Abstract

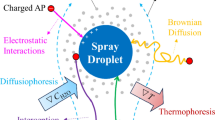

The impact of graphite dust on structural equipment is a potential safety hazard in HTGR. The present study focuses on the graphite particle deposition process on the deflector in the inlet passageway of intermediate heat exchanger and analyzes the effect of particle size on inertial deposition and diffusion deposition. Meanwhile, the particle rebound behavior is considered when the particle impacts the wall. To determine the relevant parameters of the rebound model, the experiments about adhesion are carried out and validated. Then the flow field is simulated in the inlet passageway of intermediate heat exchanger based on k–ε turbulent model, and particle trajectories are predicted by a discrete particle model with rebound boundary. The results show that adhesion force by measures is obviously smaller than theoretical model. In addition, the particle deposition rate decreases first and then increases, and the rebound model makes d eposition results more actual.

Similar content being viewed by others

Change history

05 February 2022

A Correction to this paper has been published: https://doi.org/10.1007/s42757-022-0132-z

References

Barth, T., Kulenkampff, J., Bras, S., Gründig, M., Lippmann-Pipke, J., Hampel, U. 2014. Positron emission tomography in pebble beds. Part 2: Graphite particle deposition and resuspension. Nucl Eng Des, 267: 227–237.

Baxter, L. L., Smith, P. J. 1993. Turbulent dispersion of particles: The STP model. Energ Fuel, 7: 852–859.

Cui, J., Yuan, K., Sun, Q., Peng, W., Wang, J. 2018. Inlet passageway optimization of immediate heat exchanger in an HTGR. In: Proceedings of the 26th International Conference on Nuclear Engineering, 9: V009T16A056.'

Dong, M., Han, J., Li, S. F., Pu, H. 2013a. A dynamic model for the normal impact of fly ash particle with a planar surface. Energies, 6: 4288–4307.

Dong, M., Li, S. F., Xie, J., Han, J. 2013b. Experimental studies on the normal impact of fly ash particles with planar surfaces. Energies, 6: 3245–3262.

Gosman, A. D., Ioannides, E. 1983. Aspects of computer simulation of liquid-fuelled combustors. J Energy, 7: 482–490.

Gutti, V. R., Loyalka, S. K. 2009. Thermophoretic deposition in a cylindrical tube: Computations and comparison with experiments. Nucl Technol, 166: 121–133.

Hertz, H. 1882. Uber die Beruhrung fester elastischer Korper. J reine und angewandte Mathematik, 92: 156–171.

Hosseini, S. B., Khoshkhoo, R. H., Malabad, S. M. J. 2017. Experimental and numerical investigation on particle deposition in a compact heat exchanger. Appl Therm Eng, 115: 406–417.

Humrickhouse, P. W. 2011. HTGR dust safety issues and needs for research and development. Technical Report. Idaho National Laboratory, DOI: 10.2172/1023483.

IAEA. 1997. Fuel performance and fission product behavior in gascooled reactors. IAEA-TECDOC-978.

Jayaraju, S. T., Roelofs, F., Komen, E. M. J., Dehbi, A. 2016. RANS modeling of fluid flow and dust deposition in nuclear pebblebeds. Nucl Eng Des, 308: 222–237.

Johnson, K. L., Kendall, K., Roberts, A. D. 1971. Surface energy and the contact of elastic solids. Proc R Soc Lond A, 324: 301–313.

Kawahara, A., Chung, P. M. Y., Kawaji, M. 2002. Investigation of two-phase flow pattern, void fraction and pressure drop in a microchannel. Int J Multiphase Flow, 28: 1411–1435.

Kazuhiro, S., Takeshi, N., Yoshiaki, M. 1992. Experimental study of dust behavior during depressurization. J Nucl Sci Technol, 29: 1018–1025.

Kim, O. V., Dunn, P. F. 2007. A microsphere-surface impact model for implementation in computational fluid dynamics. J Aerosol Sci, 38: 532–549.

Kim, O. V., Dunn, P. F. 2008. Direct visualization and model validation of microsphere impact and surface capture. J Aerosol Sci, 39: 373–375.

Kissane, M. P. 2009. A review of radionuclide behaviour in the primary system of a very-high-temperature reactor. Nucl Eng Des, 239: 3076–3091.

Kissane, M. P., Zhang, F., Reeks, M. W. 2012. Dust in HTRs: Its nature and improving prediction of its resuspension. Nucl Eng Des, 251: 301–305.

Kleinhans, U., Wieland, C., Frandsen, F. J., Spliethoff, H. 2018. Ash formation and deposition in coal and biomass fired combustion systems: Progress and challenges in the field of ash particle sticking and rebound behavior. Prog Energ Combust, 68: 65–168.

Launder, B. E., Spalding, D. B. 1972. Lectures in Mathematical Models of Turbulence. London: Academic Press.

Li, R. Z., Li, X. T., Fu, J. Y. 2000. The design of intermediate heat exchanger (IHX) for HTR-10. High Technology Letters, 10: 23–25. (in Chinese)

Lind, T., Güntay, S., Dehbi, A., Liao, Y., Rycroft, C. H. 2010. PSI project on HTR dust generation and transport. In: Proceedings of HTR.

Mokgalapa, N. M., Ghosh, T. K., Loyalka, S. K. 2014. Graphite particle adhesion to hastelloy X: Measurements of the adhesive force with an atomic force microscope. Nucl Technol, 186: 45–59.

Morsi, S. A., Alexander, A. J. 1972. An investigation of particle trajectories in two-phase flow systems. J Fluid Mech, 55: 193–208.

Peng, W., Sun, Q., Xie, F., Jiang, Y. 2018. Simulations of the dust behavior in the sampling and dust filters in the primary loop of HTR-10. Nucl Eng Des, 340: 112–121.

Peng, W., Zhen, Y. N., Yang, X. Y., Yu, S. Y. 2013. Graphite dust deposition in the HTR-10 steam generator. Particuology, 11: 533–539.

Sun, Q., Chen, T., Peng, W., Wang, J., Yu, S. Y. 2018. A numerical study of particle deposition in HTGR steam generators. Nucl Eng Des, 332: 70–78.

US DOE Nuclear Energy Research Advisory Committee. 2002. A technology roadmap for generation IV nuclear energy systems. GIF-002-00.

Wei, M. Z., Zhang, Y. Y., Wu, X. X., Sun, L. B. 2019. A parametric study of graphite dust deposition on high-temperature gas-cooled reactor (HTGR) steam generator tube bundles. Ann Nucl Energy, 123: 135–144.

Williams, M. M. R., Loyalka, K. S. 1991. Aerosol Science—Theory and Practice: With Special Applications to the Nuclear Industry. Pergamon.

Xie, F., Li, H., Cao, J., Yu, S., Zhang, L., Li, W., Fang, S. 2013. A reform in the helium purification system of the HTR-10: γ dose rate measurement and suggestions for decommissioning. In: Proceedings of the 15th International Conference on Environmental Remediation and Radioactive Waste Management, 2: V002T03A019

Yu, B., Zhang, W. Q., Xu, J. M., Chen, J. 2010. Status and research of highly efficient hydrogen production through high temperature steam electrolysis at INET. Int J Hydrogen Energ, 35: 2829–2835.

Zhang, T. Q., Peng, W., Shen, K., Yu, S. Y. 2015. AFM measurements of adhesive forces between carbonaceous particles and the substrates. Nucl Eng Des, 293: 87–96.

Zhang, Z. Y., Wu, Z. X., Wang, D. Z., Xu, Y. H., Sun, Y. L., Li, F., Dong, Y. J. 2009. Current status and technical description of Chinese 2×250MWth HTR-PM demonstration plant. Nucl Eng Des, 239: 1212–1219.

Acknowledgements

This project was supported by the National Natural Science Foundation of China (NSFC, Grant No. 51676112), the National Key R&D Program of China (Grant No. 2018YFB1900500), and the National S&T Major Project (Grant No. ZX069).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sun, Q., Hai, X., Wang, K. et al. Study of the deposition of graphite dust in the inlet passageway of intermediate heat exchanger in VHTR. Exp. Comput. Multiph. Flow 1, 29–37 (2019). https://doi.org/10.1007/s42757-019-0003-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42757-019-0003-4