Abstract

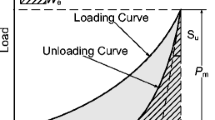

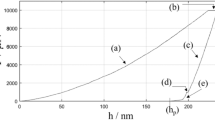

The elastic compliance of the instrument (hardness tester) should be taken into account when determining the mechanical properties of materials by means of instrumented indentation with registration of indentation diagrams. The values of Young’s modulus of the tested materials significantly depend on the method for evaluating and accounting for elastic compliance. Therefore, the methods should be verified during instrumented indentation of materials with known but very different Young’s moduli. Successful experience in evaluating and accounting for elastic compliance of the instrument during the instrumented indentation of materials with a diamond pyramid has already been accumulated to date. This is reflected in the relevant standards. However, this experience cannot be applied to instrumented indentation with a steel ball or hard-metal ball without additional research and experimental verification. We propose a method for evaluating the elastic compliance of the hardness tester using the instrumented diagram of ball indentation based on the Hertz equation in the case of elastic contact of the ball with the plane. It is found that additional elastic deformations of the links of instrument are directly proportional to the indentation load; this dependence is typical of each instrument and the diameter of the ball does not affect it. This dependence allows one to take into account the elastic compliance of the instrument using software when registering and processing diagrams of ball indentation. Experiments to determine Young’s modulus and hardness by instrumented ball indentation of various materials (steel, aluminum alloy, magnesium alloy, and titanium alloy) using the known and proposed methods to account for the elastic compliance of the instrument are performed. The main criterion confirming the reliability of the method is the coincidence or proximity of the values of Young’s modulus of the same material determined from the diagram of ball indentation and the diagram of tension of the sample. The advantages and disadvantages of the known and proposed methods are described. Practical recommendations for use of these methods are given.

Similar content being viewed by others

REFERENCES

Bulychev, S.I., Alekhin, V.P., and Ternovskii, A.P., Evaluation of materials mechanical properties using instrumented indentation, Fiz. Khim. Obrab. Mater., 1976, no. 2, pp. 54–58.

Bulychev, S.I. and Alekhin, V.P., Ispytanie materialov nepreryvnym vdavlivaniem indentora (Materials Instrumented Indentation Test), Moscow: Mashinostroenie, 1990.

Fedosov, S.A. and Peshek, L., Opredelenie mekhanicheskikh svoistv materialov mikroindetirovaniem. Sovremennye zarubezhnye metodiki (The Application of Microindentation Methods for Materials Mechanical Properties Evaluation: Modern Foreign Methods), Moscow: Mosk. Gos. Univ., 2004.

Oliver, W.C. and Pharr, G.M., An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments, J. Mater. Res., 1992, vol. 7, no. 6, pp. 1564–1583.

Oliver, W.C. and Pharr, G.M., Measurement of hardness and elastic modulus by instrumented indentation: advances in understanding and refinements to methodology, J. Mater. Res., 2004, vol. 19, no. 1, pp. 3–20.

Golovin, Yu.I., Nanoindetirovanie i ego vozmozhnosti (Nanoindentation and Its Potential), Moscow: Mashinostroenie, 2009.

Matyunin, V.M., Indetirovanie v diagnostike mekhanicheskikh svoistv materialov (Use of Indentation for Diagnostics of Mechanical Properties of the Materials), Moscow: Mosk. Energ. Inst., 2015.

Drozd, M.S., Matlin, M.M., and Sidyakin, Yu.I., Inzhenernye raschety uprugoplasticheskoi kontaktnoi deformatsii (Engineering Calculations for Elastoplastic Contact Strain), Moscow: Mashinostroenie, 1986.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Additional information

Translated by I. Obrezanova

Rights and permissions

About this article

Cite this article

Matyunin, V.M., Marchenkov, A.Y., Abusaif, N. et al. Evaluation of the Elastic Compliance of the Hardness Tester in Instrumented Indentation Tests. Inorg Mater 56, 1492–1498 (2020). https://doi.org/10.1134/S0020168520150157

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0020168520150157