Abstract

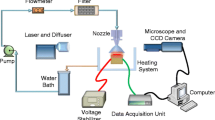

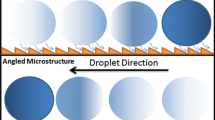

In this study the effects of nano/microstructuring and surface chemistry on wettability, evaporation rate and the Leidenfrost temperature are experimentally investigated. The functional surfaces with two alternative patterns were originally fabricated via direct femtosecond laser surface processing of polished silicon wafer in air at a fluence slightly above ablation threshold. The droplet lifetime method was used to measure the evaporation rate of a water droplet (4.5 μL) at surface temperatures of 25–350°C and to determine the Leidenfrost temperature. Generally, after processing the functional surfaces with hierarchical surface morphology demonstrate enhanced wetting behavior, evaporation rate enhancement and positive shifts in the Leidenfrost temperature. The functional surfaces with a microgrooved surface pattern, extensively covered by flake-like nanostructures, exhibit strong superhydrophilicity, resulted in a significant temperature-dependent enhancement of evaporation rate (up to 6 times) and an increase of about 30°C in the Leidenfrost temperature relative to the polished surface. The functional surfaces with a microcratered surface pattern being only hydrophilic demonstrate a nearly twofold temperature-independent enhancement of evaporation rate. Thermostability tests showed the heating of the functional surfaces above 340°C to be resulted in a drastically deteriorated wettability and a reduction of evaporative heat transfer performance under repeated experiments.

Similar content being viewed by others

References

Kruse, C., Anderson, T., Wilson, C., Zuhlke, C., Alexander, D., Gogos, G., and Ndao, S., Int. J. Heat Mass Transfer 2014, vol. 82, p. 109.

Kruse, C., Anderson, T., Wilson, C., Zuhlke, C., Alexander, D., Gogos, G., and Ndao, S., Langmuir 2013, vol. 29, p. 9798.

Frysali, M.A., Papoutsakis, L., Kenanakis, G., and Anastasiadis, S.H., J. Phys. Chem. C, 2015, vol. 119, no. 45, p. 25401.

Stratakis, E., Mateescu, A., Barberoglou, M., Vamvakaki, M., Fotakis, C., and Anastasiadis, S.H., Chem. Commun. 2010, vol. 46, p. 4136.

Zhang, X., Liu, H., Huang, X., and Jiang, H., J. Mater. Chem. C, 2015, vol. 3, p. 3336.

Matsuda, T., Sano, T., Arakawa, K., and Hirose, A., Appl. Phys. Lett. 2014, vol. 105, 021902.

Matsuda, T., Sano, T., Arakawa, K., and Hirose, A., J. Appl. Phys., 2014, vol. 116, 183506.

Vorobyev, A. and Guo, C., Laser Photonics Rev. 2013, vol. 7, no. 3, p. 385.

Rodriguez, R. and Redman, R., J. Exp. Bot., 2008, vol. 59, no. 5, p. 1109.

Otten, A. and Herminghaus, S., Langmuir 2004, vol. 20, p. 2405.

Neinhuis, C. and Barthlott, W., Ann. Bot. (Oxford, U.K.) 1997, vol. 79, no. 6, p. 667.

Vorobyev, A. and Guo, C., J. Appl. Phys., 2015, vol. 117, 033103.

Vorobyev, A.Y. and Guo, C., Opt. Express 2010, vol. 18, no. 7, p. 6456.

Zorba, V., Persano, L., Pisignano, D., Athanassiou, A., Stratakis, E., Cingolani, R., Tzanetakis, P., and Fotakis, C., Nanotecnology 2006, vol. 17, p. 3234.

Paradisanos, I., Fotakis, C., Anastasiadis, S.H., and Stratakis, E., Appl. Phys. Lett. 2015, vol. 107, 111603.

Baldacchini, T., Carey, J.E., Zhou, M., and Mazur, E., Langmuir 2006, vol. 22, no. 11, p. 4917.

Barberoglou, M., Zorba, V., Stratakis, E., Spanakis, E., Tzanetakis, P., Anastasiadis, S.H., and Fotakis, C., Appl. Surf. Sci. 2009, vol. 255, p. 5425.

Cottin-Bizonne, C., Barrat, J.L., Bocquet, L., and Charlaix, E., Nat. Mater. 2003, vol. 2, p. 237.

Koch, K., Bhushan, B., and Barthlott, W., Prog. Mater. Sci. 2009, vol. 54, p. 137.

Genzer, J. and Efimenko, K., Biofouling 2006, vol. 22, p. 339.

Gholaminejad, A. and Hosseini, R., J. Electron. Cool. Therm. Control, 2013, vol. 3, p. 1.

Celia, E., Darmanin, T., Taffin de Givenchy, E., Amigoni, S., and Guittard, F., J. Colloid Interface Sci. 2013, vol. 402, p. 1.

Xi, J., Feng, L., and Jiang, L., Appl. Phys. Lett. 2008, vol. 92, 053102.

Gottfried, B.S., Lee, C.J., and Bell, K.J., Int. J. Heat Mass Transfer 1966, vol. 9, p. 1167.

Romashevskiy, S.A., Agranat, M.B., and Dmitriev, A.S., High Temp. 2016, vol. 54, no. 3, p. 461.

Quéré, D., Annu. Rev. Fluid Mech. 2013, vol. 45, p. 197.

Liu, G. and Craig, V.S., Faraday Discuss. 2010, vol. 146, p. 141.

Bernardin, J.D. and Mudawar, I., Int. J. Heat Mass Transfer 1997, vol. 40, p. 2579.

Author information

Authors and Affiliations

Corresponding author

Additional information

The article is published in the original.

Rights and permissions

About this article

Cite this article

Romashevskiy, S.A., Ovchinnikov, A.V. Functional Surfaces with Enhanced Heat Transfer for Spray Cooling Technology. High Temp 56, 255–262 (2018). https://doi.org/10.1134/S0018151X18020244

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0018151X18020244