Abstract

This paper provides empirical evidence on the impact of digitalisation on product upgrading in Global Value Chains (GVCs). Analysis is done for a sample of Indian manufacturing GVC firms in the period 2001–2015 from the firm-level database Prowess, using the methodology of System Generalised Method of Moments. Product upgrading is captured by a novel sales-weighted average product sophistication indicator constructed at the firm level. Digitalisation is captured through a digital capability index, constructed using principal component analysis, which draws information on both ‘hard’ and ‘soft’ digital assets for firms. Empirical results indicate that an increase in digital capability of an Indian GVC firm has a significant and positive impact on its product sophistication, implying that by investing in digital capabilities, Indian manufacturing firms can produce better and more sophisticated products in GVCs, enabling them to upgrade and climb up the value-chain ladder. Firms that are Digital Leaders produce 4–5% more sophisticated goods than Digital Laggards.

Résumé

Cet article fournit des preuves empiriques de l'impact de la numérisation sur la modernisation des produits dans les chaînes de valeur mondiales (CVM). L'analyse est effectuée sur un échantillon de manufactures indiennes dans la CVM au cours de la période 2001-2015 à partir de la base de données d'entreprise Prowess, en utilisant la méthode des moments généralisés par système. La modernisation des produits est mesurée grâce à un nouvel indicateur de sophistication moyenne des produits pondéré par les ventes au niveau de l'entreprise. La numérisation est mesurée au moyen d'un indice de capacité numérique, construit à l'aide de l'analyse des composants principaux, qui tire des informations sur les actifs numériques à la fois «matériels» et «logiciels» des entreprises. Les résultats empiriques indiquent qu'une augmentation de la capacité numérique d'une entreprise indienne dans la CVM a un impact significatif et positif sur la sophistication de ses produits, ce qui implique qu'en investissant dans les capacités numériques, les manufactures indiennes peuvent produire des produits meilleurs et plus sophistiqués dans la CVM, ce qui leur permet de se moderniser et de gravir l’échelle de la chaîne de valeur. Les entreprises qui sont des leaders numériques produisent 4% à 5% de produits plus sophistiqués que les celles qui sont des retardataires en matière de numériques.

Similar content being viewed by others

Notes

Prowess reports on total exports of the firm; it does not distinguish between intermediate and final exports.

Products that score high on prody sophistication indicator are also observed to have a high value (greater than 1) on the product complexity indicator, developed by Hidalgo and Hausmann (2009).

Using GDP per capita PPP allows for correction of differences across time (inflation) and across countries (deviations from PPP). This means that the product sophistication indicators can be compared across time and countries.

Since the exporting countries and comparative advantages can change over time, calculating product sophistication using different countries in different years can create biases in the indicator (Hausmann et al. 2007). Therefore, it is important to create sophistication indices using data from a consistent sample of countries that report trade data in the period 2001–2015. This means exclusion of those countries for which trade data are missing for even one period in 2001–15. Consistent data are obtained for 113 countries, reporting both export flows and GDP in the period considered.

Developed by Pearson (1901), PCA is a statistical technique to reduce dimensionality of multivariate data, widely used in literatures from many disciplines (Jolliffe and Cadima 2016). To construct the digital capability index, Kaiser’s rule—retaining components with eigenvector greater than 1—is followed and component 1 is chosen, which explains about 56 per cent of variation in the variables. Weights obtained from component 1 (0.55 for software assets, 0.65 for communication and transport infrastructure assets, and 0.54 for technology assets) are then used to construct the weighted digital capability index for every firm.

This option subtracts the average of all available future observations, rather than subtracting the previous observation from the current one.

Prowess data do not allow one to analyse entry and exit. However, data in Prowess mostly come from medium to large firms, therefore missing data for a firm is most likely due to the fact that the firm has not reported the data rather than it has exited the industry. The paper uses an unbalanced panel in which sample size varies from year to year, with only data availability and purging of outliers guiding our sample selection.

It is interesting to note that these firm categories are closely related to Gereffi et al.’s (2005) GVC governance categories based on three key indicators: complexity of transactions, codifiability of information, and supplier competence. When information is complex and codifiability is low, suppliers will require a more skilled workforce to de-codify transactions (Lakhani et al.’s 2013), indicating an inverse relation between share of skilled labour and codifiability. Supplier competence—the ability of the supplier to interact with foreign buyers, to receive orders, and to fulfil requirements—is likely to be positively correlated with the digital capability index. From the governance perspective, the results in Table 6 therefore indicate that Indian firms linked in captive-type GVC governance structures (suppliers with overall low digital competence) are producing significantly less-sophisticated goods than relational suppliers (suppliers with high digital competence).

References

Andrews, D., C. Criscuolo, and P. Gal. 2016. The Global Productivity Slowdown, Technology Divergence and Public Policy: A Firm Level Perspective. Background Paper for OECD Global Forum on Productivity. Paris: OECD.

Arellano, M., and O. Bover. 1995. Another Look at the Instrumental Variable Estimation of Error-Components Models. Journal of Econometrics 68 (1): 29–51.

Arnold, J.M., and B.S. Javorcik. 2009. Gifted Kids or Pushy Parents? Foreign Direct Investment and Plant Productivity in Indonesia. Journal of International Economics 79 (1): 42–53.

Atasoy, B.S. 2020. The Determinants of Export Sophistication: Does Digitalization Matter? International Journal of Finance & Economics. https://doi.org/10.1002/ijfe.2058.

Baldwin, J.R., and B. Yan. 2014. Global Value Chains and the Productivity of Canadian Manufacturing Firms. Economic Analysis Research Paper 90. Ottawa: Statistics Canada.

Banga, K. 2016. Impact of Global Value Chains on Employment in India. Journal of Economic Integration 31 (3): 631–673.

Banga, K. 2017. Global Value Chains and Product Sophistication: An Empirical Investigation of Indian Firms. Working Paper 2017–15. Geneva: CETI.

Banga, K., and D.W. te Velde. 2018. How to Grow Manufacturing and Create Jobs in a Digital Economy: 10 Policy Priorities in Kenya. Report. London: Overseas Development Institute.

Banga, K., and D.W. te Velde. 2018b. Skill Needs for the Future. Background Paper 10. Oxford: Pathways for Prosperity Commission.

Banga, R. 2019. Is India Digitally Prepared for International Trade? Economic and Political Weekly, 54(5).

Barrows, G., and H. Ollivier. 2016. Emission Intensity and Firm Dynamics: Reallocation, Product Mix, and Technology in India. Working Paper 245. London: London School of Economics.

Bas, M., and V. Strauss-Kahn. 2015. Input-Trade Liberalization, Export Prices and Quality Upgrading. Journal of International Economics 95 (2): 250–262.

Bell, M., and M. Albu. 1999. Knowledge Systems and Technological Dynamism in Industrial Clusters in Developing Countries. World Development 27 (9): 1715–1734.

Bell, M., and K. Pavitt. 1993. Accumulating Technological Capability in Developing Countries. In Proceedings of the World Bank Annual Conference on Development Economics. Washington, DC: World Bank.

Cattaneo, O., G. Gereffi, S. Miroudot, and D. Taglioni. 2013. Joining, upgrading and being competitive in global value chains: A strategic framework. Washington, DC: The World Bank.

Córcoles, D., C. Díaz-Mora, and R. Gandoy. 2014. Product Sophistication: A Tie that Binds Partners in International Trade. Economic Modelling 44 (S1): 33–41.

Dachs, B., S. Kinkel, and A. Jäger. 2017. Bringing It All Back Home? Backshoring of Manufacturing Activities and the Adoption of Industry 4.0 Technologies. MPRA Paper 83167. Munich: Munich Personal RePEc Archive.

Dauth, W., S. Findeisen, and J. Suedekum. 2017. Trade and Manufacturing Jobs in Germany. American Economic Review 107 (5): 337–342.

De Backer, K., and D. Flaig. 2017. ‘The Future of Global Value Chains Business as Usual or “a New Normal”?’ OECD Science, Technology and Industry Policy Papers 41. Paris: OECD Publishing.

Dicken, P., P.F. Kelly, K. Olds, and H. Wai-Chung Yeung. 2001. Chains and Networks, Territories and Scales: Towards a Relational Framework for Analysing the Global Economy. Global Networks 1 (2): 89–112.

Eck, K., and S. Huber. 2016. Product Sophistication and Spillovers from Foreign Direct Investment. Canadian Journal of Economics 49 (4): 1658–1684.

Figueiredo, P.N. 2001. Technological Learning and Competitive Performance. Cheltenham: Edward Elgar.

Foster, C., M. Graham, L. Mann, T. Waema, and N. Friederici. 2018. Digital Control in Value Chains: Challenges of Connectivity for East African Firms. Economic Geography 94 (1): 68–86.

Gereffi, G., J. Humphrey, and T. Sturgeon. 2005. The Governance of Global Value Chains. Review of International Political Economy 12 (1): 78–104.

Giuliani, E., and M. Bell. 2005. The Micro-Determinants of Meso-Level Learning and Innovation: Evidence from a Chilean Wine Cluster. Research Policy 34 (1): 47–68.

Goldar, B., D.K. Das, S. Sengupta, and P. Das. 2017. Domestic Value Addition and Foreign Content: An Analysis of India’s Exports from 1995 to 2011. Working Paper 332. New Delhi: Indian Council for Research on International Economic Relations.

Goldar, B., R. Banga, and K. Banga. 2018. India’s Linkages into Global Value Chains: The Role of Imported Services. In Indian Policy Forum 2017. New Delhi: NCAER.

Graetz, G., and G. Michaels. 2017. Is Modern Technology Responsible for Jobless Recoveries? American Economic Review 107 (5): 168–173.

Guadalupe, M., O. Kuzmina, and C. Thomas. 2012. Innovation and Foreign Ownership. American Economic Review 102 (7): 3594–3627.

Harding, T., and B.S. Javorcik. 2012. Foreign Direct Investment and Export Upgrading. Review of Economics and Statistics 94 (4): 964–980.

Hausmann, R. and B. Klinger. 2006. Structural Transformation and Patterns of 23 Comparative Advantage in the Product Space. Center for International Development Working Paper, No. 128, Cambridge, MA: Harvard University

Hausmann, R., J. Hwang, and D. Rodrik. 2007. What You Export Matters. Journal of Economic Growth 12 (1): 1–25.

Hidalgo, C.A., and R. Hausmann. 2009. The Building Blocks of Economic Complexity. Proceedings of the national academy of sciences 106 (26): 10570–10575.

Horner, R., and K. Nadvi. 2018. Global Value Chains and the Rise of the Global South: Unpacking Twenty-First Century Polycentric Trade. Global Networks 18 (2): 207–237.

Huber, S. 2017. Indicators of Product Sophistication and Factor Intensities: Measurement Matters. Journal of Economic and Social Measurement 42 (1): 27–65.

ITC. 2018. What Sells in E-Commerce: New Evidence from Asian LDCs. Geneva: International Trade Centre.

Jarreau, J., and S. Poncet. 2012. Export Sophistication and Economic Growth: Evidence from China. Journal of development Economics 97 (2): 281–292.

Javorcik, B.S., A. Lo Turco, and D. Maggioni. 2017. New and Improved: Does FDI Boost Production Complexity in Host Countries? The Economic Journal. https://doi.org/10.1111/ecoj.12530.

Jolliffe, I.T. 2002. Principal Component Analysis, 2nd ed. New York: Springer.

Jolliffe, I.T., and J. Cadima. 2016. Principal Component Analysis: A Review and Recent Developments. Philosophical Transactions of the Royal Society A 374 (2065): 20150202.

Kaplinsky, R., and M. Morris. 2000. A Handbook for Value Chain Research. Brighton: University of Sussex, Institute of Development Studies.

Khandelwal, A. 2010. The Long and Short (of) Quality Ladders. The Review of Economic Studies 77 (4): 1450–1476.

Khandelwal, A.K., P.K. Schott, and S.J. Wei. 2013. Trade Liberalization and Embedded Institutional Reform: Evidence from Chinese Exporters. American Economic Review 103 (6): 2169–2195.

Kočenda, E., and K. Poghosyan. 2018. Export Sophistication: A Dynamic Panel Data Approach. Emerging Markets Finance and Trade 54 (12): 2799–2814.

Kroll, H., D. Horvat, and A. Jäger. 2018. Effects of Automatisation and Digitalisation on Manufacturing Companies’ Production Efficiency and Innovation Performance. Innovation Systems and Policy Analysis Discussion Paper 58. Karlsruhe: Fraunhofer ISI.

Lakhani, T., S. Kuruvilla, and A. Avgar. 2013. From the Firm to the Network: Global Value Chains and Employment Relations Theory. British Journal of Industrial Relations 51 (3): 440–472.

Lall, S. 2001. Competitiveness, Technology and Skills. Cheltenham: Edward Elgar.

Manova, K., and Z. Zhang. 2012. Export Prices Across Firms and Destinations. The Quarterly Journal of Economics 127 (1): 379–436.

Mason, G. 2005. In Search of High Value Added Production: How Important are Skills? London: Department for Education and Skills.

Mayer, J. 2018. Digitalization and Industrialization: Friends or Foes? Research Paper 25. Geneva: UNCTAD.

Milberg, W., and D. Winkler. 2013. Outsourcing Economics: Global Value Chains in Capitalist Development. Cambridge: Cambridge University Press.

Morrison, A., C. Pietrobelli, and R. Rabellotti. 2008. Global Value Chains and Technological Capabilities: A Framework to Study Learning and Innovation in Developing Countries. Oxford Development Studies 36 (1): 39–58.

Pearson, K. 1901. Principal Component Analysis. The London Edinburgh and Dublin Philosophical Magazine and Journal of Science 6 (2): 559.

Pietrobelli, C., and R. Rabellotti. 2008. The Global Dimension of Innovation Systems and Enterprise Upgrading: Linking Innovation Systems and Global Value Chains. In Handbook of Innovation Systems and Developing Countries: Building Domestic Capabilities in a Global Setting, ed. B.A. Lundvall, K.J. Joseph, C. Chaminade, and J. Vang. Cheltenham: Edward Elgar.

Pietrobelli, C., and R. Rabellotti. 2011. Global Value Chains Meet Innovation Systems: Are There Learning Opportunities for Developing Countries? World Development 39 (7): 1261–1269.

Ponte, S., and J. Ewert. 2009. Which Way is “Up” in Upgrading? Trajectories of Change in the Value Chain for South African Wine. World Development 37 (10): 1637–1650. https://doi.org/10.1016/j.worlddev.2009.03.008.

Puga, D., and D. Trefler. 2010. Wake Up and Smell the Ginseng: International Trade and the Rise of Incremental Innovation in Low-Wage Countries. Journal of Development Economics 91 (1): 64–76.

Ray, S., and S. Miglani. 2018. Global Value Chains and the Missing Links: Cases from Indian Industry. New Delhi: Routledge India.

Rodrik, D. 2018. New Technologies, Global Value Chains, and Developing Economies. Working Paper 25164. Cambridge, MA: National Bureau of Economic Research.

Roodman, D. 2009. How to do xtabond2: An Introduction to Difference and System GMM in Stata. Stata Journal 9 (1): 86–136.

Szalavetz, A. 2019. Digitalisation, Automation and Upgrading in Global Value Chains: Factory Economy Actors Versus Lead Companies. Post-Communist Economies.

Tucci, A. 2005. Trade, Foreign Networks and Performance: A Firm-Level Analysis for India. Development Studies Working Paper 199. Torino: Centro Studi Luca d’Agliano.

Veugelers, R., F. Barbiero, and M. Blanga-Gubbay. 2013. Meeting the Manufacturing Firms Involved in GVCs. In Manufacturing Europe’s Future, ed. R. Veugelers. Bruegel: Brusselys.

World Bank. 2019. World Development Report 2020: Trading for Development in the Age of Global Value Chains. World Bank: Washington D.C.

Acknowledgements

This study was originally published under the UNU-WIDER project “Structural transformation—old and new paths to economic development.” The author extends thanks to Christopher Foster, Jostein Hauge and participants at the UNIDO and SASE workshops for feedback and comments.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendices

Appendix 1: Matching procedure

Each product in Prowess is defined by a unique 14-digit product code (PRID). Following Barrows and Ollivier (2016), each PRID is standardised to a product name by considering the number of times a product name is reported for a particular code and the product names reported for the PRID code at a more disaggregated level. The data are then cleaned, whereby all the products that are not classified under the manufacturing sector in Prowess data are removed. This involves removing products classified by Prowess as animal products, agricultural products, services, construction, and irrigation. After data cleaning, 2,977 unique 14-digit product codes are obtained. These product codes are then matched to the HS four-digit classification from WITS, using product names and numerical ordering. Both classifications have similar names and ordering, allowing 80% of the products in Prowess to be matched with four-digit HS classification (HS 1996). For example, in Prowess the PRID 6070101000000 refers to ‘Men’s overcoats etc., knitted or crocheted’, followed by the PRID 6070102000000—‘Women’s overcoats, knitted or crocheted’. These names are very easily matched to HS code 6101 ‘Men’s or boys’ overcoats, car-coats, etc. knitted or crocheted’ and HS 6102 ‘Women’s or girls’ overcoats, car-coats, knitted or crocheted’, respectively. See Banga (2017) for more details on matching.

Appendix 2

See Table 1.

Appendix 3

See Table 2.

Appendix 4

See Table 3.

Appendix 5

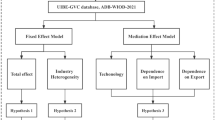

See Fig. 1.

Appendix 6

See Table 4.

Appendix 7

See Table 5.

Appendix 8

See Table 6.

Rights and permissions

About this article

Cite this article

Banga, K. Digital Technologies and Product Upgrading in Global Value Chains: Empirical Evidence from Indian Manufacturing Firms. Eur J Dev Res 34, 77–102 (2022). https://doi.org/10.1057/s41287-020-00357-x

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1057/s41287-020-00357-x