Abstract

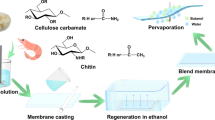

In this work, the silk fibroin/cellulose blend nanofibrous membranes modified with sodium-3-sulfobenzoate (S-SCBNM) were fabricated by electrospinning technique for lysozyme adsorption. The morphology and structure of membranes was observed. The effect of sulfate contents, pH values and concentration of lysozyme on adsorption performance were studied, respectively. The reuse capacity was evaluated. The results showed that the resultant S-SCBNM exhibited integrated properties of ultrathin fiber diameter (148 nm), fast adsorption equilibrium, excellent adsorption performance (636 mg g−1) and good reversibility. We envision that this new class of green and natural blend membranes is particularly promising for the development of proteins separation.

Similar content being viewed by others

References

Li J, Si Y, Zhao C. Spontaneous and efficient adsorption of lysozyme from aqueous solutions by naturally polyanion gel beads. Mater Sci Eng C. 2017;76:130–8.

Li J, Wei X, He J. Tailored natural polysaccharides beads as green sorbents for efficient lysozyme adsorption. J Polym Environ. 2018;26:2803–12.

Zhang Y, Xing L, Chen X. Nano copper oxide-incorporated mesoporous carbon composite as multimode adsorbent for selective isolation of hemoglobin. ACS Appl Mater Inter. 2015;7:5116–23.

Kubo T, Arimura S, Tominaga Y. Molecularly imprinted polymers for selective adsorption of lysozyme and cytochrome c using a PEG-based hydrogel: selective recognition for different conformations due to pH conditions. Macromolecules. 2015;48:4081–7.

Chen K, Chou S, Chang Y. Rapid purification of lysozyme by mixed-mode adsorption chromatography in stirred fluidized bed. Food Chem. 2019;272:619–27.

Alveroglu E, İlker N, Shah M. Effects of gel morphology on the lysozyme adsorption and desorption kinetics of temperature sensitive magnetic gel composites. Colloid Surface B. 2019;181:981–8.

Ma L, Pang D, Deng C. Competitive adsorption of bovine serum albumin and lysozyme on a beta-tricalcium phosphate nanocoating. Colloid Surf A Physicochem Eng Asp. 2019;582:123860.

Amaly N, Ma Y, El-Moghazy A. Copper complex formed with pyridine rings grafted on cellulose nanofibrous membranes for highly efficient lysozyme adsorption. Sep Purif Technol. 2020;5:117086.

Brassesco M, Valetti G, Picó N. Molecular mechanism of lysozyme adsorption onto chemically modified alginate guar gum matrix. Int J Biol Macromol. 2017;96:111–7.

Boeris V, Vennapusa R, Rodríguez M. Production, recovery and purification of a recombinant β-galactosidase by expanded bed anion exchange adsorption. J Chromatogr B. 2012;900:32–7.

Enayatpour B, Rajabi M, Moradi O. Adsorption kinetics of lysozyme on multi-walled carbon nanotubes and amino functionalized multi-walled carbon nanotubes from aqueous solution. J Mol Liq. 2018;254:93–7.

Su C, Lai C, Yeh L. The characteristics of a preservative-free contact lens care solution on lysozyme adsorption and interfacial friction behavior. Colloid Surface B. 2018;171:538–43.

Yi S, Dai F, Ma Y, et al. Ultrafine silk-derived nanofibrous membranes exhibiting effective lysozyme adsorption. ACS Sustain Chem Eng. 2017;5:8777–84.

Zhou Z, Shi Z, Cai X. The use of functionalized silk fibroin films as a platform for optical diffraction-based sensing applications. Adv Mater. 2017;29:1605471.

Tamada Y. Sulfation of silk fibroin by chlorosulfonic acid and the anticoagulant activity. Biomaterials. 2004;25:377–83.

Ling S, Li C, Jin K. Liquid exfoliated natural silk nanofibrils: applications in optical and electrical devices. Adv Mater. 2016;28:7783–90.

Papke M, Schulz S, Tichy H. Identification of a new sex pheromone from the silk dragline of the tropical wandering spider Cupiennius salei. Angew Chem Int Ed. 2000;39:4339–41.

Zhou W, He J, Cui S. Preparation of electrospun silk fibroin/cellulose acetate blend nanofibers and their applications to heavy metal ions adsorption. Fiber Polym. 2011;12:431–7.

Zhou W, He J, Du S. Electrospun silk fibroin/cellulose acetate blend nanofibres: structure and properties. Iran Polym J. 2011;20:389–97.

Feng Y, Li X, Li M. Facile preparation of biocompatible silk fibroin/cellulose nanocomposite films with high mechanical performance. ACS Sustain Chem Eng. 2017;5:6227–36.

Feng Y, Li X, Zhang Q. Fabrication of porous silk fibroin/cellulose nanofibril sponges with hierarchical structure using a lithium bromide solvent system. Cellulose. 2019;26:1013–23.

Park K, Jung S, Lee S. Biomimetic nanofibrous scaffolds: preparation and characterization of chitin/silk fibroin blend nanofibers. Int J Biol Macromol. 2006;38:165–73.

Chang S, Eun H. Nanofibrous membrane of wool keratose/silk fibroin blend for heavy metal ion adsorption. J Membrane Sci. 2007;302:20–6.

Cheung H, Lau K, Tao X. A potential material for tissue engineering: silkworm silk/PLA biocomposite. Compos Part B Eng. 2008;39:1026–33.

Jin H, Fridrikh S, Rutledge G. Electrospinning Bombyx mori silk with poly (ethylene oxide). Biomacromol. 2002;3:1233–9.

Yi S, Dai F, Wu Y. Scalable fabrication of sulfated silk fibroin nanofibrous membranes for efficient lipase adsorption and recovery. Int J Biol Macromol. 2018;111:738–45.

Fu Q, Wang X, Si Y, et al. Scalable fabrication of electrospun nanofibrous membranes functionalized with citric acid for high-performance protein adsorption. ACS Appl Mater Inter. 2016;8:11819–29.

Yi S, Dong Y, Li B. Adsorption and fixation behaviour of CI Reactive Red 195 on cotton woven fabric in a nonionic surfactant Triton X-100 reverse micelle. Color Technol. 2012;128:306–14.

Sun S, Zhang Y, Zou Y. Adsorption and dyeing properties of acid dyes on fine denier silk fibers. Text Res J. 2020;90:433–41.

Tan I, Hameed B, Ahmad A. Equilibrium and kinetic studies on basic dye adsorption by oil palm fibre activated carbon. Chem Eng J. 2007;127:111–9.

Shen W, Chen S, Shi S. Adsorption of Cu (II) and Pb (II) onto diethylenetriamine-bacterial cellulose. Carbohyd Polym. 2009;75:110–4.

Yi S, Sun S, Zhang Y, et al. Scalable fabrication of bimetal modified polyacrylonitrile (PAN) nanofibrous membranes for photocatalytic degradation of dyes. J Colloid Interf Sci. 2020;559:134–42.

Yi S, Zou Y, Sun S, et al. Rechargeable photoactive silk-derived nanofibrous membranes for degradation of reactive red 195. ACS Sustain Chem Eng. 2019;7:986–93.

Alhumaimess M. Adsorption kinetic and thermodynamic studies of safranin and methylene blue on a novel adsorbent based on phosphorylated sawdust. Desalin Water Treat. 2019;151:199–211.

Fiaz R, Hafeez M, Mahmood R. Ficcus palmata leaves as a low-cost biosorbent for methylene blue: Thermodynamic and kinetic studies. Water Environ Res. 2019;91:689–99.

Gemici B, Ozel H. Adsorption behaviors of crystal violet from aqueous solution using Anatolian black pine (Pinus nigra Arnold.): kinetic and equilibrium studies. Sep Sci Technol. 2020;55:406–14.

Kumar G, Chandra M. Removal of arsenite from aqueous solution using activated carbon derived from Eichhornia crassipes root biomass: Equilibrium, kinetic, thermodynamic and column studies. Res J Chem Environ. 2019;23:94–105.

Ma J, Wang X, Fu Q, et al. Highly carbonylated cellulose nanofibrous membranes utilizing maleic anhydride grafting for efficient lysozyme adsorption. ACS Appl Mater Interfaces. 2015;7:15658–66.

Wang X, Fu Q, Wang X. In situ cross-linked and highly carboxylated poly (vinyl alcohol) nanofibrous membranes for efficient adsorption of proteins. J Mater Chem B. 2015;3:7281–90.

Funding

The authors acknowledge the National Natural Science Foundation of China (No. 21506173) and Undergraduates' Innovation and Entrepreneurship Training Program in Southwest University (No. P202110635060).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Zhou, Y., Wu, J., Li, Y. et al. Fabrication of Sulfated Silk Fibroin-Based Blend Nanofibrous Membranes for Lysozyme Adsorption. Adv. Fiber Mater. 4, 89–97 (2022). https://doi.org/10.1007/s42765-021-00104-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42765-021-00104-9