Abstract

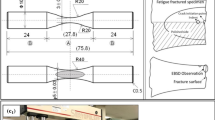

The tensile and fatigue behaviour of ingot metallurgy beryllium/aluminium alloys produced by Nuclear Metals, Inc., is determined as a function of temperature. The wrought alloy and the casting alloy are both shown to have a very high stiffness to density ratio compared with common structural materials. The wrought alloy was found to have superior fatigue strength, tensile strength and ductility relative to the casting alloy; it also maintained a greater fraction of its tensile strength as a function of temperature. The stiffness of the materials can be readily explained using standard composite theory, where the material is treated as a discontinuous beryllium-reinforced aluminium matrix composite. The strength of the casting alloy is controlled to a large extent by the strength of its aluminium alloy matrix. In contrast, strengthening increments from both dislocation-based mechanisms and load transfer appear to be operative for the wrought material. Fractographic analysis of tensile specimens showed that preferential failure of the aluminium regions or the beryllium/aluminium interfacial regions occurs under certain circumstances. Fracture analysis of fatigue samples revealed no obvious fracture initiation sites and no evidence of limited/controlled crack growth regions.

Similar content being viewed by others

References

W. T. NACHTRAB, K. R. RAFTERY and T. D. SANBORN, in “Proceedings of the 3rd Near Net Shape Manufacturing Conference”, P. W. Lee and B. L. Ferguson (ASM International, Pittsburgh, PA, 1993) pp. 27–32.

V. C. NARDONE and T. J. GAROSSHEN, J. Mater. Sci., submitted.

J. C. HALPIN, “Primer on Composite Materials: Analysis” (Technomic Publishing, Lancaster, PA, 1984) pp. 130–8.

R. F. WILDE and N. J. GRANT, “Dynamic Elastic Modulus Values at High Temperatures for Nickel-Base, Aluminium-Base and Metal-Metal Oxide Alloys”, ASTM Proceedings, Vol. 57 (American Society for Testing and Materials, Philadelphia, PA, 1957) pp. 917–28.

“Designing with Beryllium” (Brush Wellman Inc., Cleveland, OH).

R. A. MAYOR, J. R. STRIFE and V. C. NARDONE, “Metal Matrix Composites Structural Data Development”, AFWAL TR 86–4129 (1987).

“Metals Handbook”, 9th Edn, Vol. 2, “Properties and Selection: Nonferrous Alloys and Pure Metals” (American Society for Metals, Metals Park, OH, 1979) pp. 159–60.

A. M. REDSTEN, E. M. KLIER, A. M. BROWN and D. C. DUNAND, Mater. Sci. Eng. A201 (1995) 88.

M. F. ASHBY and A. S. ARGON (eds), “Physics of Strength and Plasticity” (Massachusetts Institute of Technology Press, Cambridge, MA, 1969) p. 113.

D. C. DUNAND and A. MORTENSEN, Acta Metall. Mater. 39 (1991) 127.

P. M. HAZZLEDINE, Scripta Metall. Mater. 26 (1992) 57.

V. C. NARDONE and K. M. PREWO, ibid. 20 (1986) 43.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Nardone, V.C., Garosshen, T.J. Evaluation of the tensile and fatigue behaviour of ingot metallurgy beryllium/aluminium alloys. Journal of Materials Science 32, 3975–3985 (1997). https://doi.org/10.1023/A:1018677102160

Published:

Issue Date:

DOI: https://doi.org/10.1023/A:1018677102160