Abstract

There is a need for friendly and affordable wound dressing materials capable of uptaking and releasing active clinical agents. Proper combinations of materials that could quickly release antibiotics at the beginning, then slow and controlled release with time would make excellent materials for wound care management. In this study, cotton handwoven fabric hydroxyapatite (derived from coralline skeletons) polylactic acid composites were developed. The developed composites were characterized in terms of their physical and mechanical properties. Also, the in vitro drug release profiles for the developed composites were established. Bacteria efficacy of natural antimicrobial agents loaded composites against gram-positive bacteria Staphylococcus aureus (S. aureus) was also studied. The results suggested that the hand-weaving method has the potential to control the porosity of the fabric for different applications. Woven fabric with 1 mm pore sizes is suggested to have better particle uptake properties and moderate mechanical and physical properties suitable for wound dressing applications. Particle embedment capacity (w/w %) seemed to increase as the fabric pore sizes increases. On the other hand fabric with 1 mm pore sizes uptakes the highest amount of particles (0.174 g). A combination of coralline derived hydroxyapatite particles with cotton fabric suggested controlling the drug release rate by 30% compared with the fabric without the particles, appropriate for prolonged drug release applications. The released drug and natural antimicrobial agents from the developed composites suggested inhibiting microbial growth in which honey performed close to a clinical antibiotic. It was recommended to conduct an in vivo study for the developed composite.

Similar content being viewed by others

1 Introduction

Wound healing involves a complex cascade of events until the skin is completely restored. The human body is naturally designed to coordinate this process through immune systems, hormones, and different cells by stimulating self-tissue regeneration and healing [1]. However, this process is slow and if compromised by either age or other health complications such as diseases, it may lead to chronic wounds [2]. Different wound treatments are available depending on the types of wounds but the most common medical treatment is through the application of wound dressing. Low-cost textile materials such as cotton cellulose fibrous have been commonly used for wound dressing management. However, they tend to stick on the wound bed and cause pain during change of dressing. They can also cause skin maceration and microbial growth on the wound. Different strategies have been proposed to improve cotton as wound dressing materials such as surface functionalization [3,4,5] or combination with other materials to make composites [1, 6]. These modifications are suggested to improve drug loading and delivery capacity, controlled drug release rate, maintain a moist environment around the wound, and enhance comfort.

In our last work [1] we showed that composite materials from cotton fabric and polylactic acid suggested having improved properties such as antibiotic delivery, mechanical strength, and an enhanced healing process while preventing bacterial infection. The reviewed literature shows that cotton fabric coated with different materials such as hydrocolloids [7], hydrogels [8, 9], chitosan [7, 10], or silver nanoparticles [5] displays an improved wound dressing property. Proper combinations of biodegradable materials that could quick-release antibiotics at the beginning then slow and controlled release with time, would make excellent material for wound care management. Water uptake of cellulose fibres is also believed to be improved when the surface modification is done on the fibres. This avoids wound dehydration, which may lead to materials anchored on the wound surface and cause pain and removal of newly regenerated tissue on the wound during change of dressing.

The use and application of extracts with antimicrobial activity from natural materials have been used for wound care management by either incorporating them into the wound dressing materials or directly on the wound site. Essential oils have been reported to inhibit the growth of E. coli when incorporated into cellulose-based wound dressing materials [11]. It has been suggested that the incorporation of a small amount of essential oil like 1% can inhibit the growth of E. coli. Honey has been used for centuries in wound healing and management. With very effective clinical options available in the market for wound management, honey may still be considered for healing certain wounds. Honey has a unique acidic pH balance that promotes healing and the osmotic effects, which together with the presence of hydrogen peroxide suggested imparting antimicrobial effects [12]. Studies show that honey provides better healing of burn wounds and infected post-surgery wounds than many conventional options [13]. Curcumin has been studied as a potential antimicrobial agent for wound care management. Pramanik and co-workers reported that curcumin loaded in blended film displayed markedly enhanced wound healing and strong bactericidal activity against a gram-positive strain [14]. The combination of honey and turmeric in the treatment of wounds is not well studied. The demand for wound dressing materials capable of releasing antimicrobial and other compounds that would enhance the wound-healing process in a controlled manner is increasing. A clinical study on the use of honey-coated bandages for the treatment of malignant wounds is reported to have a similar effect to silver nanoparticle-coated bandages [15].

Coralline-hydroxyapatites derived from marine skeletons have been used in tissue engineering applications. The unique architecture of coralline skeletons and their interconnected porous structure potential for drug uptake and release have attracted researchers and clinicians on the use of these materials for biomedical applications [16,17,18]. Developing wound dressing materials using coralline hydroxyapatite as one of the components will enhance the controlled release of an antimicrobial agent and therefore prevent bacterial infection for certain wounds that normally take time to heal. Cotton cellulose fibrous is limited in its capacity to uptake drug and the release rate is fast and difficult to control. To enhance controlled release, cotton fibrous materials have been coated with a degradable polymer to slowly release the drug and the results are promising. The drawback of this approach is the thick layer of polymer you have to use for prolonged-release which results in it taking a long time after the bust release before the therapeutic drug concentration is released. This is because polymer has to degrade to the point where the drug on the surface of the cotton fibre can diffuse towards the polymer surfaces [19]. During this time wounds could potentially be infected because there is only a small concentration of antibiotics being released. The ideal approach would be loading drugs into micro-particles that could be embedded into cotton cellulose fibrous and covered with a thin film of degradable polymer. This would ensure the controlled release at all times when the wound is dressed with this material.

To the best of our knowledge, there is very little information in the literature regarding this approach. The research is focused on developing cotton woven fabric—coralline hydroxyapatite polylactic acid polymer composites as a drug carrier for wound dressing materials. Also, the developed materials were tested for the uptake and release of the natural antimicrobial agents such as honey and curcumin in comparison with clinical antibiotics against Staphylococcus aureus.

2 Materials and methods

2.1 Materials

The Upendo Honey Company in Tanzania supplied organic bee honey (Colour—dark colour; pH = 3.76 ± 0.1; sugar content = 74.5 g/100 g; hydroxymethyl furfural (HMF) = 25.4 mg/kg) originally from KIbondo, Kigoma, Tanzania, processed, and commercially packed. Curcumin was bought from the local market. Streptomycin sulfate (potency: ≥ 720 I.U. per mg (dried basis) and amoxicillin (potency: ≥ 90 μg per mg), were bought from Sigma Kenya. The 21st Century Textile Company in Tanzania kindly donated the cotton yarns. Coralline skeletons were obtained from coral reefs in Pemba’s coast, Zanzibar. Polylactic acid (PLA) 3052D (specific gravity = 1.24, Tg = 55–60 °C, MP = 200 °C) with Mw = 75,000 g/mol, was obtained from Nature Works LLC Australia. Bacteria media, Mueller–Hinton Agar and Chloroform with a ≥ 99% assay were bought from local suppliers. Bacteria strain Staphylococcus aureus ATCC 25923 was used in the experiment. All chemicals used were analytical grade.

2.2 Handweaving technique

Cotton yarns of count 30 tex were used to develop a woven fabric without modification. A hand-weaving machine from a local handweaver, the Bantu Kikoi Shop located in Dar es Salaam developed the fabric. During the weaving process, the yarns in the longitudinal direction which acted as the warp yarns were inserted on the beam followed by the yarns in the horizontal direction which served as the weft yarns. The weaving process was designed to control the porosity of the fabric and for this case 0.5 mm pore size fabric of 1.5 m length and 60 cm wide was developed. The other pore sizes, 1 mm and 1.5 mm were developed from 0.5 mm pore size fabric by pulling out yarns in the weft direction.

2.3 Coral conversion and embedment into fabric

2.3.1 Coral conversion: Mechano-chemical technique

Coral skeletons were crushed then cleaned with 2% (v/v) NaClO, dried in an oven at 100 °C overnight and then ground in an aluminium oxide ball mill for 3 h, then sieved and stored at room temperature. Mechano-chemical conversion of coralline to hydroxyapatite (HAp) was carried out as described in [20]. Coral skeletons contain more than 99% CaCO3 which can easily be converted into hydroxyapatite. Briefly, the required amount of NH3H2PO4, to obtain stoichiometric HAp was dissolved in 25 ml of distilled water and then added slowly (dropwise), to 3 g of milled coral powder suspended in a cleaned flask with 150 ml distilled water at 80 °C on a temperature controlled hot plate with a magnetic stirrer. The stirring rate was 200 rpm and the temperature was kept at 80 °C for 24 h. Samples were taken from the beginning of the reaction after every 30 min for 2.5 h for FTIR analysis. After conversion samples were calcined at 700 °C for 2 h.

2.3.2 Fourier transform infrared spectroscopy (FTIR)

The conversion of coral to hydroxyapatite was monitored and confirmed with FTIR. FTIR spectra were collected using a Bruker, Vector 22 FTIR Spectrometer (Bruker Corporation, Massachusetts, USA) in the range 4000–400 cm−1. Samples were ground in a mortar and thoroughly mixed with dried KBr (FTIR Grade). For the analyses, 3 mg was ground with 300 mg of KBr and pressed into a pellet (Carver press).

2.4 Antibiotic susceptibility

2.4.1 Media preparation

A solid agar medium for Staphylococcus aureus (S. aureus) was prepared by thoroughly dissolving 38 g of Mueller–Hinton Agar powder in 1 L of distilled water on a hot plate assisted with frequent stirring until the medium was completely dissolved. The solution was then autoclaved to sterilize (121 °C, liquid cycle) and cooled at room temperature. Then the cooled Mueller–Hinton Agar was poured into sterile Petri dishes on a horizontal level surface to give uniform depth. After the agar was solidified, the plates were stored at 4 °C.

2.4.2 Bacterial strains and disc assay study

S. aureus (ATCC 25923) was cultured overnight in a Tryptic Soy Broth (TSB) medium in a shaking incubator at 37 °C under anaerobic conditions. This was then diluted 1:100 into TSB and used in the disc assay experiments. Then 1.5 mL of the cell suspensions were inoculated into disc plates with solid agar. Triplicate samples of disc plates for each honey-turmeric ratios were used in the experiments. Cotton fabric samples were padded into honey-turmeric ratios while the control was padded into Streptomycin sulfate solution. Honey used in this experiment was not diluted but used directly. The dosage ratio was based on the 15 mL of honey, which has been described in [21] as the initial dosage for wound treatment. Its physico-chemical properties mentioned in 2.1 are consistent with tropical honey standards [22]. Then the padded samples were placed on top of the medium. The plates were sealed with sterile breathable film and incubated at 37 °C for 24 h.

2.4.3 Embedment of HAp into woven cotton fabric

The embedment was done by mixing 6 g of coralline hydroxyapatite powder in 20 ml of HCL to make 30 g/cm3 concentration of ceramic in HCL. Then each 1 ml of a suspension was mixed with 10 ml of ethanol to make a nano solution thus the concentration of each solution contained 0.3 g of hydroxyapatite. After obtaining the solution, the sterile fabric samples (sterilized in autoclave (121 °C, liquid cycle) and cooled at room temperature) were then soaked for 1 h to allow the embedment of the hydroxyapatite. Then the fabric samples were dried at room temperature for 24 h.

2.5 In-vitro drug loading and release from HAp-embedded cotton fabric

For the drug dissolution study, HAp particles were loaded with 10% (w/w) amoxicillin in a Rotary evaporator (60 °C at 60 rpm with maximum vacuum and 10 °C cooling temperature) and then dried in an oven at 60 °C overnight before being embedded into cotton fabric samples of 6 cm × 5 cm as described in 2.3.3. The drug loading efficiency to HAp particle has been reported in our previous publication [17]. All samples were thinly coated with a biodegradable polymer (Polylactic acid) in polylactic acid-chloroform solutions with different concentrations (0.01 g/mL, 0.03 g/mL and 0.06 g/mL) by using a dip coat technique and then samples were put in Petri dishes to dry in a fume cabinet for 24 h. Drug dissolution was studied under SINK condition in a PBS (0.1 M, pH 7.4) at 37 ± 0.1 °C in a temperature-controlled oil bath shaker running at a constant speed of 100 rpm. 2 ml of each sample was taken every day for a consecutive 14 days and the release concentration was monitored by UV–vis double beam spectrophotometer. On the other hand apart from clinical antibiotic, other natural antimicrobial agents (honey and turmeric) were loaded into the developed fabric at different ratios to establish their efficacy against bacteria.

2.6 Mechanical properties of HAp embedded cotton fabric

Tensile testing of the cotton fabric embedded with HAp was performed in a universal tensile testing machine (Instron 5566, Series IX Automated Materials System 8.25.00) with a crosshead speed of 100 mm/min and the load cell of 10 kN according to Tanzania Standards (TZS 22:1979). A total of five specimens for each sample were tested with a gauge length of 100 mm and a width of 50 mm. Deformation was followed with Blue Hill 3 software version 3.41.

3 Results and discussions

3.1 Fabric physical properties

The obtained woven fabric was characterized in terms of its physical properties based on the ASTM D5446-08(2013) standard and presented in Table 1. Figure 1 shows the fabric with different pore sizes before and after bleaching. It was observed that fabrics have a similar number of warps but different number of wefts. This is consistent with fabric density, which decreases as the pore size increases. The difference in weft and warp numbers also indicates the anisotropic behaviour of these fabrics in terms of mechanical strength. These properties are consistent with the fabric pore size.

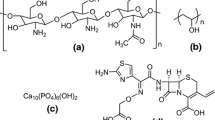

3.2 FTIR of the converted coral

Figure 2 displays IR shifts of HAp derived coral from the mechano-chemical method under basic condition. The results suggest that HAp obtained from this technique has FTIR shifts consistent with the ones reported in the literature [23]. The characteristic bands of the functional groups of HAp are seen in Fig. 2. Characteristic vibrations of PO4 tetrahedral such as v1, v4, and v3 occurred at 962 cm−1, 559 cm−1, and 1021 cm−1 respectively. The absorption maximum of CO3 group at 854 cm−1 and 1444 cm−1 can also suggest AB-type PO4 and OH group’s substitution in the structure of HAp. The spectra also suggested that the conversion starts immediately after the ammonium hydrogen phosphate is mixed with the coral. It was previously suggested the reaction mechanism can be classified as the solid-state topotactic ion-exchange reaction mechanism [24].

3.3 HAp particle embedment capacity of cotton fabric and the effect in mechanical properties

Particle uptake capacity of cotton fabric in this study is of importance because it correlates with the drug loading capacity. The effect of mechanical properties with respect to the amount of particles loaded is presented in Fig. 3. Most of the particles were expected to stick on the surface of the fabric and with respect to pore size fabric with 1 mm pore size up took most of HAp particles followed by fabrics with 1.5 mm and 0.5 mm pore sizes respectively. Fabrics with pore sizes larger than 0.5 mm are suggested that their yarns are far apart enough for the particles to embed around the individual yarns. On the other hand fabric with 0.5 mm and less would be more accessible on the sides of the fabric and not around the individual yarns, hence fewer particles were embedded.

On the mechanical properties, the results suggested that the tensile strength of the fabric decreases with the increase of the amount of particles embedded. It is envisaged that particles penetrate and make a small separation of single fibres within the yarn and increase the yarn twist, which weakens the mechanical strength of the fabric. The particles seem to lower the mechanical strength of fabrics between 31 and 44%. However, the resulting products have enough strength to be useful in the area of less load-bearing applications such as wound dressing. In considering the weight of fabric with respect to the weight of particle loaded, uptake capacities are shown to be 15%, 23% and 27% for fabrics with pore size 0.5 mm, 1 mm and 1.5 mm respectively, see Fig. 4. In drug loading the amount of particle loaded would be of more interest than the percentage loading capacity. Therefore, in the in vitro drug dissolution study, a fabric with a 1 mm pore size was used.

Percentage elongation of the fabrics after particle embedment seemed to increase by 167%, 133% and 130% for fabric with pore size 0.5 mm, 1 mm, and 1.5 mm respectively, see Fig. 5. This trend is consistent with the percentage particle loading capacity of these fabrics (Fig. 4), the lower the percentage loading the higher the percentage elongation of the respective fabric. This could be described as the effect of nanoparticle interference with the fibre bundle (yarns) in which particles get in between single fibres and improve how much fibre can slide on top of another fibre.

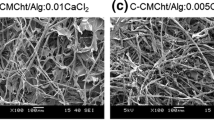

3.4 In-vitro study of drug dissolution from HAp loaded cotton fabric-PLA composites

Figure 6 shows the release profiles of cotton fabric bioceramic polymer composites of a 1 mm pore size coated with different polymer concentrations. It has to be noted that only samples loaded with clinical antibiotic drug were used in this study. Samples loaded with natural antimicrobial agent were subjected to he disc assay study, reported in Sect. 3.5. The pore size was chosen based on the highest amount of HAp uptake by the fabrics. Since the drug was loaded into the particles the higher the amount of particles the higher the amount of drug was loaded into the fabric. It is believed that the drug not only loaded into meso and nano pores of the HAp particles but also the whole surface of the particles are coated with the drug with similar mechanisms reported in the literature [25, 26]. The release profiles revealed that the amount of polymer added a control mechanism on the drug release rate. Naturally, HAp derived from coralline skeletons has the ability to control the release rate due to the presence of meso and nanopores [18].

Practically, there are several factors that could influence the drug release from these materials such as the type of drug (hydrophilic, hydrophobic, small or big molecules etc.), conditions during drug dissolution (ionic, acidic, basic, temperature etc.), preparation method, geometry of the drug-releasing materials, to mention just a few. Generally, the release of drugs from most of the materials is mainly by diffusion, driven by other factors such as biodegradability rate (in case of biodegradable materials), drug solubility behaviour together with other factors mentioned earlier on [27]. In concluding, in this study one assumption was made, that the drug particles or rather HAp particles loaded with the drug are dispersed randomly throughout the fabric and the probability of finding the particle at any point in the fabric surface is constant at all positions. The release profiles showed that the drug release from the composites took place in three stages. In the beginning drug adjacent to the polymer layer or on the surface diffuses into the release medium—a stage typically known as “the initial burst”. The magnitude depends entirely on the amount of drug present in this area. This stage took place from time zero to one day. Then slowly polymer degradation starts to take place leading to the formation of pores on the polymer layer, which paves the way for fluid transport for drug dissolution beneath the polymer layer and on the fabric. At this stage, drug release is by diffusion through these pores, which also control the mass transfer. This stage took place between 2 days and 10 days. After this stage, more pores would cumulatively grow and coalesce, allowing PBS to penetrate the matrix and hydrolyse it more. At this stage, there might be a secondary burst as the polymer layer opens up due to degradation. Then the drug will progressively be released until complete degradation of the polymer layers. The release study was conducted in only 2 weeks, a time that is not enough to see a complete degradation of the matrix.

The release rate for fabric coated with 0.01 g/mL polymer looks to be the highest compared with other fabric with thicker PLA layers. In our previous study [1], loading drug directly to the fabric resulted in the fast release rate and within 5 days more than 80% of the drug was released. For prolonged period release applications, combination of fabric with hydroxyapatite derived coralline skeletons seemed to control the release and improve the release time for wide clinical applications.

3.5 Bacterial efficacy for natural antimicrobial agent from the developed fabric composites

Honey and turmeric have been used as natural antimicrobial agents for different applications. Figures 7 and 8 represent a photograph of disc assay results and the inhibition area from the disc assay experiment respectively. Honey and turmeric were experimented with in different ratios and their effect against pathogens was compared to the clinical antibiotic. It was revealed that honey could inhibit microbial growth to a large extent and could be used for clinical treatment of wounds. On the other hand, when combining honey and turmeric the effect towards bacteria is not positive. This could be due to the different actions these materials have towards bacteria. The ability to inhibit bacterial growth for turmeric is almost half that of the honey.

4 Conclusions and recommendations

Coralline skeletons have the unique architectures that can be used for different clinical applications such as tissue engineering and drug delivery. These skeletons were successfully converted to calcium phosphate materials (HAp) through the mechano-chemical technique and used as a drug carrier. The hand-weaving process was used to develop cotton fabric. This method provides opportunities to specifically customize the fabric porosities for different clinical applications. The fabrics made from this process displayed good physical and mechanical properties suitable for drug release wound dressing materials. It was revealed that fabric embedded with coralline derived hydroxyapatite have mechanical strength 25–44% lower than the neat fabric but enough for the intended applications. On the other hand, HAp in the fabric improved drug release control, which improves drug bioavailability and efficacy. Biodegradable polymer coatings on the HAp loaded cotton fabrics suggested to control the drug release rate. The polymer coating thickness can be controlled to tailor different release kinetics. The developed fabrics have also displayed the ability to uptake and release honey and turmeric, enough to inhibit microbial growth. The results suggested that honey and turmeric could be loaded or coated to the developed fabric for wound dressing applications. Based on the findings it is recommended an in vivo study of the developed drug delivery composites. This will reveal a good picture of the drug delivery kinetics, important information for clinical studies.

References

Macha IJ, Muna MM, Magere JL (2018) In vitro study and characterization of cotton fabric PLA composite as a slow antibiotic delivery device for biomedical applications. J Drug Deliv Sci Technol 43:172–177. https://doi.org/10.1016/j.jddst.2017.10.005

Gurtner GC, Werner S, Barrandon Y, Longaker MT (2008) Wound repair and regeneration. Nature 453:314. https://doi.org/10.1038/nature07039

Scacchetti FAP, Pinto E, Soares GMB (2017) Functionalization and characterization of cotton with phase change materials and thyme oil encapsulated in beta-cyclodextrins. Prog Org Coat 107:64–74. https://doi.org/10.1016/j.porgcoat.2017.03.015

Shao D, Gao Y, Cao K, Wei Q (2017) Rapid surface functionalization of cotton fabrics by modified hydrothermal synthesis of ZnO. J Text Inst 108(8):1391–1397. https://doi.org/10.1080/00405000.2016.1254581

Massella D, Leone F, Peila R, Barresi AA, Ferri A (2018) Functionalization of cotton fabrics with polycaprolactone nanoparticles for transdermal release of melatonin. J Funct Biomater 9(1):1

Pinho E, Calhelha RC, Ferreira ICFR, Soares G (2019) Cotton-hydrogel composite for improved wound healing: antimicrobial activity and anti-inflammatory evaluation—Part 2. Polym Adv Technol 30(4):863–871. https://doi.org/10.1002/pat.4519

Wang Y, Zhou P, Xiao D, Zhu Y, Zhong Y, Zhang J, Sui X, Feng X, Xu H, Mao Z (2019) Chitosan-bound carboxymethylated cotton fabric and its application as wound dressing. Carbohyd Polym 221:202–208. https://doi.org/10.1016/j.carbpol.2019.05.082

Ajovalasit A, Sabatino MA, Todaro S, Alessi S, Giacomazza D, Picone P, Di Carlo M, Dispenza C (2018) Xyloglucan-based hydrogel films for wound dressing: structure-property relationships. Carbohyd Polym 179:262–272. https://doi.org/10.1016/j.carbpol.2017.09.092

Bozaci E, Akar E, Ozdogan E, Demir A, Altinisik A, Seki Y (2015) Application of carboxymethylcellulose hydrogel based silver nanocomposites on cotton fabrics for antibacterial property. Carbohyd Polym 134:128–135. https://doi.org/10.1016/j.carbpol.2015.07.036

Evranos B, Aycan D, Alemdar N (2019) Production of ciprofloxacin loaded chitosan/gelatin/bone ash wound dressing with improved mechanical properties. Carbohyd Polym 222:115007. https://doi.org/10.1016/j.carbpol.2019.115007

Liakos I, Rizzello L, Hajiali H, Brunetti V, Carzino R, Pompa PP, Athanassiou A, Mele E (2015) Fibrous wound dressings encapsulating essential oils as natural antimicrobial agents. J Mater Chem B 3(8):1583–1589. https://doi.org/10.1039/C4TB01974A

Rajput M, Bhandaru N, Barui A, Chaudhary A, Paul RR, Mukherjee R, Chatterjee J (2014) Nano-patterned honey incorporated silk fibroin membranes for improving cellular compatibility. RSC Adv 4(84):44674–44688. https://doi.org/10.1039/C4RA05799F

Jull AB, Cullum N, Dumville JC, Westby MJ, Deshpande S, Walker N (2015) Honey as a topical treatment for wounds. the Cochrane database of systematic reviews (3):Cd005083. https://doi.org/10.1002/14651858.cd005083.pub4

Pramanik N, Mitra T, Khamrai M, Bhattacharyya A, Mukhopadhyay P, Gnanamani A, Basu RK, Kundu PP (2015) Characterization and evaluation of curcumin loaded guar gum/polyhydroxyalkanoates blend films for wound healing applications. RSC Adv 5(78):63489–63501. https://doi.org/10.1039/C5RA10114J

Lund-Nielsen B, Adamsen L, Kolmos HJ, Rørth M, Tolver A, Gottrup F (2011) The effect of honey-coated bandages compared with silver-coated bandages on treatment of malignant wounds—a randomized study. Wound Repair Regen 19(6):664–670. https://doi.org/10.1111/j.1524-475X.2011.00735.x

Macha IJ, Cazalbou S, Ben-Nissan B, Harvey KL, Milthorpe B (2015) Marine structure derived calcium phosphate-polymer biocomposites for local antibiotic delivery. Mar Drugs 13(1):666–680. https://doi.org/10.3390/md13010666

Macha IJ, Cazalbou S, Shimmon R, Ben-Nissan B, Milthorpe B (2017) Development and dissolution studies of bisphosphonate (clodronate)-containing hydroxyapatite-polylactic acid biocomposites for slow drug delivery. J Tissue Eng Regen Med 11(6):1723–1731. https://doi.org/10.1002/term.2066

Ben-Nissan B, Macha I, Cazalbou S, Choi AH (2016) Calcium phosphate nanocoatings and nanocomposites, part 2: thin films for slow drug delivery and osteomyelitis. Nanomed (Lond) 11(5):531–544. https://doi.org/10.2217/nnm.15.220

Macha IJ, Ben-Nissan B, Müller WH (2017) Kinetics and the theoretical aspects of drug release from PLA/HAp thin films. Key Eng Mater 758:113–119. https://doi.org/10.4028/www.scientific.net/KEM.758.113

Cegla R-NR, Macha IJ, Ben-Nissan B, Grossin D, Heness G, Chung R-J (2014) Comparative study of conversion of coral with ammonium dihydrogen phosphate and orthophosphoric acid to produce calcium phosphates. J Aust Ceram Soc 50(2):154–161

Yaghoobi R, Kazerouni A, Kazerouni O (2013) Evidence for clinical use of honey in wound healing as an anti-bacterial, anti-inflammatory anti-oxidant and anti-viral agent: a review. Jundishapur J Nat Pharm Prod 8(3):100–104. https://doi.org/10.17795/jjnpp-9487

Muruke MH (2014) Assessment of quality of tanzanian honey based on physicochemical properties. Food Sci Qual Manag 33:61–72

Rey C, Marsan O, Combes C, Drouet C, Grossin D, Sarda S (2014) Characterization of calcium phosphates using vibrational spectroscopies. In: Ben-Nissan B (ed) Advances in calcium phosphate biomaterials. Springer, Berlin, pp 229-266. https://doi.org/10.1007/978-3-642-53980-0_8

Macha IJ, Boonyang U, Cazalbou S, Ben-Nissan B, Charvillat C, Oktar FN, Grossin D (2015) Comparative study of Coral Conversion, Part 2: microstructural evolution of calcium phosphate. J Aust Ceram Soc 51(2):149–159

Liu W-C, Wang H-Y, Lee T-H, Chung R-J (2019) Gamma-poly glutamate/gelatin composite hydrogels crosslinked by proanthocyanidins for wound healing. Mater Sci Eng, C 101:630–639. https://doi.org/10.1016/j.msec.2019.04.018

Liu WC, Lin Y-C, Xu M, Nabilla SC, Lin Y-L, Chen L-C, Chung R-J (2018) Study of collagen/γ-PGA polyelectrolyte multilayers coating on plasma treated 316 L stainless steel substrates. Surf Coat Technol 350:755–761. https://doi.org/10.1016/j.surfcoat.2018.04.073

Siepmann J, Siepmann F (2008) Mathematical modeling of drug delivery. Int J Pharm 364(2):328–343. https://doi.org/10.1016/j.ijpharm.2008.09.004

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Macha, I.J., Sufi, S. Novel slow drug release bioceramic composite materials for wound dressing applications: potential of natural materials. SN Appl. Sci. 2, 176 (2020). https://doi.org/10.1007/s42452-020-1977-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-020-1977-z