Abstract

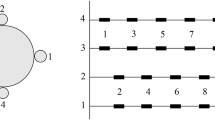

Improving the accuracy of shape sensors based on multicore fibers (MCFs) is challenging but of great importance for real-time 3D shape detection, especially in visually inaccessible areas. In this work, a novel approach is proposed to improve MCF shape sensor accuracy using an ultraviolet transparent liquid mediated fiber Bragg grating (FBG) inscription technique and a twist-isolating packaging method. A newly developed UV index matching liquid (UV-IML) is used to generate uniform light field at all the MCF cores, enabling FBG inscription with high accuracy. Additionally, a new stress fully released (SFR) packaging method is implemented to isolate the sensor from any external twists. The MCF shape sensor shows a maximum relative error of only 3.33% and the lowest reported relative sensitivity error of 1.11% cm−1. Moreover, a real-time 3D shape sensing system with a response frequency larger than 30 Hz is constructed using the unique MCF shape sensor. The highly accurate real-time 3D shape sensing results indicate potential applications for in vivo shape estimation of endoscopies and soft robots.

Graphical abstract

A highly accurate MCF shape sensor for real-time 3D shape detection in visually inaccessible areas is developed. The MCF shape sensor shows a maximum relative error of 3.33% and the lowest reported relative sensitivity error of 1.11% cm−1. The novel ultraviolet index matching liquid FBG inscription method and stress fully released packaging method ensures high accuracy.

Similar content being viewed by others

Data availability

Data underlying the results presented in this paper are not publicly available at this time but may be obtained from the authors upon reasonable request.

References

Li YP, Zhang Y, Li Z, Yan ZJ, Xiao XP, Liu XT, Chen J, Shen Y, Sun QZ, Huang YH. Operando decoding of surface strain in anode-free lithium metal batteries via optical fiber sensor. Adv Sci. 2022;9:2203247.

Ko W, Feder KS, Sun XG, Li J, Westbrook PS. Simultaneous interrogation of multiple cores in a shape sensor fiber with a graded index fiber micro-turnaround. Opt Express. 2022;30:24452.

Floris I, Adam JM, Calderón PA, Sales S. Fiber optic shape sensors: a comprehensive review. Opt Lasers Eng. 2021;139: 106508.

Zheng HR, Jiang Y, Angelmahr M, Flachenecker G, Cai HW, Schade W. Artificial neural network for the reduction of birefringence-induced errors in fiber shape sensors based on cladding waveguides gratings. Opt Lett. 2020;45:1726.

Zafeiropoulou A, Masoudi A, Zdagkas A, Cooper L, Brambilla G. Curvature sensing with a D-shaped multicore fiber and Brillouin optical time-domain reflectometry. Opt Express. 2020;28:1291.

Yin GL, Lu L, Zhou L, Shao C, Fu QJ, Zhang JD, Zhu T. Distributed directional torsion sensing based on an optical frequency domain reflectometer and a helical multicore fiber. Opt Express. 2020;28:16140.

Yi XH, Chen XY, Fan HC, Shi F, Cheng XM, Qian JW. Separation method of bending and torsion in shape sensing based on FBG sensors array. Opti Express. 2020;2:9367.

Lai TT, Cheng P, Yan CL, Li C, Hu WB, Yang MH. 2D and 3D shape sensing based on 7-core fiber Bragg gratings. Photonic Sens. 2020;10:306.

Moore JP, Rogge MD. Shape sensing using multi-core fiber optic cable and parametric curve solutions. Opt Express. 2012;20:2967.

Zafeiropoulou A, Masoudi A, Cooper L, Brambilla G. Flat multi-core fibre for twist elimination in distributed curvature sensing. Opt Fiber Technol. 2021;66: 102663.

Zhou R, Chen FY, Li SS, Wang RH, Qiao XG. Three-dimensional vector accelerometer using a multicore fiber inscribed with three FBGs. J Lightwave Technol. 2021;39:3244.

Westbrook PS, Kremp T, Feder KS, Ko W, Monberg EM, Wu H, Simoff DA, Taunay TF, Ortiz RM. Continuous multicore optical fiber grating arrays for distributed sensing applications. J Lightwave Technol. 2017;35:1248.

Zhao ZY, Dang YL, Tang M. Advances in multicore fiber grating sensors. Photonics. 2022;9:381.

Froggatt M, Soller B, Gifford D, Wolfe M. Correlation and keying of Rayleigh scatter for loss and temperature sensing in parallel optical networks. In: Optical fiber communication conference (OFC); 2004. PDP17.

Zhang HL, Wu ZF, Shum PP, Wang RX, Dinh XQY, Fu SN, Tong WJ, Tang M. Fiber Bragg gratings in heterogeneous multicore fiber for directional bending sensing. J Opt. 2016;18: 085705.

Khan F, Barrera D, Sales S, Misra S. Curvature, twist and pose measurements using fiber Bragg gratings in multi-core fiber: a comparative study between helical and straight core fibers. Sens Actuat A-Phys. 2021;317: 112442.

Xiao XZ, Xu BJ, Xu XZ, Du B, Chen ZY, Fu CL, Liao CR, He J, Wang YP. Femtosecond laser auto-positioning direct writing of a multicore fiber Bragg grating array for shape sensing. Opt Lett. 2022;47:758.

Hou MX, Yang KM, He J, Xu XZ, Ju S, Guo KK, Wang YP. Two-dimensional vector bending sensor based on seven-core fiber Bragg gratings. Opt Express. 2018;26:23770.

Lindley E, Min S-S, Leon-Saval S, Cvetojevic N, Lawrence J, Ellis S, Bland-Hawthorn J. Demonstration of uniform multicore fiber Bragg gratings. Opt Express. 2014;22:31575.

Yang KM, He J, Liao CR, Wang Y, Liu S, Guo KK, Zhou JT, Li ZY, Tan Z, Wang YP. Femtosecond laser inscription of fiber Bragg grating in twin-core few-mode fiber for directional bend sensing. J Lightwave Technol. 2017;35:4670.

Wolf A, Dostovalov A, Bronnikov K, Babin S. Arrays of fiber Bragg gratings selectively inscribed in different cores of 7-core spun optical fiber by IR femtosecond laser pulses. Opt Express. 2019;27:13978.

Bronnikov K, Wolf A, Yakushin S, Dostovalov A, Egorova O, Zhuravlev S, Semjonov S, Wabnitz S, Babin S. Durable shape sensor based on FBG array inscribed in polyimide-coated multicore optical fiber. Opt Express. 2019;27:38421.

Li JW, Thiele S, Quirk BC, Kirk RW, Verjans JW, Akers E, Bursill CA, Nicholls SJ, Herkommer AM, Giessen H, McLaughlin RA. Ultrathin monolithic 3D printed optical coherence tomography endoscopy for preclinical and clinical use. Light-Sci Appl. 2020;9:124.

Askins CG, Miller GA, Friebele EJ. Bend and twist sensing in a multiple-core optical fiber. In: Conference on Optical Fiber Communication/National Fiber Optic Engineers Conference (OFC/NFOEC); 2008. pp. OMT3.

Westbrook P, Feder K, Kremp T, Taunay T, Monberg E, Kelliher J, Ortiz R, Bradley K, Abedin K, Au D, Puc G. Integrated optical fiber shape sensor modules based on twisted multicore fiber grating arrays. In: Optical Fibers and Sensors for Medical Diagnostics and Treatment Applications XIV; 2014. 89380H-1.

Modes V, Ortmaier T, Burgner-Kahrs J. Shape sensing based on longitudinal strain measurements considering elongation, bending, and twisting. IEEE Sens J. 2021;21:6712.

Cooper L, Webb A, Gillooly A, Hill M, Read T, Maton P, Hankey J, Bergonzo A. Design and performance of multicore fiber optimized towards communications and sensing applications. In: Optical Components and Materials XII (OPTO). 2015. pp. 93590H.

Jäckle S, Eixmann T, Schulz-Hildebrandt H, Hüttmann G, Pätz T. Fiber optical shape sensing of flexible instruments for endovascular navigation. Int J Comput Assist Radiol Surg. 2019;14:2137.

Idrisov R, Becker M, Rothhardt M, Bierlich J, Bartelt H, editors. Optimisation of fibre Bragg gratings inscription in multicore fibres. In: Optical Fiber Sensors; 2018. p WF64.

Hoffnagle JA, Hinsberg WD, Sanchez M, Houle FA. Liquid immersion deep-ultraviolet interferometric lithography. J Vac Sci Technol B. 1999;17:3306.

Yu YJ, Shi JD, Han F, Sun WJ, Feng X. High-precision fiber Bragg gratings inscription by infrared femtosecond laser direct-writing method assisted with image recognition. Opt Express. 2020;28:8937.

Moore JP. Shape sensing using multi-core fiber. In: Optical Fiber Communications Conference and Exhibition (OFC); 2015. pp. Th1C.2.

Khan F, Donder A, Galvan S, Baena FRY, Misra S. Pose measurement of flexible medical instruments using fiber Bragg gratings in multi-core fiber. IEEE Sens J. 2020;20:10955.

Company TSSC. Shape sensing with heart model. 2021. https://www.youtube.com/watch?v=uEHVE0Vo5Q0.

Acknowledgements

The research was supported by the Major Scientific Research Project of Zhejiang Laboratory (No. 2019MC0AD02), the Innovation Project of Zhejiang Laboratory (No. 2022MG0AL03), the National Science Foundation of China (Nos. 62204230, 62020106002, T2293750, 62205306, 92250304), and the National Key Research and Development Program of China (2021YFC2401403). We would like to thank Dr. Fu Feng and Mr. Qilin Deng for their help in revising English writing.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Supplementary file2 (MP4 24524 KB)

Supplementary file3 (MP4 29214 KB)

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Meng, L., Xu, H., Huang, Y. et al. High-Accuracy 3D Shape Sensor Based on Anti-Twist Packaged High Uniform Multicore Fiber FBGs. Adv. Fiber Mater. 5, 1467–1477 (2023). https://doi.org/10.1007/s42765-023-00285-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42765-023-00285-5