Abstract

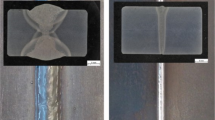

Electron-beam (EB) welding was used in T250 maraging steel, microstructures of both base material and heat affected zone (HAZ) were investigated by optical microscopy (OM), scanning electron microscopy (SEM) and transmission electron microscopy (TEM), and microhardness was tested. The results showed that during EB welding, the HAZ of T250 maraging steel exhibited a continuous gradient structure. The microstructure of the entire HAZ, from fusion line, could be divided into four zones: fusion zone, overheated zone, transition zone, and hardened zone. The microhardness showed a distinct regularity in each area. The softest region was the fusion zone, whereas the hardest was the hardened zone. In the overheated zone, the hardness increased as the grain size decreased. Furthermore, in the transition zone, the hardness level dropped noticeably. The peak temperature during the thermal cycle had a great influence on the formation of reverted austenite and dissolution of the precipitated particles, which contributed a lot to the microstructure and hardness of this material.

Similar content being viewed by others

References

Pardal J M, Tavares S S M, Terra V F, et al. Modeling of Precipitation Hardening During the Aging and Overaging of 18Ni-Co-Mo-Ti Maraging 300 Steel [J]. Journal of Alloys and Compounds, 2005, 393(1–2): 109.

Fathy Ayman, Mattar Taha. Mechanical Properties of New Low-Nickel Cobalt-Free Maraging Steels [J]. Steel Research, 2002, 73(12): 549.

ZHANG Jian-guo, SHI Yan-ling, ZHENG Shu-li. Research and Applications of Cobalt-Free Maraging Steels [J]. Heat Treatment of Metals, 2007, 32(2): 7 (in Chinese).

Akhtar F, Lian Y D, Islam S H, et al. A New Kind of Age Hardenable Martensitic Stainless Steel With High Strength and Toughness [J]. Ironmaking and Steelmaking, 2007, 34(4): 285.

Shamantha C R, Narayanan R, Iyer K J L, et al. Microstructural Changes During Welding and Subsequent Heat Treatment of 18Ni (250-Grade) Maraging Steel [J]. Materials Science and Engineering, 2000, 287A(1): 43.

Banas G, Elsayed-Ali H E. Laser Shock-Induced Mechanical and Microstructural Modification of Welded Maraging Steel [J]. Journal of Applied Physics, 1990, 67(5): 2380.

Sinha P P, Sivakumar D. Austenite Reversion in 18 Ni Co-Free Maraging Steel [J]. Steel Research, 1995, 66(11): 490.

Reddy G Madhusudhan, Mohandas T, Rao A Sambasiva, et al. Influence of Welding Processes on Microstructure and Mechanical Properties of Dissimilar Austenitic-Ferritic Stainless Steel Welds [J]. Materials and Manufacturing Processes, 2005, (20): 147.

Prasad Rao K, Venkitakrishnan P V. Electron Beam Welding of M-250 Grade Maraging Steel [J]. Praktische Metallographie, 1993, 30(3): 129.

CHEN Xiao-feng, LI Jia-han, LI Zhong-ku, et al. Study on Local Heat Transfer of 18Ni Maraging Steel After Electron Beam Welding [J]. Steel Research, 1994, 65(12): 557.

HU Zheng-fei, MO De-feng, WANG Chun-xu, et al. Different Behavior in Electron Beam Welding of 18 Ni Co-Free Maraging Steels [J]. Journal of Materials Engineering and Performance, 2007, 17(5): 767.

MA Cheng-yong, TIAN Zhi-ling, DU Ze-yu, et al. Characterization of the Microstructure and Hardness of the HAZ in a 800 MPa Grade RPC Steel [J]. China Welding, 2005, 14(1): 48.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation Item: Item Sponsored by National Natural Science Foundation of China (50771073)

Rights and permissions

About this article

Cite this article

Mo, Df., Hu, Zf., Chen, Sj. et al. Microstructure and Hardness of T250 Maraging Steel in Heat Affected Zone. J. Iron Steel Res. Int. 16, 87–91 (2009). https://doi.org/10.1016/S1006-706X(09)60016-9

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(09)60016-9