Abstract

Composite materials can be successfully applied to the manufacturing process in the consumer electronics field and can drastically reduce the weight of the several parts. For this reason, it is important to predict the shape change after carrying out compression molding of composite material and to determine the key parameters of the manufacturing process. In this paper, the compression molding process of a notebook computer cover using composite materials was analyzed by the finite element method. In addition, the signal-to-noise ratio has been calculated for the warpage deformations that occurred on the surface of the notebook computer cover. The design of experiment method was applied to determine the optimal parameters in the process. Levels of the optimal process factors were selected for minimum warpage deformation and to verify the proposed method; a physical notebook computer cover was manufactured using these optimal conditions. Experimental results, including those on warpage deformations, show that the proposed method can be useful in the manufacturing of lightweight notebook computer covers using a compression molding machine.

Similar content being viewed by others

1 Introduction

Recently, the demand for light and robust components has exploded with the development of commercial portable electronic devices. For this reason, methods for manufacturing electronic components using light and durable composite materials as replacements for existing metal parts are widely used. In particular, a portable notebook computer cover is known to be an effective component that gives weight reduction through the introduction of composite materials, as exemplified in many industrial fields [1,2,3].

To make mechanical parts using composite materials, many manufacturing methods including autoclaving, injection molding, resin transfer molding, and prepreg compression molding have been used. These have several advantages and disadvantages in terms of productivity and part strength, respectively. Usually, the notebook computer cover has a thin, flat, and curved shape and is required to have a flat surface for mechanical rigidity. In addition, it should be easy to assemble for mass production and have aesthetic characteristics. In order to satisfy these conditions, the prepreg compression molding method can be applied to fabricate the notebook computer cover. In this method, to manufacture a product, prepregs are stacked according to an arrangement, pressurized and cured through a mold (warm mold) heated by a hot plate, and finally cooled and demolded. Since this method uses a prepreg in which resin is probed on carbon fiber, it has the advantage of shortening the production time and securing the mechanical strength of the product compared with using an autoclave or injection molding method. In addition, it is known to be an advantageous method for mass production of mechanical parts having a relatively complicated shape since the mold can be molded into various shapes [4].

In order to apply the prepreg compression molding method to the actual product molding, it is necessary to investigate the effect of the control factors in the molding process including the various mold shapes and the process parameters such as mold temperature. Also, it is important to determine the process factors that can maximize the performance of the notebook computer cover. To this end, studies on the effects of flow modeling and related factors to describe the compression process using composite materials have been carried out by several researchers [5,6,7]. Also, many studies have been conducted to analyze the effects of several process factors [8,9,10,11]. The effects of the several process factors including filling time, mold temperature, gate dimensions, etc. in the plastic injection molding process were analyzed in the case of thin plate [8] and car switch button [9]. Also, the studies have been conducted to analyze the effects of the process conditions on the shrinkage of injection molded polypropylene [10] and the hyper-elastic materials characterization [11]. Among these, various optimization approaches including the multiresponse surface methodology and machine learning were employed to find the conditions necessary to obtain an optimal performance index [12,13,14,15]. Various optimization approaches including machine learning [12, 13], the response surface method [14, 15] and deep reinforcement learning framework [16] were employed to find the conditions necessary to obtain an optimal performance index. Also, the Taguchi’s method has been adopted for machining aluminum composite [17] and weld line of polypropylene [18] for optimization of process parameters. In addition, many studies have been conducted based on computation results from the finite element method, whereas few studies have considered the process variables necessary for actual mass production [16,17,18,19,20,21,22,23]. In addition, the warpage reduction with variable pressure profile has been studied by finite element analysis [19] and the experimental visualization of the flow during mold closure has been reported [20]. Meanwhile, the compression molding of sheet mold has been studied with fluid dynamic approach [21]. Also, the finite element model has been applied to the several molded part with various shapes [22, 23], whereas few studies have considered the process variables necessary for actual mass production.

In this study, when the prepreg compression molding method was applied to the manufacturing of a notebook computer cover, the design factors such as mold shape, mold pressure, mold temperature, and mold time were selected as the main factors. These are the process variables necessary for actual mass production using, for example, compression molding with composite materials. To find the optimal conditions, the design of experiment (DOE) method was applied. The levels of each design factor were selected considering as much as possible the experience of workers in a real factory. The signal-to-noise ratio (S/N ratio) of the warpage deformation of the notebook computer cover generated during the compression molding process conditions was selected as the objective function for DOE. Through the maximization of the S/N ratio of the warpage deformation, it is possible to make a notebook computer cover part that is as flat as possible and that can also be easily assembled with other mechanical parts. Through DOE, the optimum conditions for each factor were determined and the product at these conditions was manufactured in an actual compression molding machine. The S/N ratio for warpage deformation in the manufactured notebook cover was compared with the predicted result using the finite element method to confirm the applicability of the manufactured product to the actual electronic device.

In the following sections, compression molding machine for the notebook cover part is first introduced, followed by compression molding analysis and prediction of optimal process parameters using DOE. Also, through the comparison of S/N ratios between finite element method and actual compression molding process, the capability and limitation of the current models are evaluated. Discussion on the results and future works are then summarized.

2 Compression molding machine for the notebook cover part made from composite material

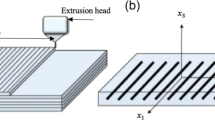

To accomplish the compression molding process using a composite material, a thin plate-like composite material or long-fiber prepreg sheet (LFPS) substrate is fixed to the compression molding apparatus and the mold is moved by a mechanical or hydraulic actuator as shown in Fig. 1. The mold assembly includes upper and lower molds that are located opposite each other. At the start of the process, the LFPS substrate is heated and maintained at the molding temperature set in advance for the hot plate. As shown in Fig. 1, the hydraulic cylinder can move the lower mold in the upward vertical direction by receiving hydraulic pressure from the reservoir and controlling the amount of flow through the solenoid valve. Figure 2 is a photograph of the actual compression molding machine and the user can set the pressure to the machine in order to move the lower die in an upward direction at a constant speed. The hot plate can heat the mold to 150 degrees.

3 Determination of the control factor in the manufacturing of the notebook computer cover using DOE

The shape of the notebook computer cover in this research is shown in Fig. 3. The 360 mm wide, 265 mm long, and 3 mm thick flat plate was made from Lytex 4197 (Engineered Structural Compound, ESC) manufactured by Quantum Composite, USA. Also, in order to fabricate the notebook computer cover, the upper and lower molds were manufactured as shown in Fig. 4. As a reference, the lower mold shape has a moat-like structure to smooth the flow of the substrate during compression molding. In terms of meshes, tetrahedron elements with 12 layers along the thickness direction and estimated edge length of 1.4 mm were used to mesh the initial charge and mold space. The compression force was set to 66 kN and compression speed to 2 mm/s during the process, with a mold time of 510 s.

3.1 Compression molding analysis

Flow analysis software was used in this study to analyze the compression mold process of the 3D Timon Compress mold module from Toray, Japan [24]. Flow, packing, fiber, and warping modules are included in this analysis module and the several parameters including the mold temperature, mold pressure, and mold time, among others, can be inputted to simulate the flow pattern, mechanical properties of the molded part, and the fiber densities in the analysis region [25, 26]. Also, the pressure–volume–temperature (PVT) characteristics and viscous properties of the charged prepregs can be used to calculate a physical property database [27, 28]. As a result of mold analysis, filling time, fiber behavior, and warpage deformation, etc., are calculated. Filling time is a process variable representing the time that the front of the flow reaches each element. Figure 5 shows the distribution of the filling time for each element of the notebook computer cover at 6.98 s after the start of the compression molding process. Subsequently, the substrate undergoes warpage deformation after hardening and releasing. As shown in the right side of Fig. 5b, the contour plot of the warpage deformation can be predicted. The warpage deformation is high at the left and right edges of the notebook computer cover and decreases toward the center, and thus appears to be saddle shaped. Also, Fig. 5c shows the temperature distribution of the charge and mold space at the time of 1.0 s after the start of the compression molding. Initially, the temperature of the hot plate and mold were maintained at 150 degrees and the temperature of the charge increased as the process continued because the heat was transferred from the hot plate. As a reference, Fig. 5d depicts the velocity pattern across the charge at the time of 1.0 s and it can be shown that the velocity at the center in the thickness direction is maximum and nearly zero at the wall side.

3.2 Prediction of optimal process parameters in the compression molding using DOE

Using the finite element analysis results outlined in Sect. 3.1, DOE was applied to predict the optimal process parameters in the compression molding process [18, 29]. To this purpose, we set the four control factors of aspect ratio of the mold, compression force, mold temperature, and mold time. First, the aspect ratio is the proportion of the horizontal dimension H and vertical dimension V in the mold for the notebook computer cover as shown in Fig. 6a. After the substrate is inserted between the upper and lower molds, the molding process is started by providing a compression force from the hydraulic cylinder that is set by the operators. At this time, the lower mold has already warmed up to the mold temperature of the hot plate. Also, after the hydraulic cylinder has been moved down, the substrate is deformed according to the shape of the upper and lower molds. The mold time is the elapsed time from lowering of the hydraulic cylinder to taking out the base material from the mold.

For the effective mass production of notebook computer cover parts, the upper surface to which an assembly bolt is fastened should be as flat as possible for easier assembly. Therefore, we selected the S/N ratio of the warpage deformations at several points on the upper surface of the notebook cover part as an objective function in DOE. Based on the operator’s experience, L9 orthogonal arrays can be configured for four control factors and three levels as shown in Table 1. By using the mold analysis results at 25 points as shown in Fig. 6b, the S/N ratio can be calculated as shown in Eqs. (1) and (2). A larger S/N ratio means a smaller deviation of the warpage deformations at 25 points from the mean value, so that the notebook computer cover part can then be more easily bolted to other parts.

Here, n is the number of measuring points, V is the variance of warpage deformations, y is the warpage deformation at each measuring point, and \(\bar{y}\) is the average of the warpage deformations. In this study, the warpage deformation calculated from the Warpage module of Timon 3D, was applied in each case to determine the optimal level for each factor.

Warpage deformation results of notebook computer cover part using an L9 orthogonal array is shown in Table 2. The main effect plots for each factor are shown in Fig. 7. For larger S/N ratios, we need to decrease the aspect ratio, compression force, and molding time in the compression molding of the notebook computer cover part. Also, a greater mold temperature can cause a larger S/N ratio. As a result of applying DOE, the optimal conditions for the maximum S/N ratio can be estimated as aspect ratio 1.04, compression force 66 kN, mold temperature 144 degrees, and mold time 300 s.

3.3 Comparison of S/N ratios between finite element method and actual compression molding process

A notebook computer cover part (case 6 in Table 1) was manufactured in a compression molding machine. A picture of the manufactured part for warpage deformation is shown in Fig. 8a, b. To compare the results of the manufactured part with the one obtained by the finite element method, a height gauge was used to measure the height value δh in the vertical direction which is the distance between the contact point of the gauge to the notebook computer cover and the lowest point of the notebook computer cover based on a reference granite bed. As shown in Fig. 6b, height values were taken at 25 points on the surface of the molded notebook cover part. In addition, to account for the thickness of the part, the thickness value δt was measured for the same 25 points using the thickness gauge, and the warpage deformation δ was calculated by subtracting the thickness value from the vertical height values measured using the height gauge. The reason why thickness values are subtracted by the vertical height values is that the thickness of the notebook cover part can vary at the measuring points. Also, the S/N ratios can represent the fluctuation characteristics of the surface of the molded mechanical part which has been deformed during the molding process. As shown in Table 3, it can be seen that S/N ratios for the analysis results and the measurement results are in close agreement with each other, within about 10%.

4 Conclusions

In this study, to minimize the variation of warpage deformation in the compression molding of a notebook computer cover, flow analysis has been performed and DOE was applied. First, as a result of flow analysis, it was found that the substrate properly reached the mold surface during the compression process and the distribution of warpage deformation could be predicted. Second, DOE was applied to investigate the effect of mold shape and representative process variables on warpage deformation. As a result of applying DOE, the control factors that affect the variation of warpage deformation were presented and the level of the factors for maximum S/N ratio of the warpage deformation have been determined. In addition, to confirm the validity of the proposed method, warpage deformation was measured through actual compression molding experiments and the measured results were within 10% of the analysis results, confirming the applicability of this proposed method for the optimization of the compression molding of a notebook computer cover part. Future studies will focus on providing the optimization method which can consider the fiber orientation characteristics of the molded part.

References

Park H, Cha B, Rhee B (2010) Prediction of flash generation in two-color injection molding using the rapid heat cycle molding technology. Trans Mater Process 19(3):145–151. https://doi.org/10.5228/KSPP.2010.19.3.145

Lee S, Lee J, Jo W, Kim Y (2015) Aluminum plate forging of laptop case for high strength, lightweight. In: Proceedings of the Korean society for precision engineers conference 11

Park M, Joun M, Kim D, Shin H, Lee C (2017) Process design of plate forging component using design of experiment and finite element analysis. In: Proceedings of the Korean society for technology of plasticity conference, pp 139–140

Lee JM, Kim BM, Ko DC (2016) CFRP compression forming technology. Trans Mater Process 25(3):203–208

Jo S, Lim Y, Kim E (1996) Simulation of compression molding with anisotropy of continuous fiber-reinforced polymeric composites. Compos Res 9(1):1–9

Chae K, Jo S, Kim E (1999) 3-Dimensional deformation analysis for compression molding of polymeric composites with random/unidirectional fiber-reinforced laminates. Compos Res 12(5):23–30

Ryoo H, Lee D, Kim E (1993) An effect of fiber length on the correlation between separation and orientation of flow molded fiber-reinforced polymeric composites. Compos Res 6(1):19–28

Tang S, Tan Y, Sapuan S, Sulaiman S, Ismail N, Samin R (2007) The use of Taguchi method in the design of plastic injection mould for reducing warpage. J Mater Process Technol 182(1–3):418–426. https://doi.org/10.1016/j.jmatprotec.2006.08.025

Kim C, Park J (2016) Optimization of an injection molding process for polycarbonate car switch buttons using the Taguchi method. Compos Res 29(1):7–15. https://doi.org/10.7234/composres.2016.29.1.007

Altan M (2010) Reducing shrinkage in injection moldings via the Taguchi, ANOVA and neural network methods. Mater Des 31(1):599–604. https://doi.org/10.1016/j.matdes.2009.06.049

Saúl Í-M, Rubén L-L, María E-G, Ángeles M-C (2019) Finite element model updating combined with multi-response optimization for hyper-elastic materials characterization. Materials (Basel) 12(7):1019. https://doi.org/10.3390/ma12071019

Bobadilla MC, Martinez RF, Lorza RL, Gomez FS, Gonzalez EPV (2018) Optimizing biodiesel production from waste cooking oil using genetic algorithm-based support vector machines. Energies 11(11):2995. https://doi.org/10.3390/en11112995

Zhang S, Dubay R, Charest M (2015) A principal component analysis model-based predictive controller for controlling part warpage in plastic injection molding. Expert Syst Appl 42(6):2919–2927. https://doi.org/10.1016/j.eswa.2014.11.030

Bobadilla MC, Lorza RL, Garcia RE, Gomez FS, Gonzalez EPV (2019) Coagulation determination of key operating parameters by multi-response surface methodology using desirability functions. Water 11(2):398. https://doi.org/10.3390/w11020398

Kim KT, Lee GA, Choi S, Lee HW, Lee Y-S (2008) Prediction of shape accuracy in elastomer-forming of a cylindrical tube by a response surface method. Trans Mater Process. https://doi.org/10.5228/kspp.2008.17.3.218

Lee XY, Balu A, Stoecklein D, Ganapathysubramanian B, Sarkar S (2019) A case study of deep reinforcement learning for engineering design: application to microfluidic devices for flow sculpting. J Mech Des 141(11):111401. https://doi.org/10.1115/1.4044397

Tamizharasan T, Senthilkumar N, Selvakumar V, Dinesh S (2019) Taguchi’s methodology of optimizing turning parameters over chip thickness ratio in machining P/M AMMC. SN Appl Sci 1:160. https://doi.org/10.1007/s42452-019-0170-8

Ozcelik B (2011) Optimization of injection parameters for mechanical properties of specimens with weld line of polypropylene using Taguchi method. Heat Mass Transf 38(8):1067–1072. https://doi.org/10.1016/j.icheatmasstransfer.2011.04.025

Kitayama S, Onuki R, Yamazaki K (2014) Warpage reduction with variable pressure profile in plastic injection molding via sequential approximate optimization. Int J Adv Manuf Technol 72:827–838. https://doi.org/10.1007/s00170-014-5697-7

Odenberger PT, Andersson HM, Lundstromproen TS (2004) Experimental flow-front visualization in compression molding of SMC. Compos Part A 35:1125–1134. https://doi.org/10.1016/j.compositesa.2004.03.019

Kluge NEJ, Lundstrom TS, Westerberg LG, Olofsson K (2015) Compression molding of sheet molding compound: modelling with computational fluid dynamics and validation. J Reinf Plast Compos 34(6):479–492. https://doi.org/10.1177/0731684415573981

Han MG, Bae JH, Lee SW, Chang SH (2017) Optimal design of long-fiber composite cover plate with ribs. Compos Res 30(1):65–70. https://doi.org/10.7234/composres.2017.30.1.065

Song Y, Gandhi U, Sekito T, Vaidya UK, Hsu J, Yang A, Osswald T (2018) A novel CAE method for compression molding simulation of carbon fiber-reinforced thermoplastic composite sheet materials. J Compos Sci 2(2):33. https://doi.org/10.3390/jcs2020033

Toray Engineering Co., Ltd. (2015) 3D Timon 10 tutorial. 3rd release, Japan

Chang C-Y (2006) Simulation of mold filling in simultaneous resin injection/compression molding. J Reinf Plast Compos 25(12):1255–1268. https://doi.org/10.1177/0731684406060253

Chen Z, Huang T, Shao Y, Yang L, Xu H, Avery K, Zeng D, Chen W, Su X (2018) Multiscale finite element modeling of sheet molding compound (SMC) composite structure based on stochastic mesostructure reconstruction. Compos Struct 188(15):25–38. https://doi.org/10.1016/j.compstruct.2017.12.039

Capela C, Oliveira SE, Pestana J, Ferreira JAM (2017) Effect of fiber length on the mechanical properties of high dosage carbon reinforced. Procedia Struct Integr 5:539–546. https://doi.org/10.1016/j.prostr.2017.07.159

Kim HS, Chang SH (2019) Simulation of compression moulding process for long-fibre reinforced thermoset composites considering fibre bending. Compos Struct 230:111514. https://doi.org/10.1016/j.compstruct.2019.111514

Park SH (2003) Modern design of experiment (Chapter 18). Minyoung Publishing Co., Paju. ISBN 978-89-8134-120-6

Acknowledgements

This research was supported by the Ministry of Trade, Industry, and Energy, and the Defense Acquisition Program Administration (15-CM-MA-15).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kim, HS., Lee, WG., Lee, CH. et al. Optimization for the prepreg compression molding of notebook computer cover using design of experiment and finite element method. SN Appl. Sci. 2, 1619 (2020). https://doi.org/10.1007/s42452-020-03416-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-020-03416-4