Abstract

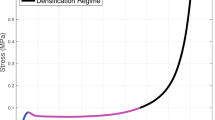

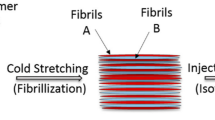

A complex rubber foam under quasi-static compression is simulated using the finite element method (FEM). The present work sets up the phenomenological constitutive model for the silicon rubber. The computerized tomography (CT) technique is utilized to reconstruct the real complex foam geometries. The quasi-static uniaxial compression on the foam is simulated in ABAQUS. The present work obtains the stress response as the nominal strain nearly reaches 80% and the foam exhibits hyper-elastic behavior. The FEM results achieve good agreements with the data obtained from the multi-scale simulation and the tests as the nominal strain is less than 60%.

Similar content being viewed by others

References

Y.Z. Wu, H.Y. Li, S.Y. Feng, Preparation of aminopropyl polysiloxane based heat curable silicone rubber, J. Mater. Sci. Eng. 22 (1) (2004) 41–43.

C.S. Zhang, C.H. Lu, Y.G. Huang, Effects of BPO/DCP on foam properties of silicon rubber, Silicon Mater. 24 (6) (2010) 373–376.

M.H. Chen, Q. Zhao, S.K. Luo, W.H. Lei, Y. Li, Effects of silica on the rheological and mechanical properties of the RTV silicone rubber foam, China Elastom. 21 (4) (2011) 15–19.

S. Sihn, A.K. Roy, Modeling and prediction of bulk properties of open-cell carbon foam, J. Mech. Phys. Solids 52 (2004) 167–191.

L. Gong, S. Kyriakides, W.Y. Jang, Compressive response of open-cell foams. Part I: Morphology and elastic properties, Int. J. Solids Struct. 42 (2005) 1355–1379.

L. Bardella, A. Sfreddo, C. Ventura, M. Porfiri, N. Gupta, A critical evaluation of micromechanical models for syntactic foams, Mech. Mater. 50 (2012) 53–69.

C. D’Angelo, A. Ortona, P. Colombo, Influence of the loading direction on the mechanical behavior of ceramic foams and lattices under compression, Acta Mater. 61 (2013) 5525–5534.

J.L. Zhang, Z.X. Lu, Numerical modeling of the compression process of elastic open-cell foams, Chin. J. Aeronaut. 20 (2007) 215–222.

C. Tekoglu, L.J. Gibson, T. Pardoen, P.R. Onck, Size effects in foams: experiments and modeling, Progr. Mater. Sci. 56 (2011) 109–138.

M. Yu, P. Zhu, Y. Ma, Effects of particle clustering on the tensile properties and failure mechanisms of hollow spheres filled syntactic foams: a numerical investigation by microstructure based modeling, Mater. Des. 47 (2013) 80–89.

Y. Chen, R. Das, M. Battley, Effects of cell size and cell wall thickness variations on the stiffness of closed-cell foams, Int. J. Solids Struct. 52 (2015) 150–164.

H.Y. Wang, W.J. Hu, Y.M. Yang, Multi-scale simulation of silicone rubber foam under compression, J. Mater. Sci. Eng. 32 (3) (2014) 376–379 348.

Author information

Authors and Affiliations

Corresponding author

Additional information

Project supported by the National Natural Science Foundation of China (No. 11272300) and the NSAF (No. U1530259).

Rights and permissions

About this article

Cite this article

Wang, H., Hu, W. & Zhao, F. Numerical simulation of quasi-static compression on a complex rubber foam. Acta Mech. Solida Sin. 30, 285–290 (2017). https://doi.org/10.1016/j.camss.2017.03.009

Published:

Issue Date:

DOI: https://doi.org/10.1016/j.camss.2017.03.009