., A 639, 234–244 (2015).

H. L. Lin and T. M. Wu, “Effects of activating flux on weld bead geometry of Inconel 718 alloy TIG welds,” Mater. Manuf. Processes 27, 1457–1461 (2012).

X. Gao, J. Dong, and X. Han, “Effect of RE2O3 (RE = La, Ce) fluxes on A-TIG welding of Ti–6Al–4V,” Int. J. Adv. Manuf. Technol. 91, 1181–1188 (2017).

Y. Yin, D. Zhang, G. Yu, W. Wu, and W. Qu, “Porosity free direct current A-TIG welding of 2219 aluminum alloy,” Trans. China Weld. Inst. 38, 61–64 (2017).

H. Li, J. Zou, J. Yao, and H. Peng, “The effect of TIG welding techniques on microstructure, properties and porosity of the welded joint of 2219 aluminum alloy,’ J. Alloys Compd. 727, 531–539 (2017).

A. V. S. Babu, P. R. Narayanan, and S. V. S. Narayana Murty, “Development of flux bounded tungsten inert gas welding process to join aluminum alloys,” Amer. J. Mech. Ind. Eng. 1, 58–63 (2016).

D. S. Howse and W. Lucas, “Investigation into arc constriction by active fluxes for tungsten inert gas welding,” Sci. Technol. Weld. Joining 5, 189–193 (2000).

C. Heiple and J. Roper, “Mechanism for minor element effect on GTA fusion zone geometry,” Weld. J. 61, 97–108 (1982).

D. K. Aidun and S. A. Martin, “Effect of sulfur and oxygen on weld penetration of high-purity austenitic stainless steels,” J. Mater. Eng. Perform. 6, 496–502 (1997).

S. A. David and J. M. Vitek, “Correlation between solidification parameters and weld microstructures,” Int. Mater. Rev. 34, 213–245 (1989).

G. W. Delamore and R. W. Smith, “The mechanism of grain refinement in dilute Al alloys,” Metall. Trans. 2, 1733–1738 (1971).

S. R. Koteswara Rao, G. Madhusudhan Reddy, P. Srinivasa Rao, M. Kamaraj, and K. Prasad Rao, “Improving mechanical properties of 2219 aluminum alloy GTA welds by scandium addition,” Sci. Technol. Weld. Joining 10, 418–426 (2005).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ahmadi, E., Ebrahimi, A.R. & Hoseinzadeh, A. Microstructure Evolution and Mechanical Properties of 2219 Aluminum Alloy A–TIG Welds. Phys. Metals Metallogr. 121, 483–488 (2020). https://doi.org/10.1134/S0031918X20050026

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X20050026