Abstract

This research focuses on the extraction and characterisation of chitin and chitosan from fungal biomass, Termitomyces titanicus, by immersing it in a solution of sodium hydroxide, followed by deacetylation in a basic medium using the full two-level factorial design (22) to obtain chitosan as a residual. The obtained chitosan was characterised by basic conductimetric titration and viscometry to determine the degree of deacetylation and the average molecular weight, respectively. The extraction of chitin was carried out under the following operating conditions: particle size less than 2.5 mm; hydrolysis time of 120 min; concentration 3 M of the NaOH solution; and temperature of 100 °C. The extraction yield of chitin was 38.04%, and the degree of deacetylation of chitosan was 69.50%, an intrinsic viscosity of 0.6822 dL/g, and a viscosimetric average molecular weight of 985.88 kDa. This research therefore shows that fungus specie called T. titanicus can serve as an alternative chitin and chitosan source. In addition, the mathematical model established for deacetylation degree that, based upon the extra process time, it would be possible to increase the purity of chitosan.

Similar content being viewed by others

1 Introduction

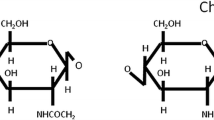

The sources of chitin are varied throughout the world arthropods (crustaceans, insects, arachnids), with more than a million species, in particular constitute an abundant source of this polymer. Chitin is present, for example, in shrimps, lobsters, crabs, the Norway lobster, squid, insects (cockroaches, ants) or algae, yeasts and fungi [18]. Chitin and its main derivative, chitosan, are the most abundant biomaterials in nature after cellulose, and have multidimensional properties due to hydroxyl groups and amines within their structure. The areas of application of chitosan are very varied, including those of water treatment, biomedical issues, cosmetics, biotechnology, and agri-food [12, 21, 24, 28, 31, 36, 39, 42]. Chitin was discovered in 1811 by the French chemist Braconnot, who isolated it from a fungus [22]. Chitin is 2-acetamido-2-deoxy-d-glucopyranose (N-acetylglucosamine) (Fig. 1) [17].

In chitin, the degree of acetylation is typically 0.90, indicating the presence of certain amine groups (as a certain amount of deacetylatikon can occur during extraction, chitin may also contain about 5–15% of amine groups) [5, 10]. Thus, the degree of N-acetylation, i.e. the ratio of 2-acetamido-2-deoxy-d-glucopyranose to the structural units of 2-amino-2-deoxy-d-glucopyranose, has a considerable impact on the solubility of chitin and the properties of the solution [34]. Chitosan is the N-deacetylated derivative of chitin with a typical degree of deacetylation (DD) of less than 0.35 whose structure is represented in the Fig. 2. It is therefore a copolymer composed of glucosamine and N-acetylglucosamine. The physical properties of chitosan depend on several parameters, such as molecular weight (from about 10,000 to 1 million Daltons), DD (from 50 to 95%), the sequence of amine groups and acetamides, and the purity of the product [28, 35].

Chitin and chitosan are produced industrially from crustacean co-products, especially shrimps and crabs. However, the choice of the raw material is related to the local activity. Some geographical areas favour other resources, such as fungal sources like mushrooms, krill or pink shrimps. Fungal chitin and chitosan have the advantage to being extracted at any time of the year, avoiding seasonal fluctuations in comparison with those produced from crustaceans; the fungal mycelia can be produced in bioreactors optimising the conditions of crops and making it at high current research interest [1, 3, 41]. For this reason, recently, various processes were implemented to extract chitin and chitosan from fungal biomass.

Several recent studies [11, 15, 19, 26, 37] show that chitin and chitosan can be extracted from different species of fungus, including Ganoderma lucidum, Agaricus sp., Pleurotus sp., Pleurotus ostreatus, Fomes fomentarius, Boletus bovinus, etc. The extraction yield of the obtained chitin varied between 7 and 43% depending on the type of fungus. In this regard, the chemical composition of a fungus in particular the crude chitin content is not the same in different varieties of mushroom, hence the yield and the quality of the extracted chitin and/or chitosan will depend on the isolation method and its chemical composition [2, 37, 38]. In the present research, we have aimed to evaluate the potential of using mushrooms of Haut-Katanga—in particular Termitomyces titanicus as a source of chitin and chitosan. The study objective is to determine the extraction yield of chitin by proceeding essentially by a deproteinization in alkaline medium to remove proteins and carbohydrates; and the physicochemical properties of chitosan—particularly the degree of deacetylation using the full two-level factorial design (22) in order to have a large area of the factor space while providing useful information for a limited number of factor tests whose purpose is to determine the main trends of factors for use as reference for future experiments; and finally intrinsic viscosity and molecular weight from the equation of Mark, Haouwink and Sakurada for subsequent application.

Thus, this paper provides some information on characterisation of T. titanicus, the influence of deproteinisation rate on the extraction yield of chitin from this specie of fungi, and the use of the basic conductimetric titration method and reduced and inherent viscosity respectively to determine the degree of deacetylation and the intrinsic viscosity of extracted chitosan.

2 Materials and methods

2.1 Material

2.1.1 Origin of biomass

The biomass used is a species of fungi, T. titanicus, which was collected in the bush around Kamawese village along the Likasi road, about 35 km from the city of Lubumbashi (Fig. 3).

The species appears early and fruits no later than November or December. It is highly prized because of its weight which can reach 3–4 kg, its pronounced taste, and its large size. It is consumed throughout the Zambezian region, and especially in Haut-Katanga. The sporophores are gigantic, and are sometimes gregarious on high termite mounds. This mushroom has a hat 50 to 100 cm in diameter. When young and fleshy, it presents a hemispherical and convex spread form and largely umbonate in the center; dry it has a granular-tomentose and brown-greyish coating [8].

2.1.2 Sampling and sample preparation

Samples of fungi of the same species were collected in two campaigns at two different sites on and nearby termite mounds. They were detached from the soil manually from their sporophores, cut into small fragments, dried in an oven model UN30plus TwinDISPLAY made by Memmert GmbH+Co. KG in federal republic of Germany, and crushed and sieved to a particle size less than 2.5 mm. The mushroom powder obtained was approximately 4 kg (dry weight) and was homogenised in a jar and then stored in the laboratory in a desiccator to preserve moisture.

2.1.3 Solutions and reagents

The main solutions and reagents used are 97% purity sodium hydroxide pellets, 37% hydrochloric acid solutions, 96% sulfuric acid, 96% acetic acid, and 96% ethanol purity.

2.2 Methods

2.2.1 Characterisation of biomass

Ash, lipid, crude protein and moisture contents were determined by the reference methods [4]. The nitrogen conversion factor used to calculate the protein content was 4.38 [7]. The carbohydrate content was calculated using Eq. (1).

2.2.2 Extraction of chitin and chitosan

The method of extraction of chitin and chitosan by chemical means implemented is to deproteinise the biomass followed by deacetylation of chitin to obtain chitosan as a residue. The last step is the purification of the obtained chitosan [23, 30].

This extraction was carried out by immersing the dried and ground fungus powder at a particle size of less than 2.5 mm, successively in 1 M, 2 M, 3 M and 4 M NaOH solutions, at a solute–solvent ratio of 1:40 (g/mL), for 120 min of hydrolysis at 100 °C in waterbath model WNB7 made by Memmert in federal republic of Germany. The discolouration was carried out by washing several times with 96% ethanol and distilled water.

2.2.3 Estimate of chitin content

The T. titanicus powder was hydrolysed in 6 N HCl solution at 80 °C for 16 h. The chitin content (M: mass of chitin) in the sample can be calculated from the glucosamine content (m: mass of glucosamine units) obtained, assuming that all units of the biopolymer were acetylated according to Eq. (2); with 203 the molecular weight of anhydrous acetylglucosamine and 179 the weight of glucosamine in g/mol [25, 29].

2.2.4 Determination of the degree of deacetylation

The conversion of fungal chitin into chitosan has been optimised via the full two-level factorial design (22), in order to have necessary information with a limited number of tests per factor. The limits of the field of study, which are the minimum and maximum values of the studied factors (concentration of NaOH and time of deacetylation), are denoted respectively by (− 1) and (+ 1) as indicated in Table 1. This operation was performed at a constant temperature of 100 °C according to a solute–solvent ratio of 1:10 (g/mL) (Table 1). After deacetylation operation, the obtain residual was washed several times with distill water until a neutral pH and dissolved in 2% acetic acid. NaOH solution 1 M was added to the mixture in order to collect chitosan as a precipitate.

The basic conductimetric assay was used to determine the degree of deacetylation (DD) of chitosan obtained, because it is a simple, less expensive, fair and accurate method for determining the latter’s DD [40]. This analysis was done in triplicate by solubilising 150 mg of each sample obtained in 10 mL of 0.1 N HCl solution, and then adjusting the volume of the solution to be titrated to 200 mL with distilled water. The titration of each solution was carried out with a solution of 0.1 N NaOH, while measuring the conductivity of the solution to be titrated after each addition of the NaOH solution. The chitosan DD was calculated using Eq. (3):

m represents the weight of the sample of chitosan (mg); V1 and V2 represent the equivalent volumes of sodium hydroxide solutions corresponding to the points of deviation; 203 (g/mol) is the molecular weight of the acetylated monomer; 42 (g/mol) is the difference between the molecular weight of the acetylated monomer and the molecular weight of the deacetylated monomer; and N represents the value of the normality of the basic solution.

2.2.5 Determination of the average molecular weight

The molecular weight of the deacetylated chitin was calculated from its intrinsic viscosity ([η]) by applying Eq. (4) of Mark, Haouwink and Sakurada, where K and a are constants and Mv the molecular weight in Daltons [13]. Referring to the work of Rao [32], who used the same solvent (1% acetic acid solution) at a temperature of 30 °C, we adopted the value 0.72 for a and 4.74.10−5 dL/g for K, which are constants for a given solvent–solute system [16].

The intrinsic viscosity of chitosan is determined experimentally by capillary viscometry. In this research, we used an Ostwald viscometer. The method is based on the measurement of the flow time (t0) of the same volume of solvent (consisting of 1% acetic acid) or chitosan solution (t) contained between the two points (lines) marked on the viscometer using a chronometer. The specific viscosity (ηsp) is defined by Eq. (5).

Dividing this value by the concentration of the chitosan solution (Ci) in g/dL, gives the reduced viscosity (ηred) defined by Eq. (6):

Thus, for different concentrations of chitosan (0.01, 0.025, 0.05, 0.075 and 0.1 g/dL) different reduced viscosity values are obtained. The plotting of the reduced viscosities as a function of the concentrations, gives rise to a line whose ordinate at the origin is equal to the intrinsic viscosity.

The intrinsic viscosity can be determined otherwise by means of the inherent viscosity (ηinh) obtained from the relative viscosity (ηrel), defined by Eq. (7):

2.2.6 Statistical analyses

The results obtained for the degree of deacetylation were statistically processed using Minitab 18 software. This enabled us to determine the effect of the factors studied on the response using the linear regression equation and to perform the analysis of the variance at a threshold of 5% rejection.

3 Results and discussion

3.1 Characterisation of biomass

Preliminary analysis of the main constituents of biomass gave the results presented in Table 2. These results are similar to those estimated by Pavel [27] for a large variety of fungi. The dry matter is about 17.26%. Carbohydrates (especially β-glucans and about 13.53% chitin) and crude protein are the main components of mushroom dry matter.

The ash content obtained is relatively low compared to that found in the shells of crustaceans (crabs and shrimp), which is 20 to 40% depending on the crustacean species [14, 33]. As a result, minerals are not bound to the chitin matrix in T. titanicus and most fungi in general, as is the case in crustacean shells; hence the demineralisation operation is not often required.

3.2 Yield of chitin extraction

The average extraction yield of chitin was 38.04% with a corresponding deproteinisation rate of 87.03% (Table 3).

Figure 4 shows the evolution of the extraction yield of chitin and the corresponding deproteinisation rate by varying the concentration of the sodium hydroxide solution.

This graph shows a significant elimination of the crude proteins during the treatment with sodium hydroxide and the plateau reached by the two curves around a concentration of 3 M NaOH. It appears that the crude chitin is composed of carbohydrates and residual proteins and is intermingled mainly with β-glucans and this could be explained by a large difference between the rate of deproteinisation and the chitin extraction yield. This would be in agreement with the results found by Tao [38] for the tests carried out on Agaricus bisporus, which were obtained after extraction of chitosan 43.84% of glucosamine and 17.92% of β-glucans.

This yield is similar to that obtained by Ospina et al. [26] from Ganoderma lucidum and by Marikani et al. [19] from Agaricus sp., Pleurotus sp. and Ganoderma sp., which was about 41% and 41.3% respectively.

3.3 Deacetylation degree of chitosan

Table 4 presents the results of the experimental tests using as a factor the concentration of NaOH and the deacetylation time. The best degree of deacetylation was 69.50%, value obtained in Test No. 2.

Figure 5 illustrates the corresponding basic conductimetric titration curve and Fig. 6 shows the other three titration curves.

The conductimetric titration curve of chitosan with the two points of deviation: V1 corresponds to the amount of HCl in excess; the difference in volume (V2 − V1) of NaOH between these two points corresponds to the amount of HCl necessary to dissolve the chitosan, and to transform the NH2 groups into NH3−

This DD value is comparatively lower than those found by other authors. For example, Ming-Tsung and Jeng-Leun [20] used three different fading methods, which resulted in a DD of 98.21%. Nevertheless, this approach is similar to those found by Tao [38] for the tests carried out on Aspergillus niger for 30 min of deproteinisation and 6 h of purification (extraction in acetic acid at 2%), and that of 72.51% obtained by Dhanashree and Basavaraj [9] for chitosan extracted from Rhizopus oryzae by separating at each step of the process the insoluble material (chitin and chitosan) from the liquid by centrifugation. The values close of commercial chitosan have been obtained by several authors because of intense purification of chitosan, which explains the difference between our value of DD and commercial chitosan whose value is between 95 and 98%.

3.4 Statistical analyses

Equation (8) presents the model of linear regression of DD as a function of the concentration of NaOH and time after elimination of the interaction coefficient, which are the least significant. The R2 of this model is 98.06%, close to 100%, indicating that the percentage change in the response explained by this model is adjusted to the data:

The observations that can be drawn from this model establish that the time of the deacetylation operation has a greater contribution to the increase of the DD of chitosan compared to the concentration of NaOH. By proceeding in successive stages during sufficiently long-time intervals, it would be possible to increase the purity of chitosan—in other words to increase the degree of deacetylation. The analysis of variance for chitosan DD shows that for experiments using the full factorial design at a rejection threshold of 0.05, no factor of two has a statistically significant effect on the total variability of DD. However, the complete two-level factorial design used allowed the determination of the main trends that can be used as references for other experiments.

3.5 Determination of the average molecular weight

Figure 7 shows the evolution of the reduced and inherent viscosity of chitosan as a function of concentration of chitosan.

Table 5 present the result of linear fit of reduced and inherent viscosity. By replacing the value of the intrinsic viscosity (the intercept value) in Eq. (4) of Mark, Haouwink and Sakurada, we obtain the viscosimetric average molecular weight which is about 985.88 kDa.

The value of R2 close to 1 show that the linear fit or mathematical model obtained is in adequation with the experimental data observed. The value of the molecular weight of chitosan depends closely on the extraction process, because it can induce depolymerisation of the macromolecular chains and/or degradation during the extraction. The macromolecular chains of chitosan generally have a molecular weight of 100 to 1500 kDa [6]. These weights determine the desired application for chitosan. Compared with other samples of chitosan obtained from other fungal species, and, in particular, marine sources (crustaceans), the fungal chitosan obtained has a relatively high molecular weight. For example, Dhanashree and Basavaraj [9] obtained a molecular weight of the fungal chitosan extracted from Rhizopus oryzae of 350 kDa—which was greater than the standard chitosan used, but lower than that found in this study. This is probably due to the presence of impurities including β-glucans, because the DD, the intrinsic viscosity and the molecular weight of chitosan are closely related properties.

Due to its degree of deacetylation and its molecular weight, this fungal chitosan can be used unambiguously in the agri-food sector as a fertilizer or as a bio-adsorbent in the wastewater treatment sector—or any other sector in which a pure or ultra-pure product is not required.

4 Conclusion

Chitin and chitosan have been extracted from fungal biomass, the T. titanicus. The method developed for this purpose consisted of a first step of deproteinisation and deacetylation of chitin and a second step of purification of chitosan. This chemical process used for the extraction of chitin made it possible to obtain a chitin extraction yield of 38.04% this confirms that the T. titanicus can be used as an alternative source of fungal chitosan. The chitosan obtained had a degree of deacetylation of 69.50%, this value is lower than that of commercial chitosan produced from crustaceans; however, it is close to some DD values obtained from other fungi.

Although there are many publications on obtaining chitin and chitosan from fungal sources, nothing has been found concerning the extraction of chitin from T. titanicus in the literature. Future research should be oriented towards optimizing the operating conditions on purification of chitosan. This should be done in several successive steps in order to increase the purity of chitosan. This work can therefore be useful for new investigations for the application of chitosan in different fields.

References

Abdel-Gawad K, Hifney A, Fawzy M, Gomaa M (2017) Technology optimization of chitosan production from Aspergillus niger biomass and its functional activities. Food Hydrocoll 63:593–601

Alona O, Asier M Salaberriab, Rita S, Gintautas S, Murat K, Jalel L, Vykintas B (2019) Physicochemical and in vitro cytotoxic properties of chitosan from mushroom species (Boletus bovinus and Laccaria laccata). Carbohydr Polym 221:1–9

Alsaggaf MS, Moussa SH, Tayel AA (2017) Application of fungal chitosan incorporated with pomegranate peel extract as edible coating for microbiological, chemical and sensorial quality enhancement of Nile tilapia fillets. Int J Biol Macromol 99:499–505

AOAC (1980) Official methods of analyses of the association of official analytical chemists. Association of Official Analytical Chemists, Washington, DC

Campana-Filho SP, De Britto D, Curti E, Abreu FR, Cardoso MB, Battisti MV (2007) Extraction, structures and properties of α- and β-chitin. Quim Nova 30:644–650

Crini G, Guibal E, Morcellet M (2009) Chitine et chitosane. Préparation, propriétés et principales applications. du biopolymère à application, presses universitaires de Franche-Comté, pp 19–54

Crisan EV, Sands A (1978) Edible mushrooms: nutritional value. In: Chang ST, Hayes WA (eds) The biology and cultivation of edible mushrooms. Academic Press, New York, pp 137–165

De Kessel A, Kasongo B, Degreef J. (2017) Champignons comestibles du Haut-Katanga (R.D. Congo). ABC-Taxa vol. 17. Support de la coopération Belge au développement. ISBN 9789082179828, pp 232–235

Dhanashree BG, Basavaraj SH (2018) Two-phase extraction, characterization, and biological evaluation of chitin and chitosan from Rhizopus oryzae. J Appl Pharm Sci 8(11):116–122

Dong Y, Xu C, Wang J, Wu Y, Wang M, Ruan Y (2002) Influence of degree of deacetylation on critical concentration of chitosan/dichloroacetic acid liquid-crystalline solution. Appl Polym Sci 83:1204–1208

Ekaterina B, Roman B, Ekaterina L, Leonid S, Jana C, Ivan J, Pavel K, Andriy S (2019) Polysaccharides from basidiocarps of cultivating mushroom Pleurotus ostreatus: isolation and structural characterization. Molecules 24(15):2740. https://doi.org/10.3390/molecules24152740

GIA (2010) Chitine et chitosane, Rapport de Gestion Stratégique Global. Global Industry Analysts, MCP-2039, p 230

IUPAC: International Union of Pure Applied Chemistry (1991) Compendium of macromolecular nomenclature. Blackwell Scientific Publications, Oxford

Jung WJ, Jo GH, Kuk JH, Kim KY, Park RD (2005) Extraction of chitin from red crab shell waste by cofermentation with Lactobacillus paraccasei subsp. Tolerans KCTC-3074 and Serratia marcescens FS-3. Appl Microbiol Biotechnol 71(2):23–237

Kalutharage NK, Rathnasinghe DL (2019) A study of chitosan and glucosamine isolated from Sri Lankan local mushroom Schizophyllum commune and oyster mushroom (Pleurotus ostreatus). Mater Today Proc. https://doi.org/10.1016/j.matpr.2019.07.713

Kassai MR (2010) Determination of the degree of N-acetylation for chitin and chitosan by various NMR spectroscopy techniques. A review. Carbohydr Polym 79:801–810

Khor E (2001) Chitin: fulfilling a biomaterials promise. Elsevier Science, Amsterdam

Kurita K (2001) Controlled functionalization of the polycaccharide chitin. Prog Polym Sci 26:1921–1971

Marikani K, Maliga NK, Rajarathianam K, Ranjit S (2010) Production and characterization of mushroom chitosan under solid-state fermentation conditions. Adv Biol Res 4(1):10–13

Ming-Tsung Y, Jeng-Leun M (2006) Preparation of fungal chitin and chitosan from shiitake stipes. Fung Sci 21(1–2):1–12

Morin-Crini N, Lichtfouse E, Giangiacomo T, Grégorio C (2019) Applications of chitosan in food, pharmaceuticals, medicine, cosmetics, agriculture, textiles, pulp and paper, biotechnology, and environmental chemistry. Environ Chem Lett 17:1667–1692. https://doi.org/10.1007/s10311-019-00904-x

Muzzarelli RAA, Jeuniaux C, Gooday GW (1986) Chitin in nature and technology. Plenum Publishing Corporation, New York

Muzzarelli RA, Ilari P, Tarsi R (1994) Chitosan from Absidia coerula. Carbohydr Polym 25:45–50

Nguyen LM, Nguyen TTH (2019) Enhanced heavy metals biosorption using chemically modified chitosan coated microwave activated sugarcane baggage ash composite biosorbents. SN Appl Sci 1:1555. https://doi.org/10.1007/s42452-019-1607-9

Novikov VY (1996) Kinetics of formation of D(+)-glucosamine by acid hydrolysis of chitin. Russ J Appl Chem 72(1):156–161

Ospina S, Ramirez DA, Fernando D, Zapata P (2014) Comparison of extraction methods of chitin from Ganoderma lucidum mushroom obtained in submerged culture. Biomed Res Int 2012: Article ID 169071

Pavel K (2012) Chemical composition and nutritional value of European species of wild growing mushrooms. In: Andres S, Baumann N (eds) Mushrooms: properties and nutrition. Nova Science Publishers, Inc., Hauppauge, p 126

Pillai CKS, Willi P, Chandra PS (2009) Chitin and chitosan polymers: chemistry, solubility and fiber formation. Prog Polym Sci 34:641–678

Plassard SC, Mousain GD, Salsac EL (1982) Estimation of mycelial growth of basidiomycetes by means of chitin determination. Photochemistry 21(2):345–348

Pochanavanich P, Suntornsuk W (2002) Fungal chitosan production and its characterization. Lett Appl Microbiol 19:17–21

Rahim M, Mas Haris MRH (2019) Chromium (VI) removal from neutral aqueous media using banana trunk fibers (BTF)-reinforced chitosan-based film, in comparison with BTF, chitosan, chitin and activated carbon. SN Appl Sci 1:1180. https://doi.org/10.1007/s42452-019-1206-9

Rao DG (1993) Studies on viscosity–molecular weight relationship of chitosan solutions. J Food Sci Technol 30(1):66–67

Rao MS, Munoz J, Stevens WF (2000) Critical factors in chitin production by fermentation of shrimp biowaste. Appl Microbiol Biotechnol 54(6):808–813

Rinaudo M (2006) Chitin and chitosan: properties and applications. Prog Polym Sci 31:603–632

Rinaudo M (2008) Main properties and current applications of some polysaccharides as biomaterials. Polym Int 57:397–430

Shruti S, Punita U, Khosa MA, Tony M, Abdus S, Sandra S, Aman U (2018) Overview of wastewater treatment methods with special focus on biopolymer chitin-chitosan. Int J Biol Macromol. https://doi.org/10.1016/j.ijbiomac.2018.10.089

Stephanie B, Mihkel V, Andres K, James M (2019) Properties of chitin extracted from Estonian mushrooms. Proc Estn Acad Sci 68(3):333–336

Tao W (2004) Production and characterization of fungal chitin and chitosan. Master’s thesis, University of Tennessee

Terence Y (2016) Application of chitosan in the treatment of wastewater from agricultural sources. Electronic theses and dissertations, University of Windsor, pp 17–19

Yu GE, Morin FG, Nobes GAR, Marchessault RH (1999) Degree of acetylation of chitin and extent of grafting PHB on chitosan determined by solid state N-15 MMR. Macromolecules 33:518–520

Zapata PA, Rojas DF, Atehortua L (2012) Production of biomass, polysaccharides, dan ganoderic acid using non-conventional carbon sources mushroom, Ganodrma lucidum (W.Curt.: Fr.) P. Karst. (higher basidiomycetes). Int J Med Mushrooms 12(2):197–203

Zhaojun B, Batia H, Roi R, Ofer D, Cristina B, Tara M, Victor R, Elena P (2018) Efficient production of fungal chitosan utilizing an advanced freeze-thawing method; quality and activity studies. Food Hydrocoll 81:380–388

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

John Kasongo, K., Tubadi, D.J., Bampole, L.D. et al. Extraction and characterization of chitin and chitosan from Termitomyces titanicus. SN Appl. Sci. 2, 406 (2020). https://doi.org/10.1007/s42452-020-2186-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-020-2186-5