Abstract

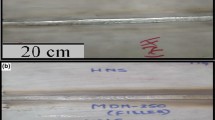

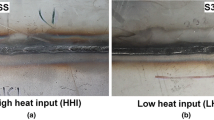

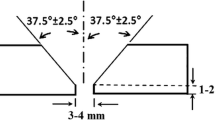

The welding of nitrogen (0.29 wt%)-alloyed austenitic steel (grade 23-8-N) was performed with gas metal arc welding process. Solution treatment was performed at 950 °C and 1150 °C on base metal prior to weld. Base metal after second treatment has maximum ultimate tensile strength of 942 MPa and impact toughness 66 J. The microstructures of different zones of the weld joint were characterized using an optical microscope and field scanning electron microscope (FESEM). The microhardness, tensile and impact toughness tests of the weldments were conducted along with weld ferrite evaluation. ER2209 duplex filler metal used for welding has lower C and N content which changed the weld solidification mode. Weld has microstructure containing austenite + ferrite. Being a strong austenite former, nitrogen caused minimum ferrite near weld–HAZ interface while maximum ferrite content was observed at weld centre. Weld metal has minimum while base metal has maximum microhardness. UTS (892 MPa) and impact strength (96 J) of weld made on 1150 °C solution-treated base metal were maximum as compared to other weld joints.

Similar content being viewed by others

References

Zhao L, Tian ZL, Peng Y. Control of nitrogen content and porosity in gas tungsten arc welding of high nitrogen steel. Sci Technol Weld Join. 2009;14:87–92. https://doi.org/10.1179/136217108X343939.

Lo KH, Shek CH, Lai JKL. Recent developments in stainless steels. Mater Sci Eng R Rep. 2009;65:39–104. https://doi.org/10.1016/j.mser.2009.03.001.

Korshunov LG, Goikhenberg YN, Chernenko NK. Effect of alloying and heat treatment on the structure and tribological properties of nitrogen-bearing stainless austenitic steels under abrasive and adhesive wear. Met. Sci. Heat Treat. 2007;49:5–6. https://link.springer.com/content/pdf/10.1007%2Fs11041-007-0039-0.pdf Accessed 1 Aug 2019.

Chauhan AK, Goel DB, Prakash S. Solid particle erosion behaviour of 13Cr–4Ni and 21Cr–4Ni–N steels. J Alloys Compd. 2009;467:459–64. https://doi.org/10.1016/j.jallcom.2007.12.053.

Kumar A, Sharma A, Goel SK. Effect of heat treatment on microstructure, mechanical properties and erosion resistance of cast 23–8-N nitronic steel. Mater Sci Eng A. 2015;637:56–62. https://doi.org/10.1016/J.MSEA.2015.04.031.

Gadhikar AA. Characterization study of steels for erosion resistant applications, Ph.D. thesis, MNIT, Jaipur, MNIT Jaipur, 2011.

Pan DZ, Farson DF. Simulation of nitrogen transport and desorption in laser welds of 21Cr–6Ni–9Mn stainless steel. Sci Technol Weld Join. 2014;19:646–52. https://doi.org/10.1179/1362171814Y.0000000238.

Hosseini VA, Wessman S, Hurtig K, Karlsson L. Nitrogen loss and effects on microstructure in multipass TIG welding of a super duplex stainless steel. Mater Des. 2016. https://doi.org/10.1016/j.matdes.2016.03.011.

Galloway AM, Mcpherson NA, Baker TN. An evaluation of weld metal nitrogen retention and properties in 316LN austenitic stainless steel. Proc Inst Mech Eng Part L J Mater Des Appl. 2011;225:1–9. https://doi.org/10.1177/1464420711398608.

Zhao L, Tian Z, Peng Y. Porosity and nitrogen content of weld metal in laser welding of high nitrogen austenitic stainless steel. ISIJ Int. 2007;47:1772–5. https://doi.org/10.2355/isijinternational.47.1772.

Qiang W, Wang K. Shielding gas effects on double-sided synchronous autogenous GTA weldability of high nitrogen austenitic stainless steel. J Mater Process Technol. 2017;250:169–81. https://doi.org/10.1016/j.jmatprotec.2017.07.021.

Woo I, Aritoshi M, Kikuchi Y. Metallurgical and mechanical properties of high nitrogen austenitic stainless steel friction welds. ISIJ Int. 2002;42:401–6. https://doi.org/10.2355/isijinternational.42.401.

Li HB, Jiang ZH, Feng H, Zhang SC, Li L, Han PD, Misra RDK, Li JZ. Microstructure, mechanical and corrosion properties of friction stir welded high nitrogen nickel-free austenitic stainless steel. Mater Des. 2015;84:291–9. https://doi.org/10.1016/j.matdes.2015.06.103.

A.A. Gadhikar, C.P. Sharma, D.B. Goel, A. Sharma, Effect of Heat Treatment on Carbides in 23–8-N Steel, Met. Sci. Heat Treat. 53 (2011) 293–298. https://link.springer.com/content/pdf/10.1007%2Fs11041-011-9385-z.pdf Accessed 15 Sept 2018.

Gadhikar AA, Sharma A, Goel DB, Sharma CP. Effect of carbides on erosion resistance of 23-8-N steel. Bull Mater Sci. 2014;37:315–9.

Ranjbarnodeh E, Pouraliakbar H, Kokabi AH. Finite element simulation of carbide precipitation in austenitic stainless steel 304. Int J Mech Appl. 2012;2:117–23. https://doi.org/10.5923/j.mechanics.20120206.03.

Kumar N, Arora N, Goel SK. Effect of base metal solution annealing on mechanical and metallurgical properties of GMA welded nitronic steel. Mater Sci Eng A. 2020. https://doi.org/10.1016/j.msea.2019.138542.

Pouraliakbar H, Hamedi M, Kokabi AH, Nazari A. Designing of CK45 carbon steel and aisi 304 stainless steel dissimilar welds. Mater Res. 2014;17:106–14. https://doi.org/10.1590/S1516-14392013005000170.

Bermejo MAV. Predictive and measurement methods for delta ferrite determination in stainless steels. Weld J. 2012;91:113–21.

Fu JW, Yang YS, Guo JJ. Formation of a blocky ferrite in Fe–Cr–Ni alloy during directional solidification. J Cryst Growth. 2009;311:3661–6. https://doi.org/10.1016/J.JCRYSGRO.2009.05.007.

Tate SB, Liu S. Solidification behaviour of laser welded type 21Cr–6Ni–9Mn stainless steel. Sci Technol Weld Join. 2014;19:310–7. https://doi.org/10.1179/1362171813Y.0000000189.

Vashishtha H, Taiwade RV, Sharma S, Patil AP. Effect of welding processes on microstructural and mechanical properties of dissimilar weldments between conventional austenitic and high nitrogen austenitic stainless steels. J Manuf Process. 2017;25:49–59. https://doi.org/10.1016/J.JMAPRO.2016.10.008.

Pfeif EA. Characterization of nitrogen effects in high energy density weldments of Nitronic 40 stainless steel—ProQuest, Colorado School of Mines, United States, 2015. https://search.proquest.com/docview/1696057880 Accessed 11 Jan 2020.

Sarkari-Khorrami M, Mostafaei MA, Pouraliakbar H, Kokabi AH. Study on microstructure and mechanical characteristics of low-carbon steel and ferritic stainless steel joints. Mater Sci Eng A. 2014;608:35–45. https://doi.org/10.1016/j.msea.2014.04.065.

Kumar N, Arora N, Goel SK, Goel DB. A comparative study of microstructure and mechanical properties of 21-4-N steel weld joints using different filler materials. Mater Today Proc. 2018;5:17089–96. https://doi.org/10.1016/j.matpr.2018.04.116.

Gavriljuk VG, Berns H, Escher C, Glavatskaya NI, Sozinov A, Petrov YN. Grain boundary strengthening in austenitic nitrogen steels. Mater Sci Forum. 2009;318–320:455–60. https://doi.org/10.4028/www.scientific.net/msf.318-320.455.

Pandey C, Mahapatra MM. Effect of heat treatment on microstructure and hot impact toughness of various zones of P91 welded pipes. J Mater Eng Perform. 2016. https://doi.org/10.1007/s11665-016-2064-x.

Acknowledgements

The authors gratefully acknowledge Prof. Desh Bandhu Goel, Indian Institute of Technology, Roorkee, for giving their technical inputs. The authors are also thankful to Star Wire (India) Ltd. for providing material to perform the study.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There is no conflict of interest.

Ethical statement

I ensure that the work described has been carried out in accordance with Publishing Ethics.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kumar, N., Arora, N. & Goel, S.K. Weld joint properties of nitrogen-alloyed austenitic stainless steel using multi-pass GMA welding. Archiv.Civ.Mech.Eng 20, 82 (2020). https://doi.org/10.1007/s43452-020-00087-1

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43452-020-00087-1