Abstract

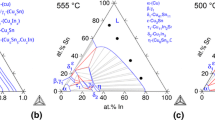

Quenched titanium–ruthenium alloys containing 0.25–4 at % ruthenium have been studied using X-ray diffraction analysis, optical metallography, transmission electron microscopy, and microhardness measurements. It has been found that, during the quenching of the alloys containing 0.25, 0.5, and 1 at % ruthenium, a polymorphic β → α transformation occurs with the formation of a two-phase (α + β) structure. In Ti–1.5 at % Ru and Ti–2 at % Ru alloys, a martensitic β → α″ transformation occurs. The quenched Ti–3 at % Ru alloy has a β + ω structure. The complete stabilization of the β phase takes place in the alloy with 4 at % ruthenium. In the electron-diffraction patterns of alloy containing 4 at % ruthenium, diffuse scattering that indicates the formation of ω-phase-related displacements in the locations of atoms has been observed.

Similar content being viewed by others

References

A. V. Dobromyslov and V. A. Elkin, “β → α and β → ω transformations in Ti–Os alloys,” Metall. Mater. Trans. A 30, 231–233 (1999).

A. V. Dobromyslov and N. I. Taluts, “Structure of quenched alloys of the Ti–Pd system,” Fiz. Met. Metallogr. 117 (7), 693–700 (2016).

A. V. Dobromyslov and V. A. Elkin, “Martensitic transformation and metastable β-phase in binary titanium alloys with d-metals of 4–6 periods,” Scr. Mater. 44, 905–910 (2001).

A. V. Dobromyslov and V. A. Elkin, “The orthorhombic a?-phase in binary titanium-base alloys with d-Metals of V–VIII Groups,” Mater. Sci. Eng., A 438–440, 324–326 (2006).

V. N. Eremenko, T. D. Shtepa, and V. G. Sirotenko, “On the intermediate phases in titanium alloys with iridium, rhodium, and osmium,” Poroshk. Metall., No. 6, 68–72 (1966).

A. I. Antipov and V. N. Moiseev, “On the coefficient of stablization β of titanium alloys,” Metalloved. Term. Obrab. Met., No. 12, 2–5 (1997).

L. N. Guseva and L. K. Dolinskaya, “Metastable phases in titanium alloys with Group VIII elements quenched from the β field,” Izv. Akad. Nauk SSSR. Met., No. 6, 195–202 (1974).

E. Raub and E. Roschel, “Die Legierungen des Rutheniums mit Titan und Zirconium,” Z. Metallkd. 54, 455–462 (1963).

L. N. Guseva, N. G. Boriskina, and L. K. Dolinskaya, “Metastable phases in titanium-rich Ti–Ru alloys,” Izv. Akad. Nauk SSSR, Met., No. 3, 215–217 (1973).

N. G. Boriskina and I. I. Kornilov, “On the Ti–Ru phase diagram,” Izv. Akad. Nauk SSSR, Met., No. 2, 214–217 (1976).

Phase Diagrams of Binary Metal Systems: A Handbook, Ed. by N.P. Lyakishev, Vol. 3, Book 2 (Mashinostroenie, Moscow, 1999) [in Russian].

I. I. Novikov, Theory of Heat Treatment (Metallurgiya, Moscow, 1974) [in Russian].

Yu. D. Tyapkin, “Electronography,” in Itogi nauki i tekhniki. Ser.: Metallovedenie i termicheskaya obrabotka, vol. 11 (VINITI, Moscow, 1977), pp. 152–214 [in Russian].

H. J. Lee and H. I. Aaronson, “Eutectoid Decomposition Mechanisms in Hypoeutectoid Ti–X Alloys,” J. Mater. Sci. 23, 150–160 (1988).

G. W. Franti, J. C. Williams, and H. I. Aaronson, “A Survey of Eutectoid Decomposition in Ten Ti–X Systems,” Metall. Trans. A 9, 1641–1649 (1978).

A. V. Dobromyslov and N. V. Kazantseva, “Phase Transformations in the Ti–Cu System,” Fiz. Met. Metalloved. 89, 467–473 (2000).

A. V. Dobromyslov, “Phase transformations and structure of titanium alloys,” in New promising materials and new technologies, Ed. by N. I. Noskova (UrO RAN, Ekaterinburg, 2001) [in Russian].

M. Enomoto and M. Fujita, “Analysis of the composition of a plates isothermally formed in titanium binary alloys,” Metall. Trans. A 21, 1547–1555 (1990).

E. V. Collins, Physical Metallurgy of Titanium Alloys (Metallurgiya, Moscow, 1988) [in Russian].

N. I. Taluts, A. V. Dobromyslov, and V. A. Elkin, “Structural and phase transformations in quenched and aged Zr-Ru alloys,” J. Alloys Compd. 282, 187–196 (1999).

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © A.V. Dobromyslov, N.I. Taluts, 2018, published in Fizika Metallov i Metallovedenie, 2018, Vol. 119, No. 3, pp. 285–295.

Rights and permissions

About this article

Cite this article

Dobromyslov, A.V., Taluts, N.I. Structure of Quenched Ti–Ru Alloys. Phys. Metals Metallogr. 119, 272–281 (2018). https://doi.org/10.1134/S0031918X18030043

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X18030043