Abstract

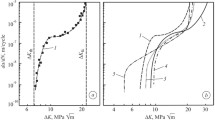

We analyze fatigue-crack growth rate diagrams for various modifications of a Ti–Si cermet alloy in the initial (as-cast) state and after thermomechanical treatment plotted for beam specimens subjected to three-point bending. It is shown that, for different asymmetries of the loading cycle, the maximum stress intensity factor K max better describes the behavior of the growth rate of fatigue macrocracks in the high-amplitude part of the diagrams than the range of the stress intensity factor ΔK. The threshold crack resistance of the Ti–Si composite under cyclic loading is 2–5 times lower than under long-term static loading. For highly asymmetric loading cycles (R = 0.6), the maximum cyclic crack-growth resistance is exhibited by a modification with the structure of grains of pseudo-α-titanium matrix 20–40 μm in size and 15–30 wt.% of dispersed precipitations of titanium and intermetallic silicides 5–10 μm in size.

Similar content being viewed by others

REFERENCES

V. I. Mazur, Y. N. Taran, and S. V. Kapustnikova, Titanium Matrix Composites, U.S. Patent, No. 5 366 570, 22/11 (1994).

O. N. Romaniv, S. Ya. Yarema, G. N. Nikiforchin, et al., “Fatigue and cyclic crack resistance of structural materials,” in: V. V. Panasyuk (editor), Fracture Mechanics and Strength of Materials [in Russian], Vol. 4, Naukova Dumka, Kiev (1990).

M. S. Miller and J. P. Gallagher, “An analysis of several fatigue crack growth rate descriptions,” in: Fatigue Crack Growth Measurement and Data Analysis, ASTM STP 738, Philadelphia (Pa) (1981), pp. 205–251.

O. P. Ostash, V. T. Zhmur-Klimenko, E. M. Kostyk, and A. B. Kunovskii, “Effect of crack closure and the asymmetry of loading cycles on the kinetic diagrams of fatigue fracture at normal and low temperatures,” Fiz.-Khim. Mekh. Mater., 23, No. 3, 58–63 (1987).

O. P. Ostash, E. M. Kostyk, and I. N. Levina, “Influence of low temperature on the initiation and growth of fatigue cracks in 03kp steel with different grain sizes,” Fiz.-Khim. Mekh. Mater., 24, No. 4, 63–71 (1988).

R. O. Ritchie, “Small crack growth and the fatigue of traditional and advanced materials,” in: Proc. of the 7th Internat. Fatigue Congress (Fatigue' 99) (Beijing, June 1999),Vol. 1, Higher Education Press, EMAS (1999), pp. 3–13.

Y. Mutoh, M. Takanashi, and M. Takeuchi, “Fatigue crack growth in several ceramic materials,” Fatigue Fract. Eng. Mater. Struct., 16, No. 8, 875–890 (1993).

Y.-H. Huh and J.-H. Song, “Cyclic fatigue crack growth and closure behavior in alumina ceramics,” Fatigue Fract. Eng. Mater. Struct., 21, 1575–1587 (1998).

B. D. Vasyliv, Structural Optimization of Ceramic Materials Based on the Parameters of Crack Resistance [in Ukrainian], Author's Abstract of the Candidate Degree Thesis (Engineering), Lviv (1998).

O. N. Romaniv and G. N. Nikiforchin, Mechanics of Corrosion Fracture of Structural Alloys [in Russian], Metallurgiya, Moscow (1986).

Rights and permissions

About this article

Cite this article

Ostash, O.P., Ivasyshyn, A.D., Vasyliv, B.D. et al. Influence of the Structure and Asymmetry of Loading Cycles on the Cyclic Crack Resistance of Ti–Si Composites. Materials Science 38, 55–61 (2002). https://doi.org/10.1023/A:1020120714703

Issue Date:

DOI: https://doi.org/10.1023/A:1020120714703