Abstract

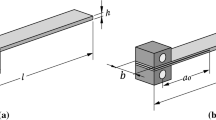

Two grades of Dyneema® composite laminates with the commercial designations of HB26 and HB50 were cut into blocks with or without an edge crack and compressed in the lon-gitudinal fiber direction. The cracked and uncracked specimens show similar compressive responses including failure pattern and failure load. The two grades of Dyneema® composites exhibits different failure modes: a diffuse, sinusoidal buckling pattern for Dyneema® HB50 due to its weak matrix constituent and a kink band for Dyneema® HB26 due to its relatively stronger matrix constituent. An effective finite element model is used to simulate the collapse of Dyneema® composites, and the sensitivity of laminate compressive responses to the overall effective shear modulus, interlaminar shear strength, thickness and imperfection angle are investigated. The change of failure mode from kink band to sinusoidal buckling pattern by decreasing the interlaminar shear strength is validated by the finite element analyses.

Similar content being viewed by others

References

B.P. Russell, K. Karthikeyan, V.S. Deshpande, N.A. Fleck, The high strain rate response of ultra high molecular-weight polyethylene: from fibre to laminate, Int. J. Impact Eng. 60 (2013) 1–9.

V.B.C. Tan, V.P.W. Shim, T.E. Tay, Experimental and numerical study of the response of flexible laminates to impact loading, Int. J. Solids Struct. 40 (2003) 6245–6266.

V.B.C. Tan, K.J.L. Khoo, Perforation of flexible laminates by projectiles of different geometry, Int. J. Impact Eng. 31 (2005) 793–810.

E.S. Greenhalgh, V.M. Bloodworth, L. Iannucci, D. Pope, Fractographic observations on Dyneema® composites under ballistic impact, Composites: Part A 44 (2013) 51–62.

K. Karthikeyan, B.P. Russell, N.A. Fleck, M. O’Masta, H.N.G. Wadley, V.S. Deshpande, The soft impact response of composite laminate beams, Int. J. Impact Eng. 60 (2013) 24–36.

K. Karthikeyan, B.P. Russell, N.A. Fleck, H.N.G. Wadley, V.S. Deshpande, The effect of shear strength on the ballistic response of laminated composite plates, Eur. J. Mech.—A/Solids 42 (2013) 35–53.

L. Iannucci, D. Pope, High velocity impact and armour design, eXPRESS Polym. Lett. 5 (2011) 262–272.

B.D.H. Utomo, L.J. Ernst, Detailed modelling of projectile impact on dyneema composite using dynamic properties, J. Solid Mech. Mater. Eng. 2 (2008) 707–717.

J.P. Attwood, S.N. Khaderi, K. Karthikeyan, N.A. Fleck, M.R. O’Masta, H.N.G. Wadley, V.S. Deshpande, The out-of-plane compressive response of Dyneema® composites, J. Mech. Phys. Solids 70 (2014) 200–226.

G. Liu, M.D. Thouless, V.S. Deshpande, N.A. Fleck, Collapse of a composite beam made from ultra high molecular-weight polyethylene fibres, J. Mech. Phys. Solids 63 (2014) 320–335.

G. Liu, Modelling microbuckling failure of a composite beam made from ultra high molecular-weight polyethylene fibres, Acta Mech. 226 (2015) 1255–1266.

M.R. O’Masta, V.S. Deshpande, H.N.G. Wadley, Defect controlled transverse compressive strength of polyethylene fiber laminates, Int. J. Solids Struct. 52 (2015) 130–149.

G. Liu, K.L. Tang, Study on stress concentration in notched cross-ply laminates under tensile loading, J. Compos. Mater. 50 (2015) 283–296.

X. Guo, R. Ji, G.J. Weng, L.L. Zhu, J. Lu, Computer simulation of strength and ductility of nanotwin-strengthened coarse-grained metals, Modell. Simul. Mater. Sci. Eng. 22 (2014) 075014-1-22.

X. Guo, R. Ji, G.J. Weng, L.L. Zhu, J. Lu, Micromechanical simulation of fracture behavior of nanostructured metal with bimodal grain size distribution, Procedia Mater. Sci. 3 (2014) 2148–2153.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, G., Zhu, W. & Huang, G. The microbuckling failure of Dyneema® composites under compression. Acta Mech. Solida Sin. 30, 425–434 (2017). https://doi.org/10.1016/j.camss.2017.06.002

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1016/j.camss.2017.06.002