Abstract

This work highlights recent developments in understanding human body odour with particular attention to natural fibres used in next-to-skin textiles: fibre type and fabric structure affecting patterns of adsorption and release of volatile organic compounds known as contributing to body odour; methods for detection and judging intensity of odour; and effects of environmental pressures which impinge on cleaning textiles and its efficacy. That the type of fibre has a dominant effect on adsorption and release of volatile organic compounds is a common finding from multiple and varied investigations. Ranking body odour retained in textiles from least intense to most intense—wool, cotton, polyester/polyamide—is reasonably consistent irrespective of method. Blends of different fibres and re-use/up-cycling warrant investigation with respect to adsorption and release of volatile organic compounds.

Similar content being viewed by others

1 Human body odour: source and textiles

Natural fibres are sought for manufacture to many types of products, including apparel worn next to the skin, notwithstanding the dominance of synthetic fibres/filaments in these and other applications. An issue of increasing interest with this product group is understanding and better managing the development, retention, and removal of volatile organic compounds (VOCs) present in worn/used fabrics. The principal reasons for this are environmental, the personal environment of individuals (i.e. to be odour-free) and broad environmental issues (e.g. sustainability in production and use of fibre-based products, reduced use of energy and water in cleaning). This review of recent published papers and related grey literature integrating different elements of the topic is thus timely.

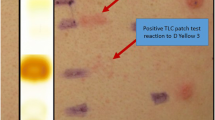

The origin of human body odour has been explained in several publications (e.g. [1,2,3]) physiological secretions (sweat, sebum) and epithelial cells shed from the skin surface along with microbiological flora of the skin, are absorbed and/or fixed by adjacent fabrics; interactions among these leading to development of VOCs many of which are adsorbed/released over time. The presence of VOCs on or in fibres/textiles and patterns of adsorption and release can be determined instrumentally (proton transfer reaction-mass spectrometry (PTR-MS), solid-phase micro-extraction followed by gas chromatography–mass spectrometry (SPME-GC/MS), gas chromatography–mass spectrometry/olfactometry (GC–MS/O)/GC–O), Time-resolved (TR) spectrometry), as well as sensorially (trained human panels, consumer groups). Complementary information is provided by each, instrumental methods allowing identification of the presence of chemical constituents, and humans determining the minimum detection levels, ranking of intensity, and acceptability or not.

Differences attributable to fibre type and fabric structure, and malodour and apparel cleaning practices are considered. Although minimising development of malodour in fibres/textiles by application of antimicrobial treatments, and masking by application of fragrance or oils are both possible, these topics have been excluded.

2 Differences attributable to fibre type and fabric structure

Published and un-published research on adsorption and release of odour volatiles has focussed on fibres and fabrics common for next-to-skin products (e.g. cotton, wool, polyester, polyamide (nylon)). Table 1 provides key features of garments, fabrics, and yarns; Table 1a, where the source of the VOCs was the human body, and Table 1b, where a selection of VOCs from those known to be present in human body odour was made by the investigator, some as a matrix and some as single VOCs. (Note that hundreds of volatiles have been identified as constituents of human body odour and relevant to the human skin [4].) What is clear from the table is that interest in odour and textiles has continued for more than 2 decades, with differences in the fibre/fabric model used (e.g. garments such as socks and t shirts worn, swatches of fabrics of known properties stitched to the underarm of a t shirt and worn, standard fabrics (e.g. [5, 6]) disaggregated to yarn bundles and exposed to volatiles under laboratory conditions). These differences contribute to complexity in comparing results from the various investigations. Use of standard fabrics more recently is facilitating comparison of findings and replication of investigations. Differences in volatiles selected, periods of incubation, temperature, and in methods of detection are also evident.

Viscose, part of the group of cellulosic-based man-made fibres [7] (around 8% of man-made fibres in 2017 [8]) is expected to increase for apparel and other applications given the present trend [9] and that its source is renewable. Preliminary findings of our current work on viscose suggests, in general, viscose and cotton exhibit similar responses to VOCs, but that there are individual VOCs where viscose has a higher adsorption with the same release (i.e. phenol), or where viscose has a higher release when showing the same adsorption capability as cotton (i.e. 1-octanol) (Richter et al. 2019, personal communication). Blends of different fibre types are also being investigated. A recent report on blending wool with polyester [10] showed an optimum blend which would minimise undesirable odour typical of 100% polyester (20% wool, 80% polyester), thus suggesting the approach could be useful in optimisation. No research on VOCs adsorbed by or emitted from fabrics made from recycled materials has been identified notwithstanding interest in this and the ‘new’ forms of fibres/textiles.

Table 1a shows the natural fibres wool and cotton, have been commonly compared with synthetic fibres polyester and polyamide, and although varied conditions under which the comparisons were made, the order of intensity of odour (least to most) is remarkably consistent: natural fibres, especially wool, exhibited the least intense odour. Table 1b, where investigators selected VOCs (Table 1b), fibre-related results are similar. Thus, there is evidence supporting wool fabrics being considered low odiferous: the approximate decreasing order of odour intensity being wool < cotton < viscose < linen < polyester/polyamide. The mechanisms involved are not fully understood partly because of confounding factors such as fabric structure (affecting absorption of moisture and drying behaviour; thermal properties) and the way in which elements of the skin microbiome (i.e. bacteria, archaea, fungi) may be hosted and fixed to fabrics. This highlights the importance of fabric structure.

Table 2 summarises the few investigations in which yarns and fabric structures have been the focus. This limited interest in fabric structure is not surprising given the challenge of securing test fabrics varying only in fibre content: use of standard fabrics is a useful option. However, given several fabric structural and performance properties are linked to odour (e.g. thickness, mass per unit area, sett, moisture absorption, thermal resistance), omission of fabric structural description in some investigations inhibits clarity in understanding (e.g. [3]).

3 Malodour and apparel cleaning practices

3.1 Efficacy of cleaning, and trends in reduced wash temperature and water volume

Table 3 provides detail on a range of specifications for domestic clothes washers used in Western parts of Europe, in the Americas, and in Australia and New Zealand. The table shows differences in requirements across different geographic regions, based on two groups of standards IEC/EN—horizontal-axis washing machines (Europe) and ANSI/AHAM—vertical-axis washing machines (the Americas). Differences exist in water temperature (e.g. in western Europe, the water temperature for machine washing is typically 60 °C +) and in determination of performance. For example, the standard for cleaning performance of domestic washing machines sold in Australasia requires compliance with change to soiling/stain only, determined instrumentally [22].

Any in-progress changes in specification, design and manufacture of machines for domestic washing have direct relevance to the efficacy of the cleaning process, including whether or not removal of odour volatiles (and microorganisms) forms part of what is measured. Manufacturers of washing machines continue efforts to design products which perform with reduced energy and water (i.e. lower water temperature, less water), and need to take account of these additional performance measures.

The extent to which cleaning practices are effective in removing volatiles has been explored, related to both product type and fibre. One study on worn socks (74% cotton, 19% polyester, 5% nylon, 2% elastane) and t shirts (100% polyester) were washed at 20 °C, with effective reduction in VOC concentrations on socks when both dry and damp, but malodour was reduced by 25–98% with the t shirt. The authors intimated some reduction was related to evaporation of these volatiles, and that there was a potential link with bacteria known to be present in the axillary region [25]. With socks (polyester) as a model and two VOCs (dimethyl disulfide, dimethyl trisulfide), Denawaka et al. showed washing at a higher temperature (50 °C) was more effective at removing these two VOCs than washing at a lower temperature (20 °C). Use of softeners in washing to enhance handle and reduce static electricity of textiles is common, however, softeners have been shown to increase odour on polyester garments over several cycles of use, washing, and airing [26]. The presence and removal of sebum from human contact with textiles has recently also been investigated with promising results of a new test method [27].

3.2 Duration of use/wear and perception of need to wash an item

The frequency of cleaning and perception of the need to clean are also of interest (e.g. [28,29,30]). There are at least two reasons; first, to reduce use of both energy and water, and second, to reduce fibre loss from the product during cleaning (resulting in reduced fibre released to waterways and an extension to product life). The frequency of washing clothing/textiles after use is determined largely by product category (i.e. outerwear/jackets, knitwear, next-to-skin, underwear). In this context, understanding effects of cleaning and the need for cleaning, life cycle analyses (LCA) and life cycle impact assessment (LCIA) have focussed on fibre types.

Cotton, polyester, nylon, acrylic, and elastane have been compared in terms of production to base material (i.e. extraction of raw material, processing to a textile (knitting, weaving, finishing) but excluding manufacture and use of consumer products, and some aspects of discarded textiles [31]. Ranking of fibres from that investigation from least to most environmental impact was acrylic < polyester < elastane < nylon < cotton. A more recent comparison of environmental impacts of different fibres highlighted the connection between the fibre content of a product and use and care, indicating distortionary effects of omitting product lifespan, quality, and function [32]. Consumers from several countries (e.g. Norway, UK, Netherlands, Sweden, Finland) reportedly use fibre type and properties common in product groups in deciding on the need to wash. The lifespan of selected garments across these countries was estimated as (years (range)): socks 2.6 (1.8–3.6), underwear 3.1 (2.4–4.4), jeans 3.5 (2.5–4.3), t shirts 4.6 (3.3–6.8), sweaters 6.0 (3.7–10.8), jackets/blazers 6.8 (4.0–11.5) [32]. Also considering differences in end use, an Australian-based investigation of environmental effects of the textile supply chain used the LCA of three items of apparel differing in fibre content (cotton knit shirt, polyester knit shirt, wool sweater) and considered climate change as the impact category with all phases of manufacture and use (washing, drying, ironing; end of life disposal) included. In terms of use, the order of impact least to most was wool < cotton < polyester, largely attributable to the type of garment [33]. Change in behaviour of end users (e.g. water and energy in washing and drying), changed transport (air, sea freight), and inclusion of recycling in the LCA model, along with avoidance of selected products, were additions to the model to better estimate the environmental impact of the textile supply chain from extraction to end of life.

4 Conclusions and recommendations

This review highlights key issues in recent research on odour and next-to-skin textiles. There are four issues:

-

1.

In terms of fibre-based differences, the behaviour of common natural fibres such as wool and cotton in relation to odour is reasonably well established. However, more investigation is needed on a wider range of natural fibres, on man-made cellulosics (e.g. viscose), and on up-cycled/recycled sources. Establishing blends by selecting fibres known to minimise odour seems feasible using instrumental and sensory methods to determine the presence, quality, and intensity of odour.

-

2.

Effects of fabric structure on patterns of adsorption and release of odour volatiles continues to be poorly understood. This warrants further investigation using standard fabrics (and yarns), as this facilitates replication of experimental work, aids understanding by the international scientific community, and provides underpinning for legitimate product marketing.

-

3.

Both fibre type and fabric structure influence product end function, with function characterised by different exposures, duration of use, frequency of cleaning, and decisions in relation to disposal/re-use. Odour volatiles are inextricably linked to each of these, and need to be understood if fibre-based claims of environmental impact are to be defended.

-

4.

Given the international trend to conserve water and energy leading to domestic washing at a lower temperature and with less water, evidence of effects of these changes on efficacy of cleaning will be required. Further, the criteria for determining this efficacy warrants inclusion of evidence of VOC reduction.

References

Prada PA, Curran AM, Furton KG (2014) Characteristic human scent compounds trapped on natural and synthetic fabrics as analyzed by SPME-GC/MS. J Forensic Sci Criminol 1(1):1–10. https://doi.org/10.15744/2348-9804.1.S101

McQueen RH, Laing RM, Delahunty CM, Brooks HJL, Niven BE (2008) Retention of axillary odour on apparel fabrics. J Text Inst 99(6):515–523. https://doi.org/10.1080/00405000701659774

Callewaert C, De Maeseneire E, Kerckhof F-M, Verliefde A, Van de Wiele T, Boon N (2014) Microbial odor profile of polyester and cotton clothes after a fitness session. Appl Environ Microbiol 80(21):6611–6619. https://doi.org/10.1128/AEM.01422-14

Gallagher M, Wysocki CJ, Leyden JJ, Spielman AI, Sun X, Preti G (2008) Analyses of volatile organic compounds from human skin. Br J Dermatol 159(4):780–791. https://doi.org/10.1111/j.1365-2133.2008.08748.x

Testfabrics I (2019) Testfabrics https://www.testfabrics.com/. Accessed 24 May 2019

Introtech Limited (2019) James Heal Consumables. http://www.itloffice.com/materials_detail/3. Accessed 24 May 2019

International Organization for Standardization (2013) ISO 2076: 2013 E textiles—man-made fibres—generic names. In: International Organization for Standardization, Geneva, Switzerland, vol 6

Textile Outlook International (2018) Global trends in fibre prices, production and consumption. Textile Outlook International, vol 191, no April, p 71

Textile Outlook International (2017) Global trends in fibre prices, production and consumption. Textile Outlook International, vol 188, no October, p 81

Wang J, Lu X, Wang J, Wang X (2019) Quantitative and sensory evaluation of odor retention on polyester/wool blends. Text Res J 89(13):2729–2738. https://doi.org/10.1177/0040517518801183

Abdul-Bari MM, McQueen RH, Nguyen H, Wismer WV, de la Mata AP, Harynuk JJ (2018) Synthetic clothing and the problem with odor: comparison of nylon and polyester fabrics. Cloth Text Res J 36(4):251–266. https://doi.org/10.1177/0887302X18772099

de la Mata AP, McQueen RH, Nam SL, Harynuk JJ (2017) Comprehensive two-dimensional gas chromatographic profiling and chemometric interpretation of the volatile profiles of sweat in knit fabrics. Anal Bioanal Chem 409:1905–1913. https://doi.org/10.1007/s00216-016-0137-1

McQueen RH, Harynuk JJ, Wismer WV, Keelan M, Xu Y, de la Mata AP (2014) Axillary odour build-up in knit fabrics following multiple use cycles. Int J Cloth Sci Technol 26(4):274–290. https://doi.org/10.1108/IJCST-05-2013-0064

Rathinamoorthy R, Thilagavathi G, Brindha S, Gayathri P, Poornakala NS, Pradeep B (2014) Odour control studies on apparel fabrics finished with methanol extract of Terminalia chebula. Fibers Polym 15(8):1669–1676. https://doi.org/10.1007/s12221-014-1669-7

McQueen RH, Laing RM, Wilson CA, Niven BE, Delahunty CM (2007) Odor retention on apparel fabrics: development of test methods for sensory detection. Text Res J 77(9):645–652. https://doi.org/10.1177/0040517507078792

McQueen RH, Laing RM, Brooks HJL, Niven BE (2007) Odor intensity in apparel fabrics and the link with bacterial populations. Text Res J 77(7):449–456. https://doi.org/10.1177/0040517507074816

Burling-Claridge GR (1998) Odour production in active sportswear. WRONZ, Christchurch

Richter TM, Bremer PJ, Silcock P, Laing RM (2017) Textile binding and release of body odor compounds measured by proton transfer reaction—mass spectrometry. Text Res J 88(22):2559–2567. https://doi.org/10.1177/0040517517725126

Yao L, Laing RM, Bremer PJ, Silcock PJ, Leus MJ (2015) Measuring textile adsorption of body odor compounds using proton-transfer-reaction mass spectrometry. Text Res J 85(17):1817–1826. https://doi.org/10.1177/0040517515576325

Hammer TR, Berner-Dannenmann N, Hoefer D (2013) Quantitative and sensory evaluation of malodour retention of fibre types by use of artificial skin, sweat and radiolabelled isovaleric acid. Flavour Fragr J 28(4):238–244. https://doi.org/10.1002/ffj.3134

Abdul-Bari M, McQueen R (2016) Comparison of odor intensity between nylon and polyester. In: International Textile and Apparel Association (ITAA) annual conference proceedings, Vancouver, BC, vol 132. ITAA, pp 1–3. https://lib.dr.iastate.edu/itaa_proceedings/2016/posters/132

Standards Australia and Standards New Zealand (2005) AS/NZS 2040 2005 performance of household electrical appliances—clothes washing machines. Standards Australia and Standards New Zealand, Sydney Australia, Wellington, New Zealand

Barthel C, Gotz T (2013) Test procedures, measurements and standards for domestic washing machines. Appliances guide. Wuppertal Institute for Climate, Environment and Energy, Wuppertal

European Committee for Standards—Electrical (2016) EN 60456:2016 Clothes washing machines for household use—methods for measuring the performance (IEC 60456:2010, modified). European Committee for Standards—Electrical, Brussels, Belgium

Denawaka CJ, Fowlis IA, Dean JR (2016) Source, impact and removal of malodour from soiled clothing. J Chromatogr A 1438:216–225. https://doi.org/10.1016/j.chroma.2016.02.037

Laitala K, Kjeldsberg M, Grimstad Klepp I (2012) Troubles with the solution: fabric softeners and odour properties. Tenside Surfactants Deterg 49(5):362–368. https://doi.org/10.3139/113.110203

Krifa M, Rajaganesh S, Fahy W (2019) Perspectives on textile cleanliness—detecting human sebum residues on worn clothing. Text Res J 89(23–24):5226–5237. https://doi.org/10.1177/0040517519855323

Collins M, Aumônier S (2002) Streamlined life cycle assessment of two marks & Spencer plc apparel products. Environmental Resources Management, Oxford

Arild A, Brusdal R, Tore J, Halvorsen Gunnarsen JT, Terpstra PMJ, van Kessel IAC (2003) An investigation of domestic laundry in Europe: habits, hygiene and technical performance. National Institute for Consumer Research, Oslo

McQueen RH, Batcheller JC, Moran LJ, Zhang H, Hooper PM (2017) Reducing laundering frequency to prolong the life of denim jeans. Int J Consum Stud 41:36–45. https://doi.org/10.1111/ijcs.12311

van der Velden N, Patel M, Vogtländer J (2014) LCA benchmarking study on textiles made of cotton, polyester, nylon, acryl, or elastane. Int J Life Cycle Assess 19(2):331–356. https://doi.org/10.1007/s11367-013-0626-9

Laitaila K, Klepp IG, Henry B (2018) Does use matter? Comparison of environmental impacts of clothing based on fiber type. Sustainability 10(7):2524–2548. https://doi.org/10.3390/su10072524

Moazzem S, Daver F, Crossin E, Wang L (2018) Assessing environmental impact of textile supply chain using life cycle assessment methodology. J Text Inst 109(12):1574–1585. https://doi.org/10.1080/00405000.2018.1434113

Acknowledgements

The author acknowledges present and former colleagues, research students, and participants who have contributed to better understanding of this field.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author declares no conflict of interest.

Ethical approval

Where research was conducted at the University of Otago, New Zealand, all ethical requirements of that university were met.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Laing, R.M. Natural fibres in next-to-skin textiles: current perspectives on human body odour. SN Appl. Sci. 1, 1329 (2019). https://doi.org/10.1007/s42452-019-1388-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-019-1388-1