Abstract

The sustainable economic advancement of a nation stands on an adequate supply of electrical energy. Reduction in cost for industrial processing units has been pulled with the wide utilization of rice husk (RH) and solar energy as value-added renewable energy sources for the era of power generation. The principal reason is to assist the study area towards development and to build up an integrated hybrid renewable power plant in rural regions in India. In this study, a new solar town concept and integrated biomass can be served as a hybrid global model for a smart eco-village in tropical countries like India. The demand, properties and cost of RH generation from rice mills resemble substitution of coal in power generation. Solar energy and agricultural residues are seasonally accessible sources and loosely dispersed over the substantial topographical area. So, for such an assessment, satellite image is a handy input and the preciseness of estimation increases with a high-resolution image. The methodology has been implemented for optimal sizing of an integrated renewable energy system-based power generation plants in India with less investment and minimum power cost. The outcome of the study reveals that the efficient use of renewable energy sources and proposal for placing a power generation plant require cautious identification of various techno-economic parameters. By considering the power crisis in India, the findings of these works are expected to assist the policymakers in the decision-making process. Particularly, this paper generates data on village-level RH availability from rice mills and subsequently potential electric power capacity for a particular region.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In this modern era, the entire world is focusing on economic and viable energy resources for the generation of electricity. The demand for electricity is increasing all over the world, and mostly power generation is through conventional energy sources. But in future, one day all these sources get deplete. Then, further no one can utilize these sources, so there is a necessity for alternate energy sources and a greener way to generate electricity [1]. Presently, renewable energy sources have such potential to replace them and every nation is looking forward for better approach to utilize these sources for generating electricity.

A country like India has huge potential and demand for solar, biomass and wind for power generation. Particularly, the utilization of electricity is huge and renewable energy power generation constitutes only 29.9% of total installed capacity [2, 3]. It is an agro-based country, and the main crop of production is paddy. So, the amount of rice husk generation from the rice mills is huge, by using which good amount of electricity can be generated and distributed to rural areas at less expensive rate [4]. Solar energy is free source of energy, which is generated from the sun’s core; it can be utilized and converted to electricity by using photovoltaic cells (panels). In the current scenario, photovoltaic (PV) energy generation can produce and fulfil enough power to compete with large-scale markets and a number of advanced solar panel manufacturing industries prompted a dramatic drop in costs [5].

It is truly concerned that these energy sources are seasonally available and for large-scale utilization limited amount of energy can be generated with individual sources. So, an integrated hybrid technology needed to be implemented for continuous production of electricity for longer periods. For this approach initially, the plan must be developed for the implementation of the integrated system in large scale [6]. Through image processing technology, it is easy to assess the better location to place an integrated power plant by considering land surface temperature map, locations of rice mills, road network system, transportation, environmental aspects, land availability and cost.

2 Study area

Among all the districts in Andhra Pradesh, West Godavari district is one of the huge paddy-cultivating districts and has the highest potential to generate electricity from solar energy. In this study, rice husk production is required for determining the potential of electricity and that information is obtained from the individual rice mills. To place the power generation plant, a preliminary study is required for solar radiation estimation and to find the optimal location. The effective optimal route for the road network can be identified for rice mills by considering the optimum road network method (Fig. 1).

2.1 Selection of biomass resource and its importance

Biomass is one of the energy utility sources derived from plants. The energy obtained from these sources is reliable, and it is free of variances, unlike other energy sources. This form of energy is commonly used around the world, but for warmth and cooking purposes, most people use it. Unfortunately, during this process, the huge amount of carbon dioxide is discharging to the atmosphere. Instead of utilizing these biomass sources for polluting the environment, it can be utilized in a proper manner like methane generation, alcohol production and used as a fuel source for the generation of electricity [4]. When renewable resources are efficiently reused, the production of energy would be cheaper than coal and fossil fuels.

2.1.1 Rice husk from paddy

Rice husk is an agricultural residue, and it is generated from rice mills as by-product. The annual production of rice husk in India is around 120 million tons (NIIR project 2008). Because of the low sugar content and cellulose, it is not recommended for cattle as feed. In the larger part of rice-producing countries, a great part of husk is blazed or dumped as a waste [7]. For every 1 ton of paddy milled in the rice mill, 78% of weight is rice (broken rice, bran) and the remaining 22% of weight is a husk. With that amount of rice husk, nearly 410 kWh electricity can be generated [4]. Mostly, the rice husk contains 75% of organic matter and the remaining 25% is converted into ash with that technique. In that rice husk ash (RHA), mostly 85-90% is composed of amorphous silica and the remaining amount is moisture content [7]. Silica is the major substance in RHA, and the extraction of silica from the ash is economical. Through this ash removal, it also becomes simple and would be an immense environmental advantage.

Using rice husk resource as a fuel for producing electricity would minimize the import of fossil fuels and raise local income. The comparison of properties between rice husk and coal is shown in Table 1.

The present market value of rice husk per kg is Rs 1.90 (field study).

For rural empowerment design, installation and mini power plant operations using rice husk gasification technology were developed by Panday and Binoy [8]. The process involves primarily burning the rice husk with a controlled oxygen supply to produce the hot gas that will be the source of an internal combustion engine and generate electricity.

2.2 Analysis of solar energy

The amount of solar radiation striking earth surface over a 3-day period is equivalent to the energy stored in fossil fuel energy sources. Photovoltaic solar power is one of the standout renewable energy sources all over the world. As it is a nonpolluting source, it requires little maintenance and no moving parts to replace and mostly it has a life span of nearly 30 years with low running cost. During this modern era, solar energy power generation has been shown to compete in cost with conventional sources [9]. Actually, the retail cost of conventional power is rising, while the cost of solar power is dropping [10]. Also, PV energy source is advantageous for the regions where grid-connected power is expensive or inconvenient. Mainly remote areas can easily produce their own supply of electricity with PV energy sources but the main problem is land acquisition. Continuously, PV market is growing as renewable energy source and manufacturers standardize installations, designs and efficient practices to further reduce price related to PV energy production [5]. With all these efforts, solar power production and expansion contributes only a little percentage of total global energy supply. The cost of solar-generated electricity is typically contrasted with electricity produced by conventional sources with a levelized cost of energy estimation. Investors and financial specialists need to know their expected profits on investment, regulators, controllers and policymakers [10]. The arrangement to implement PV farms in a certain location is in close proximity to the existing grid, and load poles reduce significantly transmission losses [11].

2.3 Integrated system

Nowadays, integrated hybrid power generation system becomes more popular, which implies it mainly focuses on combining renewable energy technologies together for better electricity transmission to the grid. It incorporates an advanced system of planning, design and operation of electric grid [12, 13]. There is a considerable measure of significance for this technology, and the principal benefits are:

-

1.

It reduces the peak load of customer and even reduces the cost of electricity.

-

2.

It significantly reduces the carbon emissions and other air pollutants through the wide utilization of integrated renewable energy sources.

-

3.

The system gives the enhanced security, reliability and resiliency for the electric grid.

-

4.

It gives support to the diminishment in oil and coal utilization.

Thus, there is a necessity to execute these innovative technologies in a better way to strengthen energy-efficient systems and renewable energy market. Energy policies will reduce the easy accessibility of renewable energies for all business sectors, for energy-efficient systems and cost-effectiveness of integrated energy-efficient systems [9]. In the view of the proposal, the RH and solar town concept brings the vicinity of eco-community to provide energy for localized energy system and the idea can provide environmental and technical benefits [6]. For an integrated hybrid system, the chosen renewable energy sources are biomass and solar which have huge potential in the study area.

2.4 Geographic information system model

The geographic data framework is an information handling strategy. It primarily integrates to improve the classifications and overall decision making. This can be possible by a spatially referenced computer database and proper utilization of software. It interfaces activities based on spatial vicinity. Image processing technique mainly incorporates points, lines and polygons with discrete objects. For these systems, data are the most essential and key parameters and the most expensive components of the geographic information system (GIS). The information that can be put in GIS is called data capture.

Spatial data are also known as geospatial data or spatial information. The process includes digitizing the locations, paths, geographic features, classification and boundaries in a suitable manner. Spatial analysis is one of the techniques connected to structures and involves analysis of geographic information or data. The challenge in spatial analysis is mainly because of the media of representation and power of maps. The GIS achieved a high level of maturity and emerged as a powerful tool to build biomass and solar strategies. GIS can be utilized for location suitability optimal site selection for power plants [11]. Presently in this paper, the integrated hybrid renewable energy system can be analysed through a geospatial model to locate the most appropriate location for placing a power plant. Through mathematical modelling, the potential of electricity can be calculated for the proposed system.

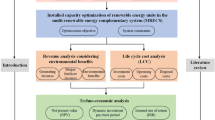

3 Methodology for siting integrated power plant

The whole concept and ideology for implementing the integrated hybrid renewable energy system are explained in Fig. 2.

3.1 Field analysis of rice husk generation data from rice mills

To perform the potential analysis in rice husk, data (rice husk availability) from every individual rice mill, i.e. amount of paddy milling every year in kg, are necessary.

Field study data:

-

1 ton of paddy rice produces 220 kg of rice husk

-

For milling 1 Quinta of rice, 3 kWh of electricity is required

-

Cost of I kWh of electricity is Rs 5.35

-

220 kg of rice husk generates 410 kWh

Through the field study, some valuable data are obtained and helpful to calculate the potential of electricity generation through RH. They are shown in Table 2.

3.2 Spatial analysis for locating rice mills

Locations of the rice mills are taken by using latitude and longitudes in image processing techniques. The rice mills and locations are plotted through image processing technique and shown in Figs. 3 and 4.

3.3 Designed formulae to calculate rice husk potential analysis

Rice husk is one of the feasible resources to generate electricity more than the requirement in the rice mills, and it has almost equal potential with the coal for generating electricity.

Derived formulae for calculating the potential of electricity that can be generated from rice husk and cost analysis [14,15,16]

where PRH is the potential of electricity in rice husk (kWh), ARH is the amount of RH (kg) and Aeh is the amount of electricity that can be generated from 1 kg of RH (kWh) 1.86 kWh.

where CRH is the obtained cost from RH utilization for electricity generation (Rs), PRH is the potential of electricity in RH (kWh) and Ceh is the cost of electricity for 1 kWh 5.35 (Rs)

By using these formulae, it estimates the feasible amount of electricity that can be generated through rice husk.

3.3.1 Rice mill utilization analysis

Derived formulae for the consumption of electricity to mill the rice in the rice mill and cost analysis.

where Srm is the consumption of electricity (kWh), Arm is the amount of paddy (kg), Aem is the electricity utilization per kg (kWh) 0.03 kWh.

where Crm is the total cost of electricity consumption (Rs), Srm is the consumption of electricity (kWh), Cem is the cost of electricity for 1 kWh 5.35 (Rs).

The utilization of rice husk as a potential source for generating electricity gives favourable results, and economic analysis is performed by using the designed formulae. The results are shown in Table 3.

By considering biomass power generation efficiency of 25% [12] by using 1 kg of rice husk as a fuel source for electricity generation, nearly 15.5 kg of paddy rice can be milled.

4 Feasibility analysis of solar energy

For calculating solar radiation for the described study area as per objective 1, precise analysis is required. This analysis is carried out through the image processing technique. To analyse the temperature for a particular location, corresponding satellite data with frequent repetition are used. The average volume of solar radiation near the rice mill positions is determined by using these satellite data. This is done through classifying and analysing the data sets.

The Landsat-8 satellite data for 3 years are used to calculate the solar radiation capacity for a particular region. To measure solar radiation and land surface temperature, bands 10 and 11 are used for analysis. During the classification, the image will be classified to digital number values. The DN values are converted to land surface temperature (°C). Landsat-8 measures different ranges of frequencies along with the electromagnetic spectrum. The wavelengths of bands 10 and 11 are 10.6–11.2 and 11.5–12.5, respectively. To measure solar radiation and land surface temperature, bands 10 and 11 are used for analysis. Bands 10 and 11 are in the thermal infrared (TIR)—calculates the land surface temperature. Like weather stations, instead of measuring the temperature of air, this methodology gives even much hotter classification for a particular region. In bands 10 and 11, results are getting much difference in temperature. Mainly band 11 is getting less temperature when compared with band 10 because band 11 is being closer to powerful micron band of CO2 and it is influenced by atmosphere than band 10 [17]. Truly to understand the temperature variation with satellite data from weather stations, air temperature recordings are collected to know the real-time variation in temperature. The land surface temperature is classified for the study area, and it is shown in Fig. 5.

For the proposed study area, 3-year data (2014, 2015 and 2016) for every month are considered and through image processing technique land surface temperature is classified. Throughout the whole analysis for every month with classified land surface temperature, the maximum temperature is obtained on 23 May 2015. So for those particular day data under the study area, analysis is performed and the results are compared with other years’ data. With the classification acquired, five places get more solar radiation and their latitudes and longitudes are:

-

16° 42′ 43.23″ N 81° 45′ 00.07″ E

-

16° 44′ 52.93″ N 81°42′ 43.51″ E

-

16° 46′ 40.80″ N 81°39′ 32.40″ E

-

16° 44′ 27.60″ N 81°39′ 18.00″ E

-

16° 45′ 18.00″ N 81°38′ 32.40″ E

And they are shown in Fig. 6.

Including road network, infrastructure, land mobility, land quality, viability, distance and environmental considerations, one of five areas will recommend a particular site for the placing of solar power plants. With the detailed classification and analysis, five locations were proposed and plotted. They are shown in Fig. 6.

4.1 Measurement of solar radiation

A thorough preliminary analysis is required to know the solar radiation for a specific area. The quality of sunlight mainly relates to spectral nature and gives an introduction in all aspects of solar resource assessment. This study reveals the proper implementation and gives feasible siting location for the solar energy power plant. So, for that, certain parameters are considered which are shown in Table 4.

4.2 Methodology for solar power generation

To effectively deploy a solar power system in a particular area, a thorough study of demand requirement, peak rate, overall energy usage, energy payback and annual energy usage is required. The environmental issues and overall pollution need to be addressed primarily for this type of specific research. So, by considering all these aspects, a detailed methodology for solar power generation is explained in Fig. 7.

4.2.1 Design and assessment of solar energy

Through image processing technique, land surface temperature is classified. The maximum amount of solar radiation is estimated, and a particular feasible location is selected for placing solar plant nearer to the rice mills. So, for proposing or implementing a solar power plant, a certain analysis is needed to be performed and detailed methodology is shown and designed calculations for a photovoltaic system are shown as follows:

-

1.

Panel generation factor is a key factor in designing a solar PV plant. While calculating the size of solar photovoltaic cells, panel generation factor is used and it is a fluctuating factor relying on the climate and location [18]. Average daily solar radiation in the proposed power plant location is 5.6 kWh/m2/day (pvwatts.nrel.gov)

$$\begin{aligned} {\text{Panel}}\;{\text{generation}}\;{\text{factor}}\;\left( {P_{\text{g}} } \right) & = {\text{daily}}\;{\text{solar}}\;{\text{radiation/standard}}\;{\text{test}}\;{\text{conditions}}\;{\text{irradiance}}\;{\text{for}}\;{\text{PV}}\;{\text{panels}} \\ & = \left( {5.6*1000} \right) /100 \\ & = 5.6 \\ \end{aligned}$$(5) -

2.

The total number of modules required for the proposed power plant relies on the total area required for the plant, dimensions of the module and peak rating of the modules:

$$\begin{aligned} {\text{No}}.\;{\text{of}}\;{\text{modules}}\;{\text{required}}\;\left( {N_{\text{PV}} } \right) & = \,{\text{total}}\;{\text{area}}\;{\text{of}}\;{\text{modules/length}}\;*\;{\text{width}}\;{\text{of}}\;{\text{modules}} \\ = & 20 ,234.5 \div \left( {1.65 \times 1} \right) \\ = & 12 ,263 \\ \end{aligned}$$(6) -

3.

To identify system size, total watt peak rating for PV modules is calculated. It depends on a number of modules required for solar plant and PV module peak rated output (designed):

$$\begin{aligned} {\text{Total}}\;{\text{watt}}\;{\text{peak}}\;{\text{rating}}\;{\text{for}}\;{\text{PV}}\;{\text{modules}}\;\left( {W_{\text{p}} } \right) & = \,{\text{no}}.\;{\text{of}}\;{\text{modules}}\;{\text{required}}*{\text{PV}}\;{\text{module}}\;{\text{peak}}\;{\text{rated}}\;{\text{output}} \\ & = 12 ,263 \times 230 \\ & = 2820.5\;{\text{kW}} \\ \end{aligned}$$(7) -

4.

Watt peak rating for PV modules for the system will be the major factor for the energy required for the PV modules and panel generation factor:

$$\begin{aligned} {\text{Energy}}\;{\text{required}}\;{\text{from}}\;{\text{PV}}\;{\text{modules}}\;\left( E \right) & = \,{\text{watt}}\;{\text{peak}}\;{\text{rating}}\;{\text{for}}\;{\text{PV}}\;{\text{modules}}*{\text{panel}}\;{\text{generation}}\;{\text{factor}} \\ & = 2820.5 \times 5.6 \\ & = 15 ,738.4\; {\text{kWh/day}} \\ \end{aligned}$$(8) -

5.

Total energy required to be supplied for solar PV system is considered as energy demand and necessary to consider system losses compensation factor as 30%:

$$\begin{aligned} {\text{Energy demand }}\left( {E_{\text{d}} } \right) & = \,{\text{energy required from PV modules / system losses compensation factor}} \\ & = 13 ,256.3 \times 1.3 \\ & = 12 ,106.5 \;{\text{kWh/day}} \\ \end{aligned}$$(9) -

6.

Any assessment of renewable energy system includes the total amount of energy consumed by all the processes associated with the system components for fabrication, building, manufacturing, materials, transportation, management, installations and product delivery for each m2 area of the module for the proposed system [19]:

$$\begin{aligned} {\text{Total}}\;{\text{energy}}\;{\text{consumed}}\;{\text{by}}\;{\text{materials}} & = \, 1 5 1 6. 6\;{\text{kWh/m}}^{ 2} \\ {\text{Total}}\;{\text{embodied}}\;{\text{energy}}\;\left( {E_{\text{t}} } \right) & = \,{\text{total}}\;{\text{area}}\;{\text{of}}\;{\text{modules }}*{\text{ total}}\;{\text{energy}}\;{\text{consumed}}\;{\text{in}}\;{\text{materials}} \\ & = 20 ,234.5 \times 1516.6 \\ & = 30 ,687.4\;{\text{MWh}} \\ \end{aligned}$$(10) -

7.

Annual electricity generation is the product of energy demand of the system and an average number of clear sunny days (solar.missionenergy.org):

$$\begin{aligned} {\text{Annual}}\;{\text{electricity}}\;{\text{generated}}\;\left( {E_{\text{g}} } \right) & = \,{\text{energy}}\;{\text{demand}}*{\text{no}}.\;{\text{of}}\;{\text{clear}}\;{\text{sunny}}\;{\text{days}} \\ & = 10 ,197.2 \times 300 \\ & = 3631.9\;{\text{MWh/year}} \\ \end{aligned}$$(11) -

8.

Energy payback time is defined as the ratio of the total embodied energy of modules to annual electricity generation from the plant:

$$\begin{aligned} {\text{Energy}}\;{\text{payback}}\;{\text{time}}\;({\text{EPBT}}) & = \,{\text{total}}\;{\text{embodied}}\;{\text{energy}}\;{\text{of}}\;{\text{modules/annual}}\;{\text{electricity}}\;{\text{generated}}\;{\text{from}}\;{\text{plant}} \\ & = 30 ,687.44 \div 3631.9 \\ & = 8.4\;{\text{years}} \\ \end{aligned}$$(12) -

9.

Electricity production factor is defined for any electricity-delivering installation, i.e. using renewable energy source like solar and biomass. It is the ratio of annual electricity generated from the plant to total embodied energy

$$\begin{aligned} {\text{Electricity}}\;{\text{production}}\;{\text{factor}}\;\left( {\text{EPF}} \right) & = \,{\text{annual}}\;{\text{electricity}}\;{\text{generated}}\;{\text{from}}\;{\text{plant/total}}\;{\text{embodied}}\;{\text{energy}} \\ & = 3631.9 \div 30,687.44 \\ & = 0.1 \\ \end{aligned}$$(13) -

10.

The performance and execution of the PV power plant are often represented as a capacity utilization factor. It is the ratio of annual energy generated for each kW peak capacity to the maximum possible output for a year under ideal conditions:

$$\begin{aligned} {\text{Capacity}}\;{\text{utilization}}\;{\text{factor}} & \, = \,{\text{annual}}\;{\text{energy}}\;{\text{generated}}\;{\text{for}}\;{\text{each}}\;{\text{kW}}\;{\text{peak}}\;{\text{capacity/no}}.\;{\text{of}}\;{\text{ hours}}\;{\text{in}}\;{\text{a}}\;{\text{year}} \\ = & \left( {3631.9 \times 1000 } \right) \div (2820.49 \times 8760) \\ = & 0.15 \\ \end{aligned}$$(14)

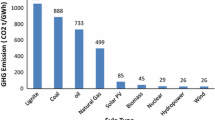

4.2.2 Reduction in estimating greenhouse gas emissions

-

1.

CO2 outflow from the embodied energy of the PV plant incorporates the outflow emissions in manufacturing, materials, transportation, product delivery, etc. If the generation, transmission and distribution losses for Indian conditions are considered, then the average CO2 per kWh can be taken as 1.58 kg [18]:

-

2.

The CO2 mitigation is the measure of CO2 emissions reduction by producing the energy from PV plant; otherwise, it would be released by another conventional power plant:

-

3.

Net CO2 mitigation is defined as the difference between CO2 mitigation over its life span, i.e. 30 years, and CO2 emissions:

-

4.

Carbon credits are granted and awarded against the reduction in CO2 and greenhouse gas emissions. These can be exchanged and traded in the universal market at their current market price:

-

5.

The earnings from carbon credits yearwise are defined as the ratio of carbon credits to the life span of the system:

The overall analysis in the assessment of solar power generation with the measurement of solar energy and designed calculations for the photovoltaic system are determined. The overall results are explained in Tables 5 and 6.

The detailed approach for installing solar power plant provides the subsequent solution and study of solar power production. An overall calculation for photovoltaic system design gives the overview assessment to build the system without any disruptions in future. Ultimately, this technology reduces conventional sources usage and balances the environment.

4.3 Assessment of Potential electricity through an integrated hybrid renewable system

Utilization of electricity in rice mills for paddy milling is 12, 370.5 MWh/year (rice mills, 2015–2016 database). Generation of rice husk from the rice mills during (2015–2016), the total amount of electricity that can be generated by the utilization of rice husk is 42, 182 MWh/year. By considering five acres of land in the proposed location, the total amount of electricity that can be generated by the utilization of solar energy is 3, 631.9 MWh/year. So, the overall potential of electricity that can be generated by the utilization of an integrated hybrid renewable energy system (rice husk and solar) is 45, 813.9 MWh/year.

4.3.1 Generation of electricity with an integrated system

Many integrated hybrid systems or models are developed based on the alternative conventional energy sources [20]. Misra and Husain [21] has development an integrated hybrid renewable energy system based on duoale of inuducation generator for disperse generation of solar energy. However, in this study, simple integration of both potential of electricity from rice husk and that of electricity from solar was performed. The overall analysis and potential of integrated hybrid renewable energy system from the sources are explained in Fig. 8.

4.4 Road network analysis

Usually, road network models of lines are complex and can be analysed with network analysis in image processing software. Road network model is vital because it calculates the shortest path between the locations linked with the road network system. Ultimately, optimal route can be determined for the whole system and it minimizes the time duration and reduces the transportation cost and distance between the locations [22]. By using road network data for the study area and by using network analysis in image processing technique, optimal route for rice mill locations is obtained and shown in Fig. 9.

4.5 Site suitability for power plant location

By considering transportation, ground verification, land availability and price and environmental aspect, five locations are considered with the obtained classification and results, and within that, one feasible location is necessary to be proposed. By considering the optimal route for the study area, a particular feasible location is needed to be selected for placing an integrated hybrid renewable energy plant nearer to the rice mills cluster. So, finally with the overall assessment, the chosen location for integrated hybrid renewable energy system is 16° 44′ 52.93″ N latitude and 81° 42′ 43.51″ E longitude and it is shown in Fig. 10.

5 Conclusion

The technological trend towards renewable energy source utilization and cost reduction in industrial processing has been attracted with the wide usage of rice husk and solar energy as a value-added resource for the generation of electricity. High-resolution satellite data in image processing platform have been widely used for preciseness assessment for classifying land surface temperature. Integrated hybrid renewable energy system gives the enhanced reliability, security and resiliency for the electric grid. Within the optimal road network system, it is easy to transport the rice husk to the proposed power generation plant and along with that time duration, overall cost and distance between the locations reduce. Environmentally, this methodology and technical way of generating electricity will reduce the greenhouse emission gases. The main purpose is to assist the study area towards development and to establish integrated hybrid renewable energy power plant in rural areas of India.

References

Singh J (2016) Identifying an economic power production system based on agricultural straw on regional basis in Punjab. Renew Sustain Energy Rev 60:1140–1155

Esmaeili H, Farhadi M (2020) Prognosis of access to biomass residue resources in rural areas to provide energy for villagers. SN Appl Sci 1:1. https://doi.org/10.1007/s42452-020-2201-x

Sainu F, Mandla VR, Rao KM (2017) Urbanisation, energy consumption and emissions in the Indian context a review. Renew Sustain Energy Rev 71:898–907

Abedin MR, Das HS (2014) Electricity from rice husk: a potential way to electrify rural bangladesh. Int J Renew Energy Res 4:1–6

Brewer J, Ames Daniel P, Solan David, Lee Randy, Carlisle Juliet (2015) Using GIS analytics and social preference data to evaluate utility scale solar power site suitability. Renew Energy Int J 81:825–836

Ho WS, Hashimand H, Lim JS (2014) Integrated biomass and solar town concept for a smart eco village in Malaysia. Renew Energy 69:190–201

Kumar A, Mohanta K, Kumar D, Parkash Om (2012) Properties and industrial applications of rice husk: a review. Int J Emerg Technol Adv Eng 2:2250–2459

Panday B, Ajoy K (2016) Hydroelectric energy : renewable energy and the environment. CRC Press, NW

Phuangpornpitaka N, Tia S (2013) Opportunities and challenges of integrating renewable energy in smart grid system. Energy Procedia Eco Energy Mater Sci Eng Symp 34:282–290

Darling SB, You F, Veselka T, Velosa A (2011) Assumptions and the levelized cost of energy for photovoltaics. Energy Environ Sci R Soc Chem 4(9):3077–3704

Charabi Y, Gastli A (2011) PV site suitability analysis using GIS-based spatial fuzzy multi criteria evaluation. Renew Energy Int J 36:2554–2561

Bai Zhang, Liu Qibin, Lei Jing, Hong Hui, Jin H (2017) New solar-biomass power generation system integrated a two-stage gasifier. Appl Energy 194:310–319

Mofijur M, Mahlia TMI, Logeswaran J, Anwar M, Silitonga AS, Ashrafur Rahman SM, Shamsuddin AH (2019) Potential of rice industry biomass as a renewable energy source. Energies 12:4116

Garba NA, Zangina U (2015) Rice straw & husk as potential sources for mini-grid rural electricity in Nigeria. Int J Appl Sci Eng Res 4:523–530

Memon TA, Harijan K, Soomro MI, Meghwar S, Valasai GD, Khoharo H (2017) Potential of electricity generation from rice husk-a case study of rice mill. Sidha Univ Res J (Sci Ser) 49(3):495–498

Praveen Krishna S (2017) Geospatial models for an intergrated hybrid renewable energy systems—potential of electricity. Un-published Master thesis submitted at VIT University, Vellore, India

Loyd C (2016) Landsat 8 bands. NASA Landsat Sci 1–6

Khatri R (2016) Design and assessment of solar PV plant for girls hostel (GARGI) of MNIT University, Jaipur city: a case study. Energy Rep 2:89–98

Tiwari A et al (2009) Energy metrics analysis of hybrid—photovoltaic (PV) modules. Appl Energy 86:2615–2625

Waseem M, Sherwani AF, Suhaib M (2019) Integration of solar energy in electrical, hybrid, autonomous vehicles: a technological review. SN Appl Sci. https://doi.org/10.1007/s42452-019-1458-4

Misra NK, Husain Z (2019) An integrated hybrid renewable energy system based on doubly fed induction generator for disperse generation. In: Proceedings of the 4th international conference on innovations in automation and mechatronics engineering (ICIAME2018), pp 106–112. ISBN: 978-1-78985-297-4

Fernandez RD (2014) A GIS model of the national road network in Mexico. Res Transp Econ 46:36–54

Acknowledgements

Authors would like to thank the editor and anonymous reviewers for their valuable comments on the manuscript.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sannidhi, P.K., Mandla, V.R., Saladi, S.S.V. et al. An integrated hybrid renewable energy system: potential of electricity—a geospatial approach. SN Appl. Sci. 2, 1642 (2020). https://doi.org/10.1007/s42452-020-03329-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-020-03329-2