Abstract

The biowaste curd water generated after the curd formation was utilized as an acid catalytic green solvent for the synthesis of 3,3-bisindolylmethanes derivatives. The soluble organic acid (i.e. lactic acid) responsible for the acidity to curd water which adequately fulfills the purpose of acid catalyzed reaction, where 2 mol of indole reacted with an aldehyde in the presence of curd water at a low temperature and yields classical 3,3-bisindolylmethanes derivatives. During the reaction, continuous product formation and isolation was observed. The product precipitate was separated by the successive method of filtration. This biowaste water catalyzed method is highly retrievable and advantageous over the trend of high-temperature inorganic acid catalyzed reaction offering the effortlessly separable product.

Graphic abstract

Similar content being viewed by others

1 Introduction

Since the solvent and catalyst are the key component of organic reaction, a challenge of benign solvent and acid catalyst is an agenda of green chemical synthesis. Specific features of green chemistry such as benign by design sustainable products, environmental friendliness, easy separation, low preparation cost, high selectivity, low temperature are required for the true practice of green chemistry. ‘Green chemistry’ is the principal and multi-dynamic field in chemistry [1,2,3]. The use of the ideologies of green chemistry can be evaluated for the sustainability of synthetic protocols [4]. Several synthetic methodologies have been carried out in green solvents in recent years, showing most superior efficiency and selectivity than those performed in conventional organic solvents [5]. In the last 15 years, new nonconventional solvent alternatives attracted the attention and began to change the practise of conventional solvents. List of the benign and green solvents includes water, ionic liquids, organic carbonates, alcohols, as well as bio-solvents [6]. The reduction of the use of solvent involves either making fully solvent-free or use of innocuous solvents with recycling ability. In this respect, use of clean and neat reaction [7] and using water as solvent [8] or water substituted media [9] is favoured. Unique reaction protocol involves high reactive selectivity as well as better separation and purification ability of the final product. In addition, the true green chemical reaction is achieved by practising atom economy [10] and step economy principal for designing more professional synthetic technological process [11].

Curd is a dairy product prepared by curdling using edible acidic substance like lemon juice or vinegar. The remained draining homogeneous liquid after curd formation includes some soluble low molecular weight acidic proteins [12]. Lactobacillus in milk sample triggered and multiplied by the addition of old curd culture at an ambient temperature 30–40 °C [13, 14]. Yogurt/Dahi (Indian term) is regularly consumed food material and a rich source of protein. Curd water is waste material obtained after curd and yogurt separation, which is commonly known as whey [15]. Curd water is pale yellow color homogeneous low molecular weight proteinaceous liquid material [16]. We have previously demonstrated the synthesis of 3-carboxycoumarins at room temperature in banana peels extract water [17]. The 3,3-bisindolylmethanes is present in many natural products having significant bioefficacy [18]. Therefore, a number of procedures for the preparation of bisindolylmethane derivatives have been reported in the literature, using the action of indole with various aldehydes and ketones in the presence of either a Lewis acid or Bronsted acid [19]. In continuation of that, we have developed a simple and efficient protocol for the synthesis of the label 3,3-bisindolylmethanes compounds. The homogeneous curd water solution acts as a solvent, offering decent reaction productivity. The underutilized non-conventional solvent further encourages investigation of efficient green synthetic protocols which overcome some inherent disadvantages cited.

2 Results and discussions

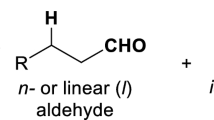

One-pot synthesis has been known for the synthesis of several complex organic entities in pharmaceuticals industries [17]. Various methodologies have been tried for this one-pot synthesis, using different organic acids catalyst [20]. The other organic acids like citric acid, tartaric acid, oxalic acid have been reported as a catalyst for the synthesis of various important chemical reactions [21]. Apart from this conventional source, some biological materials like banana peel biowaste water extract have been already reported in the earlier study for various reactions [22, 23]. In continuation to that, with best of our knowledge, the reaction of 2 mol of indoles (1) and 1 mol of aldehydes (2) was never reported under catalyst-free conditions in curd water. We considered here, the reaction of 2 mmol indoles (1) and 1 mol aldehyde (2) as a typical model reaction. Further, the methodology was extended for the synthesis of various 3,3-bisindolylmethanes derivatives. Thus, a high yield of 3,3-bisindolylmethanes (75–88%) was obtained (Table 2) in the presence of curd water liquid. Curd water is a homogeneous, stable, non-dispersed solution exists for a long time without segregation overcoming the general problem of precipitation. The lactic acid content in the curd water was confirmed for its presence quantitatively by the standard method of analysis. The lactic acid induced acidity was determined by the digital pH meter as well as by the titration method with 0.1 N NaOH. The lactic acid present in the curd water solution is responsible for the quantitative conversion of final compounds 3a–3j (Table 1). Lactic acid imparts sufficient accessible acidity to the solution which accelerates the conversion of indole and aldehyde. It is worth observing that this work is an input to the green chemistry protocol since the method is environmentally benign. This method was further extended and optimized for scope compounds (3a–3j), which were easily separated. 1H NMR and IR spectra characterization confirm the formation of the final product. The presence of lactic acid truly influences the formation of the final product as depicted in the Reaction Scheme. The reaction sequence is depicted in the Reaction Scheme started with the polarisation of benzaldehyde with the induced acidity of lactic acid (a). Further nucleophilic substitution reaction of indole on electron deficient carbonyl carbon of substituted benzaldehyde occurs (b). Further, the subsequent loss of proton adds the indole substituent on substituted benzaldehyde (c). The intermediate (b) forms in the vicinity of lactic acid, which is responsible for polarisation of (c) ready to react further with another mole of indole forms (d). Similar nucleophilic substitution reaction occurs with another mole of indole with loss of water molecule to generate 3,3-bisindolylmethanes (e). Several substituted aromatic aldehydes undergo an electrophilic substitution reaction smoothly with indole, to afford a wide range of substituted 3,3 bis(indolyl)methanes with excellent yields. This method is also effective for aldehydes bearing electron-donating and electron -withdrawing functional group.

2.1 Physico-chemical properties of curd water

The physicochemical properties of the curd water like pH, total acidity, total carbohydrate, and total protein contents were analyzed by standard methods. The pale colour water was derived from curd and subjected to determine the pH by digital pH meter (HANNA, instruments). The total acidity (Titrable acidity) was determined by titration of curd water against the 0.1 N NaOH solution with phenolphthalein indicator, and the total acidity was expressed in percent (% lactic acid) by using the following formula [24].

The total carbohydrate and protein were estimated by Phenol sulphuric acid [25] and Biuret method [26], respectively, and the contents were calculated in gram % by using standard graphs (S1). The physicochemical parameters of curd water were determined, as shown in Table 1. The total acidity, carbohydrate, and protein were found to be 1.20 ± 0.01 (%), 0.22 ± 0.03 and 1.22 ± 0.03 (g%), respectively. The titrable acidity was higher than the milk due to lactic acid fermentation, which plays a vital role in the acceleration of organic reactions like condensation, ring transformations, and multicomponent reactions. The low percentage of carbohydrates indicates the conversion of milk sugar into lactic acid.

3 Experimental

3.1 Procedure for the preparation of curd water solvent

The curd was prepared in the laboratory using the 1% of Lactic acid bacteria starter culture in 100 ml pasteurized warm milk in aseptic condition and incubated at 37 °C for 48 h for activation of the culture to set the curd. The water from the freshly prepared curd was removed with a muslin cloth and turbid liquid was collected. The turbid liquor was centrifuged at 4000 rpm for 15 min and filtered to collect the liquor using ordinary Whatman paper. This pale-yellow color liquid was applied for further reaction.

3.2 Synthetic procedures

Initially, 2 mmol of indole and 1 mol substituted benzaldehyde was properly mixed in RBF. 10 mL of curd water was added and stirred the reaction mixture at room temperature. The progress of the reaction was monitored by TLC. Product formation was observed, and the insoluble final product was crystallized itself in the reaction mixture. After completion of the reaction in necessitating time, the final product was separated by subsequent filtration and washed with a required amount of hot distilled water. Further product was recrystallized in methanol.

Further product was recrystallized in methanol. 1H NMR (400 MHz) NMR spectra were recorded in DMSO-d6 on Bruker AV-400 and Bruker DPX 400 MHz spectrometer with the presence of chemical shifts and reported in parts per million (d) relative to internal standard tetramethylsilane. IR spectra were obtained as mineral- oil mulls on a Spekord N80 spectrophotometer in the frequency of absorption (cm−1).

3,3′-((4-nitrophenyl) methylene) bis(1H-indole) (3a): 1 H NMR

(400 MHz, DMSO d6): δ (ppm) 10.96 (s, 2H), 8.15 (d, J = 8 Hz, 2H), 7.61 (d, J = 8 Hz, 2H), 7.37 (d, J = 8 Hz, 2H), 7.30 (d, J = 8 Hz, 2H), 7.06 (t, J = 8 Hz, 2H), 6.95–6.76 (m, 4H), 6.04 (s, 1H);IR ν (cm−1) (KBr): 3373, 2962, 1602, 1431.

3,3′-((4-chlorophenyl) methylene)bis(1H-indole) (3b): 1 H-NMR

(400 MHz, DMSO d6): δ (ppm) 10.84 (s, 2H), 7.36–7.32 (m, 4H), 7.31 (d, J = 8 Hz, 2H), 7.27 (d, J = 8 Hz, 2H), 7.06 (t, J = 8 Hz, 2H), 6.88 (t, J = 8 Hz, 2H), 6.83 (s, 2H), 5.86 (s, 1H). IR ν (cm−1) (KBr): 3383, 2962, 1602, 1446.

3,3′-((2-bromophenyl) methylene)bis(1H-indole) (3c): 1 H-NMR

(400 MHz, CDCl3): δ (ppm) 7.86 (s, 2H), 7.26–7.46 (m, 5H), 7.19 (s, 1H), 7.16 (d, J = 8 Hz, 1H), 7.12–7.05 (m, 2H), 7.04–7.00 (m, 1H), 6.96 (t, J = 8 Hz, 2H), 6.55 (s, 2H), 6.27 (s, 1H). IR ν (cm−1) (KBr): 2954, 1606, 1440, 1033.

3,3′-(p-tolylmethylene) bis(1H-indole) (3d): 1 H-NMR

(400 MHz, CDCl3): δ (ppm) 7.91 (s, 2H), 7.39 (d, J = 8 Hz, 2H), 7.35 (d, J = 8 Hz, 2H), 7.22 (d, J = 8 Hz, 2H), 7.16 (t, J = 8 Hz, 2H), 7.06 (d, J = 8 Hz, 2H), 7.00 (t, J = 8 Hz, 2H), 6.66 (s, 2H), 5.85 (s, 1H), 2.31 (s, 3H). IR ν (cm−1) (KBr): 3321, 2960, 1602, 1431.

2-(di(1H-indol-3-yl) methyl)phenol (3e): 1 H-NMR

(400 MHz, CDCl3): δ (ppm) 7.90 (s, 2H), 7.39 (d, J = 8 Hz, 2H), 7.35 (d, J = 8 Hz, 2H), 7.22 (d, J = 8 Hz, 2H), 7.16 (t, J = 8 Hz, 2H), 7.08 (d, J = 7.7 Hz, 2H), 7.00 (t, J = 8 Hz, 2H), 6.65 (s, 2H), 5.85 (s, 1H), 2.30 (s, 3H).IR ν (cm−1) (KBr): 3324, 2960, 1604, 1431.

3,3′-((4-methoxyphenyl) methylene)bis(1H-indole) (3f): 1 H-NMR

(400 MHz, CDCl3): δ (ppm) 7.92 (s, 2H), 7.38 (d, J = 8 Hz, 2H), 7.34 (d, J = 8 Hz, 2H), 7.24 (d, J = 8 Hz, 2H), 7.16 (t, J = 8 Hz, 2H), 7.00 (t, J = 8 Hz, 2H), 6.80 (d, J = 8 Hz, 2H), 6.63 (s, 2H), 5.83 (s, 1H), 3.75 (s, 3H). IR ν (cm−1) (KBr): 2962, 1602, 1456, 1280.

4-(di(1H-indol-3-yl) methyl)-2-methoxyphenol (3g): 1 H-NMR

(400 MHz, CDCl3): δ (ppm) 7.85 (s, 2H), 7.38 (d, J = 7.9 Hz, 2H), 7.30 (d, J = 8.1 Hz, 2H), 7.15 (t, J = 7.6 Hz, 2H), 6.99 (t, J = 7.5 Hz, 2H), 6.87 (s, 1H), 6.83–6.74 (m, 2H), 6.58 (s, 2H), 5.79 (s, 1H), 3.72 (s, 3H). IR ν (cm−1) (KBr): 3201, 2964, 1606, 1404, 1045.

2-(di(1H-indol-3-yl) methyl)-3-isopropyl-6-methylphenol (3h): 1 H NMR

(400 MHz, CDCl3) δ (ppm) 1.22 (d, J = 4.0 Hz, 6H), 2.09 (s, 3H), 3.36–3.42 (m, J = 4.0 Hz, 1H), 6.28 (s, 1H), 6.30 (d, J = 8.0 Hz,1H), 6.71 (s, 2H), 6.89 (d, J = 8.0 Hz, 1H), 6.70 (d, J = 8.0 Hz, 2H), 7.06 (s, 1H), 7.17 (dd, J = 8.0 Hz, 1H), 7.23 (dd, J = 8.0 Hz, 1H) 7.31 (d, J = 8.0 Hz, 2H), 7.33 (d, J = 8.0 Hz, 2H), 7.93 (s, 2H).IR ν (cm−1) (KBr): 3395, 3048, 2950, 2345, 1595, 1433, 750.

2-(di(1H-indol-3-yl) methyl)-6-isopropyl-3-methylphenol (3i): 1 H NMR

(400 MHz, CDCl3) δ (ppm) 1.13 (d, J = 4.0 Hz, 6H), 2.42 (s, 3H), 3.08–3.15 (m, J = 4.0 Hz, 1H), 6.13 (s, 1H,), 6.25 (d, J = 8.0 Hz, 1H), 6.72 (s, 2H), 6.81 (d, J = 8.0 Hz, 1H), 6.83 (d, J = 8.0 Hz, 2H), 7.06 (s, 1H), 7.17 (dd, J = 8.0 Hz, 1H), 7.21 (dd, J = 8.0 Hz, 1H),7.24 (d, J = 8.0 Hz, 2H), 7.32 (d, J = 8.0 Hz, 2H), 7.92 (s, 2H).IR ν (cm−1) (KBr): 3395, 3048, 2950, 2345, 1595, 1433, 750.

4-allyl-2-(di(1H-indol-3-yl) methyl)-6-methoxyphenol (3j): 1 H NMR

(400 MHz, CDCl3) δ (ppm) 3.11 (d, J = 12 Hz, 2H), 3.77 (s, 3H), 4.90–4.94 (m, 2H), 5.69 (s, 1H), 5.79–5.85 (dd, J = 12 Hz, 1H), 6.21 (s, 1H), 6.51 (d, J = 8.0 Hz, 2H), 6.53 (d, J = 8.0 Hz, 2H), 6.93–6.97 (m, 2H), 7.06–7.10 (m, 2H), 7.18 (s, 2H), 7.39 (d, 1H), 7.41(s, 1H), 7.58 (s, 2H).IR ν (cm−1) (KBr): 3455,3065, 3413, 3054, 2496, 1611, 1428, 924.

3.3 Reusability study

Reuse of the catalyst during every cycle of reaction is the symbol of decreasing environmental pollution. The reusability of the curd water containing catalyst was studied in the reaction of 4-nitrobenzaldehyde and indole in curd water at room temperature with continues stirring. After each cycle, the catalyst was recovered by simple filtration. Due to the washing of the final product with water, the mother liquor was diluted, the recovered dilute mother liquor was reused three times, result in the loss of its activities (Table 2). After three cycles, the use of such catalyst resulted in a lower yield of the product. It will not be significant enough for continuous use, many washing of distilled water reduces its acidity (Table 3).

Reaction Scheme

Plausible Mechanism

4 Conclusion

The present study introduced the new synthetic protocol for 3,3-bisindolylmethane derivatives, where lactic acid induced acidity provides the catalytic support for the given reaction. The homogeneous reaction condition was achieved, and product separation by precipitation was attained. The synthetic route defined here offers an alternative to the available method for the preparation of 3,3-bisindolylmethane derivative. This reaction is advantageous over the high temperature synthesis and tedious product separation from the reaction mixture. The catalyst free condition is a major advantage of bio-waste liquid material, achieving a green alternative to the existing protocols. This biowaste curd water is a potential solvent to similar industrially applied reactions.

References

Mahire VN, Mahulikar PP (2015) Facile one-pot clean synthesis of benzimidazole motifs: exploration on bismuth nitrate accelerated subtle catalysis. Chin Chem Lett 26(8):983–987

Anastas P, Eghbali N (2010) Green chemistry: principles and practice. Chem Soc Rev 39(1):301–312

Anastas PT, John CW (1998) Green chemistry: theory and practice. Oxford University Press, Oxford

Collins TJ (1995) Introducing green chemistry in teaching and research. J Chem Educ 72(11):9964–9965

Suresh, Sandhu JS (2011) Recent advances in ionic liquids: green unconventional solvents of this century: part I. Green Chem Lett Rev 4(4):289–310

Suresh, Sandhu JS (2011) Recent advances in ionic liquids: green unconventional solvents of this century: part II. Green Chem Lett Rev 4(4):311–320

Zhang Y, Dubé MA (2017) Green emulsion polymerization technology. In: Pauer W (ed) Polymer reaction engineering of dispersed systems. Springer, Cham, pp 65–100

Azizi N, Torkian L, Saidi MR (2007) Highly efficient synthesis of bis(indolyl)methanes in water. J Mol Catal A Chem 275(4):109–112

Aparicio S, Alcalde R (2009) The green solvent ethyl lactate: an experimental and theoretical characterization. Green Chem 11(1):65–78

Moores A (2010) Atom economy–principles and some examples. In: Handbook of green chemistry. pp 1–15

Vemula PK, John G (2008) Crops: a green approach toward self-assembled soft materials. Acc Chem Res 41(6):769–782

Shah NP, Lankaputhra WE (1997) Improving viability of Lactobacillus acidophilus and Bifidobacterium spp. in yogurt. Int Dairy J 7(5):349–356

Walstra P (1999) Dairy technology: principles of milk properties and processes. CRC Press, Boca Raton

Walstra P, Geurts TJ, Walstra P, Wouters JT (2005) Dairy science and technology. CRC Press, Boca Raton

Amatayakul T, Halmos AL, Sherkat F, Shah NP (2006) Physical characteristics of yoghurts made using exopolysaccharide-producing starter cultures and varying casein to whey protein ratios. Int Dairy J 16(1):40–51

Modhu AL (2016) Development of good quality of yogurt in terms of texture, flavor, food value and low cost and determining the fat percentage of milk and yogurt. Doctoral dissertation, BRAC University

Gein VL, Zamaraeva TM, Slepukhin PA (2014) A novel four-component synthesis of ethyl 6-amino-4-aryl-5-cyano-2, 4-dihydropyrano [2,3-c] pyrazole-3-carboxylates. Tetrahedron Lett 55(33):4525–4528

McDougal A, Gupta MS, Ramamoorthy K, Sun G, Safe SH (2000) Inhibition of carcinogen-induced rat mammary tumor growth and other estrogen-dependent responses by symmetrical dihalo-substituted analogs of diindolylmethane. Cancer Lett 151(2):169–179

Azizi N, Gholibeghlo E, Manocheri Z (2012) Green procedure for the synthesis of bis (indolyl) methanes in water. Sci Iran 19(3):574–578

Guo RY, An ZM, Mo LP, Yang ST, Liu HX, Wang SX, Zhang ZH (2013) Meglumine promoted one-pot, four-component synthesis of pyranopyrazole derivatives. Tetrahedron 69(47):9931–9938

Aboonajmi J, Maghsoodlou MT, Hazeri N, Lashkari M, Kangani M (2015) Tartaric acid: a natural, green and highly efficient catalyst for the one-pot synthesis of functionalized piperidines. Res Chem Intermed 41(11):8057–8065

Bagul SD, Rajput JD, Bendre RS (2017) Synthesis of 3-carboxycoumarins at room temperature in water extract of banana peels. Environ Chem Lett 15(4):725–731

Patil MM, Bagul SD, Rajput JD, Bendre RS (2018) Clean synthesis of coumarin-3-carboxylic acids using water extract of rice straw husk. Green Mater 6(4):143–148

Dubois M, Gilles KA, Hamilton JK, Rebers PT, Smith F (1956) Colorimetric method for determination of sugars and related substances. Anal Chem 28(3):350–356

Nielsen SS (1998) Food analysis, vol 86. Aspen Publishers, Gaithersburg

Robinson HW, Hogden CG (1940) The biuret reaction in the determination of serum proteins. 1. A study of the conditions necessary for the production of a stable color which bears a quantitative relationship to the protein concentration. J Biol Chem 135:707–725

Bandgar BP, Shaikh KA (2003) Molecular iodine-catalyzed efficient and highly rapid synthesis of bis (indolyl) methanes under mild conditions. Tetrahedron Lett 44(9):1959–1961

Xie ZB, Sun DZ, Jiang GF, Le ZG (2014) Facile synthesis of bis (indolyl) methanes catalyzed by α-chymotrypsin. Molecules 19(12):19665–19677

Shirini F, Fallah-Shojaei A, Samavi L, Abedini M (2016) A clean synthesis of bis (indolyl) methane and biscoumarin derivatives using P 4 VPy–CuO nanoparticles as a new, efficient and heterogeneous polymeric catalyst. RSC Adv 6(54):48469–48478

Rajput JD, Bagul SD, Tadavi SK, Karandikar PS, Bendre RS (2016) Design, synthesis and biological evaluation of novel class diindolyl methanes (DIMs) derived from naturally occurring phenolic monoterpenoids. Med Chem 6:123–128

Acknowledgements

VP & BM is greatly acknowledged SERB-DST for young scientist fellowship and University Grant Commission (UGC) New Delhi for UGC Faculty Recharge Programme (FRP).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There are no conflicts to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Rajput, J., Koli, S., Mohite, B. et al. A green tactic for the synthesis of classical 3,3-bisindolylmethanes in waste curd water. SN Appl. Sci. 1, 1187 (2019). https://doi.org/10.1007/s42452-019-1212-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-019-1212-y