Abstract

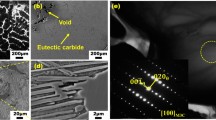

A new approach to applying the electric current pulse (ECP) with parallel electrodes to the promotion of the transition from columnar crystal to equiaxed crystal and the improvement of macrosegregation was introduced. The ECP was applied to different stages of the solidification. The results showed that the application of the ECP in both the initial stage (the thickness of solidified shell reached 2 mm approximately) and the late stage (the thickness of solidified shell reached 14 mm approximately) of solidification can promote the columnar to equiaxed transition (CET). The analysis showed that during solidification, a large number of nuclei around the upper surface fell off due to ECP, which subsequently showered on the melt and impinged the growth front of the columnar crystal. Therefore, the CET occurred. In addition, this method was also employed to influence the solidification process of bearing steel, and the results showed that the structure was changed from columnar crystal to equiaxed crystal, indicating that ECP can enhance the homogeneity of structure and composition of bearing steel.

Similar content being viewed by others

References

Kurz W, Bezencon C, Gaumann M. Columnar to Equiaxed Transition in Solidification Processing [J]. Sci Tech Adv Mater, 2001, 2(1): 185.

Canté Manuel V, Cruz Kleber S, Spinelli José E, et al. Experimental Analysis of the Columnar to Equiaxed Transition in Directionally Solidified Al-Ni and Al-Sn Alloys [J]. Mater Lett, 2007, 61(11–12): 2135.

Spittle J A. Columnar to Equiaxed Grain Transition in as Solidified Alloys [J]. Int Mater Rev, 2006, 51(4): 247.

Ohno A. The Effects of Rotation of Mold and Electromagnetic Stirring on the Structure of Aluminium Ingots [J]. J Jap Inst Met, 1977, 41(6): 545.

Ohno A, Motegi T, Shimizu T. The Formation of Equiaxed Crystals in Ammonium Chloride-Water Model and Al Alloy Ingots by Electromagnetic Stirring [J]. J Jap Inst Met, 1982, 46 (5): 554.

Sumio Kobayashi, Susumu Ishimura, Masahiro Yoshihara, et al. Factors Affecting Equiaxed Zone Generation in Electromagnetic Stirring [J]. Trans Iron Steel Inst Jap, 1988, 28(11): 939.

Griffiths W D, McCartney D G. The Effect of Electromagnetic Stirring on Macrostructure and Macrosegregation in the Aluminium Alloy 7150 [J]. Mater Sci Eng, 1997, 222A(2): 140.

Zhang W Q, Yang Y S, Zhu Y F, et al. Structural Transition and Macrosegregation of Al-Cu Eutectic Alloy Solidified in the Electromagnetic Centrifugal Casting Process [J]. Metall Mater Trans, 1998, 29A(1): 404.

Campanella T, Charbon C, Rappaz M. Grain Refinement Induced by Electromagnetic Stirring: Dendrite Fragmentation Criterion [J]. Metall Mater Trans, 2004, 35A(10): 3201.

Szajnar J. The Columnar Crystals Shape and Castings Structure Cast in Magnetic Field [J]. J Mater Proc Tech, 2004, 157–158: 761.

Willers B, Eckert S, Michel U, et al. The Columnar-to-Equiaxed Transition in Pb-Sn Alloys Affected by Electromagnetically Driven Convection [J]. Mater Sci Eng, 2005, 402A(1–2): 55.

Eckert S, Willers B, Nikrityuk P A, et al. Application of a Rotating Magnetic Field During Directional Solidification of Pb-Sn Alloys: Consequences on the CET [J]. Mater Sci Eng, 2005, 413–414A(12): 211.

Nafisi S, Emadib D, Shehata M T, et al. Effects of Electromagnetic Stirring and Superheat on the Microstructural Characteristics of Al-Si-Fe Alloy [J]. Mater Sci Eng, 2006, 432A (1–2): 71.

Morando R, Biloni H, Cole G S, et al. Development of Macrostructure in Ingots of Increasing Size [J]. Met Trans, 1970, 1(5): 1407.

Vivès C. Crystallization of Aluminum Alloys in the Presence of Vertical Electromagnetic Force Fields [J]. J Cryst Growth, 1997, 173(3–4): 541.

ZHAI Qi-jie, GAO Yu-lai. Metals Solidification Under the Influence of External Fields; Research Status in Shanghai University [A]. Han Q Y, Ludtka Gerard, Zhai Q J, eds. Materials Processing Under the Influence of External Fields [C]. Orlando: TMS, 2007. 45.

LIAO Xi-liang, ZHAI Qi-jie, LUO Jun, et al. Refining Mechanism of the Electric Current Pulse on the Solidification Structure of Pure Aluminum [J]. Acta Mater, 2007, 55(9): 3103.

Tarshis L A, Walker J L, Gigliotti M F X. Solidification [J]. Annu Rev Mater Sci, 1972, 2(9): 181.

Bruce Chalmers. Principles of Solidification [M]. New York: John Wiley and Sons Inc, 1964.

Jackson K A, Hunt J D, Uhlmann D R, et al. On the Origin of the Equiaxed Zone in Casting [J]. Trans Met Soc AIME, 1966, 236(2): 149.

Ohno A, Motegi T, Soda H. Origin of the Equiaxed Crystals in Castings [J]. Trans Iron Steel Inst Jap, 1971, 11(1): 18.

Davies G J. Solidification of Casting [M]. Essex: Applied Science Publishers Ltd, 1973.

Ohno A, Motegi T. Formation Mechanism of Equiaxed Zones in Cast Metals [J]. AFS 1m Cast Met J, 1977, 2(1): 28.

Gao J W, Wang C Y. An Experimental Investigation Into the Effects of Grain Transport on Columnar to Equiaxed Transition During Dendritic Alloy Solidification [J]. Journal of Heat Transfer, 1999, 121(2): 430.

Li Mingjun, Tamura Takuya, Miwa Kenji. Controlling Microstructures of AZ31 Magnesium Alloys by an Electromagnetic Vibration Technique During Solidification: From Experimental Observation to Theoretical Understanding [J]. Acta Mater, 2007, 55(14): 4635.

Krane M J M. Macrosegregation Development During Solidification of a Multicomponent Alloy With Free-Floating Solid Particles [J]. Applied Math Model, 2004, 28(1): 95.

Wang C Y, Beckermann C. Equiaxed Dendritic Solidification With Convection: Part I. Multiscale/Multiphase Modeling [J]. Metall Mater Trans, 1996, 27A(9): 2754.

Li J, Gao Y, Ma J, et al. The Effect on Solidification Structure of Bearing Steel by Electric Current Pulse With Low Voltage and High Discharging Frequency [A]. TMS, eds. TMS 2008 Annual Meeting Supplemental Proceedings: Volume 3: General Paper Selections [C]. New Orleans: TMS, 2008. 91.

Kato T, Jones H, Kirkwood D H. Segregation and Eutectic Formation in Solidification of Fe-1C-1.5Cr Steel [J]. Materials Science and Technology, 2003, 19(8): 1070.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation Item: Item Sponsored by National Natural Science Foundation of China (50674064, 50734008)

Rights and permissions

About this article

Cite this article

Li, J., Ma, Jh., Song, Cj. et al. Columnar to equiaxed transition during solidification of small ingot by using electric current pulse. J. Iron Steel Res. Int. 16, 7–12 (2009). https://doi.org/10.1016/S1006-706X(10)60019-2

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(10)60019-2