Abstract

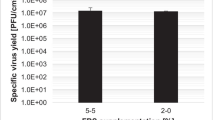

To indentify a plausible large-scale production system forretroviral vector, three culture systems, i.e., batch culturewith medium exchange, microcarrier culture, and packed-bedreactor culture were compared. In batch cultures with mediumexchange, high cell concentrations were maintained for about amonth, and the harvested retroviral titer remained constant. Inmicrocarrier cultures, although cell growth was rapid, theretroviral titer was unexpectedly low, suggesting that the lowtiter was due either to serious damage to the retroviral vectoror to a reduction in the production rate of retroviral vector,caused by mechanical shear forces. Although the retroviral titer(maximum titer, 1.56 × 106) in the packed-bedreactor was a little bit lower than that obtained in the batchculture with medium exchange (maximum titer, 1.91 ×106), continuous production made it possible to increasethe cumulative titer up to 16-fold of that from the batchculture with medium exchange. Moreover, as the packed-bedreactor system requires less labor and shows excellentvolumetric productivity in comparison to batch cultures withmedium exchanges, it will be an appropriate production systemfor retroviral vector in large quantities.

Similar content being viewed by others

References

Andreadis ST, Roth CM, Le Doux JM, Morgan JR and Yarmush ML (1999) Large-scale processing of recombinant retroviruses for gene therapy. Biotechnol Prog 15: 1–11.

Chiou TW, Murakami S and Wang DIC (1991) A fiber-bed bioreactor for anchorage-dependent animal cell culture: Part I. Bioreactor design and operations. Biotechnol Bioeng 37: 755–761.

Chuck AC and Palsson BO (1996) Consistent and high rate of gene transfer can be obtained using flow-through transduction over a wide range of retroviral titers. Hum Gene Ther 7: 743–750.

Croughan MS, Hamel JF and Wang DIC (1987) Hydrodynamic effects on animal cells grown in microcarrier cultures. Biotechnol Bioeng 29: 130–141.

Dranoff G, Jaffee EM, Golumbeck, P, Levitsky H, Bros K, Jackson V, Hamada H, Pardoll DM and Mulligan RC (1993) Vaccination with irradiated tumor cells engineerd to secrete murine GMCSF stimulates potent, specific and long lasting antitumor immunity. Proc Natl Acad Sci USA 90: 3539–3543.

Griffiths B and Looby D (1991) Fixed Immobilized Beds for the Cultivation of Animal Cells. In: Chester SH and Wang DIC (eds) Animal Cell Bioreactors, pp. 165–189. Butterworth-Heinemann, MA.

Hu WS, Meier J and Wang DIC (1985) A mechanistic analysis of the inoculum requirement for the cultivation of mammalian cells on microcarriers. Biotechnol Bioeng 27: 585–595.

Hu WS and Peshwa MV (1991) Animal cell bioreactor-Recent advances and challenges to scale-up. Canadian J Chem Eng 69: 409–420.

Jolly D (1994) Viral vector systems for gene therapy. Cancer Gene Therapy 1: 51–64.

Kaltenbach JP, Kaltenbach MH and Lyons WB (1958) Nigrosin as a dye for differentiating live and dead ascites cells. Exp Cell Res 15: 112–117.

Le Doux JM, Davis HE, Morgan JR and Yarnush ML (1999) Kinetics of retrovirus production and decay. Biotechnol Bioeng 63: 654–662.

Lee GM, Choi JH, Jun SC and Palsson BO (1998) Temperature significantly affects retroviral vector production and deactivation rates, and thereby determines retroviral titers. Bioprocess Engineering 19: 343–349.

Lee SG, Kim S, Robbins PD and Kim BG (1996) Optimization of environmental factors for the production and handling of recombinant retrovirus. Appl Microbiol Biotechnol 45: 477–483.

Looby D and Griffiths B (1988) Fixed bed porous glass spheres (porous sphere) bioreactors for animal cells. Cytotechnology 1: 339–346.

Miller, AD (1992) Human gene therapy comes of age. Nature 357 (6378): 455–460.

Oh DJ, Choi SK and Chang HN (1994) High-density continuous cultures of hybridoma cells in a depth filter system. Biotechnol Bioeng 44: 896–901.

Ohashi T, Boggs S and Robbins P (1992) Efficient transfer and sustained high expression to the human glucocerebrosidase gene in mice and their functional macrophages following translation of bone marrow transduced by a retroviral vector. Proc Natl Acad Sci USA 89: 11332–11336.

Ory DS, Neugeboren BA and Mulligan RC (1996) A stable humanderived packaging cell line for production of high titer retrovirus/ vesicular stomatitis virus G pseudotypes. Proc Natl Acad Sci USA 93: 11400–11406.

Parente MK and Wolfe JH (1996) Production of increased titer retrovirus vectors from stable producer cell lines by superinfection and concentration. Gene Therapy 3: 756–760.

Park S and Stephanopoulos G (1993) Packed bed bioreactor with porous ceramic beads for animal cell culture. Biotechnol Bioeng 41: 25–34.

Reuveny S (1990) Microcarrier culture systems. In: Lubiniecki AS (ed.) Large-Scale Mammalian Cell Culture Technology (pp 271–341) Marcel Dekker Inc. New York.

Saines JR, Rubenstein JLR and Nicolas JF (1986) Use of a recombinant retrovirus to study postimplantation cell lineage in mouse embryos. EMBO J 5: 3133–3142.

Shen BQ, Clarke MF and Palsson BO (1996) Kinetics of retroviral production from the amphotropic9CRIP murine producer cell line. Cytotechnology 22: 185–195.

Strand JM and Quarles JM (1984) A modified matrix perfusionmicrocarrier bead cell culture system 1. Adaptation of matrix perfusion system for growth of human foreskin fibroblasts. Biotechnol Bioeng 26: 503–507.

Thilly WG (1986) Mammalian Cell Technology, pp 1–7, 91–108, 151–165. Butterworth, Stoneham, MA.

Varani J, Dame M, Beals TF and Wass JA (1983) Growth of three established cell lines on glass microcarriers. Biotechnol Bioeng 25: 1359–1372.

Widell A, Hanson B and Nordenfelt E (1984) A microcarrier cell culture system for large scale production of hepatitis A virus. J Virol Methods 8: 63–71.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Kang, SH., Kim, BG. & Lee, G.M. Justification of continuous packed-bed reactor for retroviral vector production from amphotropic ΨCRIP murine producer cell. Cytotechnology 34, 151–158 (2000). https://doi.org/10.1023/A:1008120313175

Issue Date:

DOI: https://doi.org/10.1023/A:1008120313175