Abstract

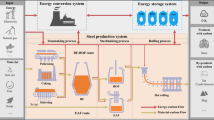

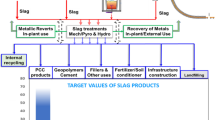

Sulfur flow for new generation steel manufacturing process is analyzed by the method of material flow analysis, and measures for SO2 emission reduction are put forward as assessment and target intervention of the results. The results of sulfur flow analysis indicate that 90% of sulfur comes from fuels. Sulfur finally discharges from the steel manufacturing route in various steps, and the main point is BF and BOF slag desulfurization. In sintering process, the sulfur is removed by gasification, and sintering process is the main source of SO2 emission. The sulfur content of coke oven gas (COG) is an important factor affecting SO2 emission. Therefore, SO2 emission reduction should be started from the optimization and integration of steel manufacturing route, sulfur burden should be reduced through energy saving and consumption reduction, and the sulfur content of fuel should be controlled. At the same time, BF and BOF slag desulfurization should be optimized further and coke oven gas and sintering exhausted gas desulfurization should be adopted for SO2 emission reduction and reuse of resource, to achieve harmonic coordination of economic, social, and environmental effects for sustainable development.

Similar content being viewed by others

References

ZHANG Chun-xia, QI Yuan-hong, YAN Ding-liu, et al. Energy-Saving and Environmental Protection of Ironmaking System in China [A]. The Iron and Steel Institute of Japan, eds. Asia Steel International Conference 2006 [C]. Fukuokat The Iron and Steel Institute of Japan. 2006. 48.

Paul H Brunner. Helmut Rechberger. Practical Handbook of Material Flow Analysis [M]. Boca Raton: CRC/Lewis, 2003.

Peter L Daniels, Stephen Moore. Approaches for Quantifying the Metabolism of Physical Economies, Part I: Methodological Overview [J]. Journal of Industrial Ecology, 2001, 5(4): 69.

Robert U Ayres. Industrial Metabolism: Theory and Policy. The Greening of Industrial Ecosystems [M]. Washington DC: National Academy Press, 1994.

http://www.worldsteel.org. World Steel in Figures 2006. Brussels.

Stoppa H, Strunk J. Costs and Environmental Impact of Dry and Wet Quenching [J]. Cokemaking International, 1999, 11 (1): 65.

Shinya IKEHARA, Susumu KUBO. Application of Exhaust Gas Recirculation System to Tobata No. 3 Sinter Plant [J]. Nippon Steel Technical Report, 1996, 360: 46.

WEN Guang-yuan. Iron-Making Metallurgy [M]. Chongqing: Chongqing University Publishing House, 1993 (in Chinese).

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation Item: Item Sponsored by National Natural Science Foundation of China (50334020)

Rights and permissions

About this article

Cite this article

Hu, Cq., Zhang, Cx., Han, Xw. et al. Sulfur flow analysis for new generation steel manufacturing process. J. Iron Steel Res. Int. 15, 12–15 (2008). https://doi.org/10.1016/S1006-706X(08)60136-3

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(08)60136-3