Abstract

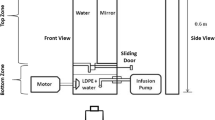

Bursting of gas bubbles on the free surface of liquid iron produces iron droplets that are ejected into the surrounding atmosphere. The influence of the freeboard pressure on gas bubble bursting was investigated by collecting and measuring the formed droplets in water and in liquid iron systems. In water model, it was found that gas bubbles expanded markedly during the floating up when the freeboard was evacuated but the influence of the freeboard pressure on the mass of ejection is not significant when the freeboard pressure varied from 0.01 to 0.1 MPa. Besides, in steel melt, the mass of ejection was increased by 2–3 times when the pressure was reduced from atmospheric pressure to 66.5 Pa.

Similar content being viewed by others

References

YU Neng-wen. Mathematical and Physical Modelling of Multi-Functional RH Refining Process [D]. Shanghai: Shanghai University of Technology, 2001 (in Chinese).

Kishimoto Y, Yamaguchi K, Sakuraya T, et al. Decarburization Reaction in Ultra-Low Carbon Iron Melt Under Reduced Pressure [J]. ISIJ Int. 1993, 33(3): 391.

Tatsuoka T, Kamata C, Ito K. Expansion of Injected Gas Bubble and Its Effects on Bath Mixing Under Reduced Pressure [J]. ISIJ Int, 1997, 37(6): 557.

Sakaguchi K, Ito K. Measurement of Volumetric Mass Transfer Coefficient of Gas-Stirred Vessel Under Reduced Pressure [J]. ISIJ Int, 1995: 35(11): 1348.

Iguchi M, Chihara T. Water Model Study of the Frequency of Bubble Formation Under Reduced and Elevated Pressures [J]. Metall Mater Trans, 1998, 29B: 755.

Han Z, Holappa L. Formation of Metal Droplets From Gas Bubbles Bursting on Iron Melts [J]. Steel Res, 2001, 72(11/ 12): 434.

Holappa L, Han Z, Morton D. Characterisation of Bubble Bursting in Argon/Molten Iron Systems [C] // ISS. The Belton Memorial Symposium Proc. Sydney: ISS, 2000; 63.

Han Z, Holappa L. Bubble Bursting Phenomenon in Gas/Metal/Slag Systems [J]. Metall Mater Trans, 2003, 34B(5): 525.

Szekely J, Fang S-D. Studies in Vacuum Degassing: Mass and Momentum Transfer to Gas Bubbles Rising in Melts, the Freeboard of Which is Evacuated [J]. Metall Trans, 1974, 5: 1429.

Allan R S, Charles G E, Mason S G. The Approach of Gas Bubbles to a Gas/Liquid Interface [J]. J Colloid Sci, 1961, 16: 150.

Charles G E, Mason J S G. The Coalescence of Liquid Drops With Flat Liquid/Liquid Interfaces [J]. J Colloid Sci, 1960, 15: 236.

Hartland S, Robinson J D. The Profile of the Draining Film Beneath a Liquid Drop Approaching a Plate Interface [J]. Can J Chem Eng, 1973, 51: 647.

Chevrier V, Cramb A. Observation and Measurement of Bubble Separation at Liquid-Liquid Interfaces [J]. Steel Res Int, 2004, 75(10): 645.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lin, P., Wang, Fl., Liu, L. et al. Characteristics of iron droplet ejection caused by gas bubble bursting under reduced pressure. J. Iron Steel Res. Int. 17, 7–11 (2010). https://doi.org/10.1016/S1006-706X(10)60036-2

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(10)60036-2