Abstract

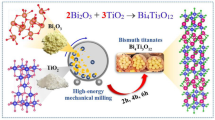

The microstructure of an a-TiO2:ZnO system obtained by two different synthesis techniques is investigated. Equimolar a-TiO2:ZnO is subjected to high-energy planetary ball milling as a dry mechanical technique and a solvothermal method as a wet technique for preparing zinc titanates. The investigation is performed by XRD and HR-TEM. The mechanical route results in the formation of ZnTiO3 as a major product accompanied by Zn2Ti3O8 as a minor one. The solvothermal route results in the formation of Zn2Ti3O8 accompanied by traces of zincite. The thermal stability of later zinc titanate is explored under different temperatures and results in a homogeneous amorphous nanocrystalline phase transformation without a compositional change.

Similar content being viewed by others

References

S. K. Manik and S. K. Pradhan. Physica E, 2006, 33(1), 69–76.

H. T. Kim, J. D. Byun, and Y. Kim. Mater. Res. Bull., 1998, 33(6), 963–973.

C. Karunakaran, G. Abiramasundari, P. Gomathisankar, G. Manikandan, and V. Ananthi. Mater. Res. Bull., 2011, 46, 1586–1592.

Z. Liu, D. Zhou, S. Gong, and H. Li. J. Alloy Compd., 2009, 475(1), 840–845.

S. Moradi, P. Aberoomand-Azar, S. Raeis-Farshid, S. Abedini-Khorrami, and M. Hadi Givianrad. J. Saudi Chem. Soc., 2016, 20(4), 373–378.

D. L. Liao, C. A. Badour, and B. Q. Liao. J. Photochem. Photobiol. A, 2008, 194(1), 11–19.

Y. S. Chang, Y. H. Chang, I. G. Chen, G. J. Chen, and Y. L. Chai. J. Cryst. Growth., 2002, 243(2), 319–326.

S. Sen, M. L. Ram, S. Roy, and B. K. Sarkar. J. Mater. Res., 1999, 14(03), 841–848.

J. Tian, L. Chen, Y. Yin, X. Wang, J. Dai, Z. Zhu, X. Liu, and P. Wu. Surface Coat. Technol. Alert., 2009, 204(1), 205–214.

A. I. Sheinkman, F. P. Sheinkman, and I. P. Dobrovol’skii. Izv. ANSSSR, Neorgan. Mater., 1977, 13(8), 1447–50.

M. H. Liao, C. H. Hsu, and D. H. Chen. J. Solid State Chem., 2006, 179, 2020–2026.

O. Yamaguchi, M. Morimi, H. Kawabata, and K. Shimizu. J. Am. Ceram. Soc., 1987, 70, 97/98.

R. K. Datta. Final Report under US Department of Energy Contract No. DE-AP21-93MC53415. Virginia Polytechnic Institute, State University, Blacksburg, VA, 24060, 1994.

Dong Qian, L. Gerward, and J. Z. Jiang. J. Mater. Sci., 2004, 39, 5389–5392.

Iwasaki Mitsunobu, Yoichi Inubushi, and Seishiro Ito. J. Mater. Soi. Lett., 1997, 16(18), 1503–1505.

C. C. Chen, J. F. Liu, P. Liu, and B. H. Yu. Adv. Chem. Eng. Sci., 2011, 1, 9–14.

P. K. Giri, S. Bhattacharyya, K. Dilip Singh, R. Kesavamoorthy, B. K. Panigrahi, and K. G. M. Nair. J. Appl. Phys., 2007, 102(9), 093515.

S. Begin-Colin, T. Girot, G. Le Caër, and A. Mocellin. J. Solid State Chem., 2000, 149, 41.

Author information

Authors and Affiliations

Corresponding author

Additional information

Text © The Author(s), 2019, published in Zhurnal Strukturnoi Khimii, 2019, Vol. 60, No. 5, pp. 864-870.

Rights and permissions

About this article

Cite this article

Al-Hajji, L. A Comparative Study on the Zinc Metatitanate Microstructure by Ball Milling and Solvothermal Approaches. J Struct Chem 60, 830–837 (2019). https://doi.org/10.1134/S0022476619050172

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0022476619050172