Abstract

Gears are used to transmit mechanical power in systems such as automotives, automation and machine tools. The demand for lighter and optimally designed gears is high in power transmission systems, as they save material, energy and also considerably influence performance. Hence, in this paper, a bevel gear pair is optimized. The problem consists of a non linear objective function, four design variables and eight inequality constraints. The objective is to minimize the volume of the gear. The design variables are: number of teeth, module, face width and diameter of the shaft, which is a new addition. Apart from considering regular mechanical constraints, six other additional critical constraints on contact ratio, load carrying capacity, power loss, root not cut, no involute interference and line of action are also included. Nature inspired algorithms, namely, simulated annealing, fire fly, cuckoo search and fmincon solver are employed in MATLAB environment. Results of simulation are analysed, compared and validated with literature.

Similar content being viewed by others

1 Introduction

Bevel gears are used to change the direction of rotation of a shaft. They are usually mounted on shafts that are 90° apart. Three types of teeth can be identified on bevel gears viz. teeth straight, spiral or hypoid. Straight bevel gears have straight cut teeth, and a taper as shown in Fig. 1. They find their application in transmission systems, where low speed and production cost are required [1]. Bevel gears provide high coincidence and smooth transmission.

Designing a bevel gear pair is a tiresome job, as it involves various factors such as gear geometry, heat treatment and manufacturing, while accounting for practical considerations such as high strength, high accuracy, low noise and low volume. Low volume gears offer a considerable decrease in energy consumption [2]. The stipulations of AGMA are used for standard mechanical constraints.

Here is an account of the various researches done by the researcher. Yokota et al. [3] deployed an improved GA to optimize the weight of the gear pair. They accounted gear bending strength and torsional strength of the shaft. Marjanovic et al. [4] established a realistic approach to optimize spur gears trains. Golabi et al. [5] applied a non-linear programming to find parameters for optimum design of gear box. They employed a two-phase evolutionary algorithm to optimize the design of a two-stage helical gear reducer [5]. Mendi et al. [6] got optimum volume of gearbox by using genetic algorithm (GA). The volume reduction was 1.47% as compared to that of analytical method. Thompson et al. [7] minimized volume of two and four stage gears taking into account surface fatigue life and executed trade off analysis. Gologlu and Zeyveli [8] demonstrated the capability of GA, for obtaining minimum volume of two stage helical gearbox. Zhang et al. [9] conducted design optimization on a bevel gear, through a software based on GA. Tudose et al. [10] optimized two stage coaxial helical gearbox by using GA. Tamboli et al. [11] minimized volume of a helical gear pair. They obtained energy efficient helical gear pair using particle swarm optimization (PSO). Panda et al. [12] applied differential evolution (DE) algorithm for minimizing the weight of spur gear. They also designed a CAD model and analysed stress using ANSYS for low velocity and production cost applications. Marcelin [13] solved a multi-objective optimization problem of a gear pair design. He confirmed that GA was more efficient than conventional algorithms. Yang and Deb [14] presented a study on optimization of the design of springs and welded beam structures. The cuckoo search (CS) technique they used had newer standard and stochastic test functions. It yielded the best solutions than that of an efficient particle swarm optimiser. Kazemzadeh-Parsi [15] presented a modified fire fly (FA), consisting of added memory, newborn fireflies and updated formula. He evaluated the applicability of the proposed method, with three classical engineering design optimization problems and compared results with literature. Zang et al. [16] reviewed that FA and CS algorithms are preferred by various researchers for design optimization problems, as they offer efficient computation and faster convergence. Savsani et al. [17] engaged simulated annealing (SA) and PSO algorithms to minimize weight of spur gears. Patel et al. [18] optimally designed a two stage spur gear train for minimum volume and maximum power transmission. They took into account standard mechanical constraints as well as wear and scuffing as tribological constraints. They proved that the inclusion of tribological constraints increase the efficiency. But it also slightly increases the volume of the gear box. Ang et al. [19] devised a 3-Dimensional parametric modelling method for a straight bevel gear. Zhang et al. [9] developed design optimization software for a bevel gear for minimum volume. It was based on integer serial number encoding GA. He took module, face width and face width factor as design variables subject to normal mechanical constraints. Zolfagari et al. [2] optimized volume of straight bevel gear governed by the AGMA instructions, through SA and GA. Nevertheless, Zolfagari et al. [2], had not considered an important design variable, namely, the shaft diameter and also certain other critical mechanical constraints. To narrow down the gap identified in Zolfagari et al. [2], an additional critical design variable and constraints are introduced in this paper.

The literature on bevel gear volume optimization reveals a gap as follows:

-

1.

Research based on nature inspired algorithms, namely, SA, FA and CS algorithms is very much limited. Most of the optimization problems in engineering are highly nonlinear, dynamic and large. This calls for the application of powerful optimization techniques such as SA, FA and CS that handle variables or constraints, to make a huge difference to the industry [16].

-

2.

The researchers used either conventional or less efficient techniques, that end up in local minimum search, converge slowly, and inefficient and thus fruitless [9]. In many cases, they do not find global optimum and require too many resources to obtain the same. Further GA and PSO techniques are also less efficient, as they converge prematurely. [2].

-

3.

Critical mechanical constraints viz. contact ratio, load carrying capacity, and power losses, root not cut, no involute, line of action are extremely important in optimum bevel gear design. But these constraints were not considered in the literature.

-

4.

Traditional techniques such as gradient-based algorithms reported in the literature are mostly local search methods. They often find it difficult to confront challenging optimization problems [16].

To tide over these, in this paper, besides considering regular constraints, one more design variable and six other mechanical constraints are added. Certain other equivalent constraints in Zolfagari et al. [2] are replaced by a single inequality constraint to make the work simpler. This research is based on Zolfagari et al. [2], but this paper bridges the gap identified in their work, by introducing certain essential additional design variable and constraints.

The novel things added in the present paper are as follows:

-

1.

Shaft diameter—It is added as one more design variable. Also a constraint is imposed on it, taking into account both torque and maximum bending moment on the shaft [18].

-

2.

Contact ratio (CR)—It is the average number of teeth in contact as the gear rotates together. It is absolutely required that the tooth profiles be proportional, in order that a second pair of mating teeth comes into contact, before the first pair loses contact. CR must be between 1.2 and 2 for bevel gear [20]. With greater CR, the operations of the gear become quieter and smoother.

-

3.

Load carrying capacity—It is one of the functional characteristic of the gear [21]. In this work, first, the optimum values for minimum volume are obtained. These values are applied to find out the load carrying capacity. Now the constraint condition is set in such a way that, this value should be more than the minimum allowed load carrying capacity of the gear.

-

4.

Power loss—There are mainly two types of power losses in the gears viz. load dependant and load independent losses. The total power losses due to meshing of gears, loss in bearings and in the seals should be less than 1.2–2.2% of input power. The range of power loss percentage is arrived based on the results available in [18].

-

5.

Root not cut—In this research, prevention of undercutting is countered by considering only one equation. Zolfagari et al. [2] did consider this constraint, but they addressed the problem with six equivalent constraints. But in this research, the task is simplified, by using a single equivalent constraint, in order to provide the designer an acceptable solution in less time.

-

6.

Line of action—In order to experience smooth continuous rotation, the arc of action should be greater than the line of action [1]. Accordingly, the constraints are formulated.

-

7.

Popular nature inspired algorithms are used in this research. They are much simpler and powerful enough to solve any design problems [9, 22,23,24]. They also give faster convergence and greater computational speed. Many research [23, 24] indicate nature inspired algorithms are superior and effective in dealing with optimization problems involving both continuous and discrete variables [9].

The following are the advantages of SA, FA and CS algorithms employed in this paper.

-

(a)

SA shows better robustness and global searching capability [25].

-

(b)

FA is a very capable global optimizer based on swarm intelligence. It is successfully demonstrated in solving various engineering problems. [16] Further, it can give the global and local optima simultaneously and electively. As the firefly does not memorize any history of better situation and move regardless of it, it searches in the global space instead of local search. Thus it is superior over traditional algorithms [26]. Furthermore, FA has a special merit that different fireflies function almost independently. This makes it suitable for parallel implementation as well.

-

(c)

Certain problems which demand large search spaces can be easily addressed by CS algorithm. As CS is a good and efficient combination of DE, PSO, and SA, it has efficient random walks and balanced mixing. Lévy flights of CS are more competent than other random-walk-based randomization techniques. Hence CS is adept in global search and global convergence [16, 23, 27, 28].

-

8.

The equivalent constraints in Zolfagari et al. [2] are replaced by a single inequality constraint, as given in Eq. (8) to make the work simpler in this research. In order to check interference, increase contact ratio and get stronger pinion teeth, the working depth of teeth is taken as 2 m, the bevel pinion is planned with the larger addendum (0.7 working depth) and the gear addendum is taken as 1 [1].

This is how the paper is organised: in Sect. 2, the nature inspired optimization algorithms SA, FA, CS and MATLAB solver fmincon are discussed. In Sect. 3, the formulation of the mathematical model of the bevel gear design problem is presented. In Sect. 4, a design example, simulation and numerical analysis of the design are reported. Finally, the conclusion drawn and scope of the work is presented.

2 Methods of solution

Nature inspired methods viz. SA, FA, CS are employed for solving the problem. These methods are briefly discussed in the following section.

2.1 Nature inspired metaheuristic algorithms

The supremacy of contemporary metaheuristic algorithms is in the imitation of the best characteristics from nature, principally biological systems.

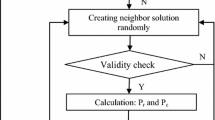

2.1.1 Simulated annealing (SA)

SA is a primitive and an admired algorithm [25]. It is an iterative technique launched by Kirkpatrick in the year 1993. It imitates the annealing process in solids. Its potential is lofty and searching capacity is vast. It does not use any data collected while searching. In this algorithm, firstly, an initial answer is obtained at an elevated temperature, wherein adjustment can be accommodated with greater possibility. Upon running the algorithm further, and as the temperature goes down slowly, the accommodation of favourable moves increases. It also has the power to give global optimality, as it can differentiate between diverse local optima.

The parameters of SA applied in this research are:

Initial temperature, T_init = 1.0; Final stopping temperature, T_min = 1e−10; Min value of the function, F_min = −1e + 100; Maximum number of rejections, max_rej = 500; Maximum number of runs, max_run = 150; Maximum number of accept, max_accept = 50; Initial search period, initial_search = 500; Boltzmann constant k = 1; Energy norm (e.g., Enorm = 1e−8) Enorm = 1e−5;

2.1.2 Firefly algorithm (FA)

FA was introduced by Xin-She Yang at Cambridge University in 2007 [26, 29]. It is one of the powerful techniques. It imitates the blinking manner of firefly insects. This manner of fireflies is an attempt to attract the opposite sex. Mathematically, it is assumed that all fire flies are unisex. Also no firefly is exempted in attraction. The level of attractiveness is directly relative to its brightness. Given a group of binary combination of fireflies, a dim firefly is more attracted to the flashing one. In the absence of brighter one, it moves randomly. In FA algorithm, it is possible to adjust the values γ and α to outperform conventional algorithms and PSO. Fireflies have the unique feature of combining more closely around each optimum.

For implementation of FA, in this work, the parameters used are: No. of fireflies = 20, number of iterations = 250, α = 0.5, γ = 1 and \(\upbeta_{\text{o}}\) = 0.2. These have been preferred after cautious adjustment to suit for solving bevel gear optimization.

2.1.3 Cuckoo search algorithm (CS)

It is a potent nature-inspired algorithm, launched by Yang and Deb [14, 23, 24]. It is purely inspired by the manner of cuckoos looking for nests where they could lay eggs. It has three rules as follows: (1) Each cuckoo can lay an egg in an arbitrarily chosen nest. (2) The feasible nests carry over to the next generation of cuckoos. (3) The number of existing host nests is limited, and the egg laid by a cuckoo is discovered by the host bird with a probability, pa between 0 and 1. Each egg in a nest stands for a solution and a cuckoo egg a fresh solution. The plan is to use the recent and best solutions that are the cuckoos to substitute an average solution in the nests.

The parameters used in CS are: n = 25 nests, α = 1 and pa = 0.25 for implementation. From the simulations, it is found that the considered parameters are good for the optimization problem.

2.2 MATLAB solvers

MATLAB optimization solvers try to find a local minimum of the objective function in the vicinity of a starting point. These solvers can be used for obtaining optimum solutions for unconstrained, linear programming, quadratic programming, and nonlinear programming problems.

2.2.1 Fmincon

It is a function built in optimization Toolbox of MATLAB, which seeks the minimum of a scalar function of multiple variables, within a region specified by linear constraints and bounds [30]. It is one of the most flexible Nonlinear Programming solvers. It is based on sequential quadratic programming. It finds a constrained minimum of a scalar function of several variables starting from an initial estimate.

3 Formulation of optimization model for bevel gear pair

3.1 Objective function

It is the volume of bevel gear equation adopted by Zolfagari et al. [2]:

where r is the cone pitch radius (mm), and \(\delta _{1} /\delta _{2}\) is the cone angle of pinion/gear (radians).

3.2 Design variables

Four parameters of the bevel gear pair are selected as design variables, namely, number of teeth z, module of the gears m, face width b and diameter of the shaft ds. The design parameters vector is given by:

3.3 Constraints

3.3.1 Condition of contact and bending stress

The upper limits of both contact stress and bending stress should not exceed the permissible values as per AGMA instructions. Also the linear velocity on the outer diameter should be within acceptable values of AGMA standards as follows [2]:

where \(K_{A} ,K_{V} ,K_{H\beta } ,K_{\theta }\) are overload, dynamic, load distribution and temperature factors, and ZJ, ZI, YZ, \(Y_{\beta }\) are the bending, contact geometry factors, size factor for bending and lengthwise curvature factor for bending strength, and \(\sigma_{Hlim} ,\sigma_{Flim}\) are the allowable contact and bending stress numbers (N/mm2).\(Z_{X} ,Z_{C} ,Z_{NT} ,Z_{Z} ,Z_{W}\) and ZE are the size factor, crowning stress cycle factor, reliability factor and hardness factor for pitting resistance and elastic coefficient for pitting resistance (N/mm2)0.5, and Wt is the transmitted load (N). SH and SF are contact safety and bending safety factors.

where Am, met are the mean cone distance (mm) and outer transverse module (mm).

3.3.2 Condition of minimum number of teeth on pinion

The condition for minimum number of teeth on pinion is given by [31],

3.3.3 Condition of not root cut in small bevel gear

The condition of rot not cut for a small bevel gear is given by [9],

3.3.4 Condition of maximum peripheral speed

For straight bevel gear, the peripheral speed of the average diameter vm should satisfy the constraint as follows [9]:

3.3.5 Condition of modulus

For efficient power transmission, the minimum modulus is not less than 1.5, given by,

3.3.6 Condition of shaft diameter

The constraint from [18] is applied as the action of bevel gears is same as that of equivalent spur gears [32].

where Sy is the yield strength of the shaft material (N/mm2), T, torque transmitted by the shaft (N mm) and maximum bending moment M, on the shaft (N mm).

3.3.7 Power loss

The power loss equation in [18] is used in this work, as the action of bevel gear is same as that of equivalent spur gears [18]. The range of power loss percentage is arrived from the results for various power inputs presented in [18]. It must be limited to 1.2–2.2% of input power.

F is the bearing load (N), v is the peripheral speed (m/s).

3.4 Design example and numerical results

A bevel gear pair is considered. The specifications, coefficients used in strength formulas and input values used for the same are given in Table 1 [2]. The design parameters and working conditions are presented in Table 2. All the parameters are considered as continuous.

The results given by the nature inspired algorithms SA, FA, CS and MATLAB solver fmincon are presented in Table 3. Also a comparison between the optimal design parameters values given by the best algorithm (CS) of this work and literature [2] is presented in Table 4 and Fig. 5.

From Table 3, it is observed that optimal values given by SA, FA, CS and MATLAB solver and fmincon for z, m, b (17, 1.5, 23 mm) are almost the same. However, for ds different optimal values are given by SA, FA (17 mm, and 24 mm). The CS and MATLAB solver fmincon give the same values (15 mm and 15 mm). The lowest value (64.071 dm3, 64.071 dm3) is by CS and fmincon. As for module of the bevel gear, SA, FA, CS and fmincon, give the same value (1.5 mm). Same values of number of teeth values are given by SA, FA, CS and MATLAB solver (17 teeth). The highest value of time is taken by CS (46.8 s) and the lowest time by SA (0.878 s). Figure 2 shows the graphical representation of the results obtained by various algorithms and solvers.

In this research, CS technique and MATLAB fmincon solver give the best volume (64.071 dm3, 64.071 dm3). Fascinatingly, the minimum volume of the bevel gear drive by both CS and fmincon are same. Being a non conventional method, CS algorithm is more desirable for solving the problem. Results show that all the algorithms of this work are faster and computationally efficient.

From Fig. 3, it is observed that at zeroth iteration, the function value is 7 × 108 mm3 and it decreases up to 4.2 × 108 mm3 in first iteration after that it keeps on decreasing to 1.8 × 108 mm3 up to the twentieth iteration and decreases further up to twenty-fifth iteration then and remains constant at 6.407 × 107 mm3 for the next iterations. Optimal values of design variables and all objective functions given by fmincon are tabulated in Table 3. As CS gives the best results, it is decided to compare the optimum values of design parameters with literature [2]. Table 4 gives the percentage change in optimum parameter values between CS and literature.

Figure 4 shows the optimized values of design variables by fmincon. These graphs plot the vector entries of the individual with the best fitness value in each generation. Figure 3 shows the function value versus iteration and fitness value versus generations given by fmincon.

Table 4 shows there is 8.2% reduction in volume of bevel gear drive, as compared to literature. At this point, it is important to mention that this reduction in volume of bevel gear drive is achieved after considering additional critical mechanical constraints. Also the optimal values by various algorithms of this research for different power inputs are obtained and presented in Table 5. Figure 5 shows the graphical representation of the percentage change in optimal parameter values obtained by the CS algorithm and literature. Considerable percentage change in optimal design parameters values is also noted. It is observed that an increase in value of 19.4% in b, and a decrease of 56.6% in m of the drive. There is a significant reduction in volume by 8.2%.

Comparison of results of CS of this work and results presented in [2]

Accordingly the graphical representation for various power input 5 kW, 7.5 kW, 10 kW and 15 kW are made in Fig. 6.

Further, a significant percentage of volume reduction is achieved for other power inputs (7.5 kW, 10 kW and 15 kW) as compared to literature and the reduction is proportionate. It is noteworthy to state that this reduction in volume is achieved after including additional critical mechanical constraints.

4 Conclusion

In this paper, optimal volume design for a bevel gear pair using nature inspired algorithms, namely, SA, FA and CS and MATLAB solver fmincon has been obtained. The design variables are: number of teeth, module, face width and the diameter of the shaft, which is newly added. Apart from considering regular mechanical constraints, six other additional critical constraints on contact ratio, load carrying capacity, power loss, root not cut, no involute interference and line of action are also considered. The following things are observed:

-

1.

For computing optimum volume, CS algorithm gives the best result as follows: z = 17.097; m = 1.52 mm, b = 23.870 mm; ds = 15.00 mm and V = 64.071 dm3 for 5 kW power. All constraints are well satisfied. The capability of the novel method is evaluated by comparing the results with literature.

-

2.

The new approach combined with nature inspired algorithms is able to significantly reduce the volume by 7.3% (SA) and 7.7% (FA) and 8.2% (CS) for 5 kW input power. This trend continues for other power inputs as well. A significant percentage of volume reduction is achieved for other power inputs (7.5 kW, 10 kW and 15 kW) also as compared to literature. It is worthwhile to mention that this much reduction in volume is achieved after including additional critical mechanical constraints.

-

3.

The employed nature inspired algorithms SA, FA and CS are faster and computationally more efficient. Further, this research can be used as reference for other related mechanical elements optimal designs.

References

Gopinath K, Mayuram MM (2009) Lecture notes on bevel gear, Machine design II. Indian institute of technology, Madras, pp 1–17

Zolfaghari A, Goharimanesh M, Akbari AA (2017) Optimum design of straight bevel gears pair using evolutionary algorithms. J Braz Soc Mech Sci Eng 39:2121–2129

Yokota T, Taguchi T, Gen M (1998) A solution method for optimal weight design problem of the gear using genetic algorithms. Comput Ind Eng 35:523–526. https://doi.org/10.1016/S0360-8352(98)00149-1

Marjanovic N, Isailovic B, Marjanovic V, Milojevic Z, Blagojevic M, Bojic M (2012) A practical approach to the optimization of gear trains with spur gears. Mech Mach Theory 53:1–16. https://doi.org/10.1016/j.mechmachtheory.2012.02.004

Golabi S, Fesharaki JJ, Yazdipoor M (2014) Gear train optimization based on minimum volume/weight design. Mech Mach Theory 73:197–217

Mendi F, Baskal T, Boran K, Boran FE (2010) Optimization of module, shaft diameter and rolling bearing for spur gear through genetic algorithm. Expert Syst Appl 37:8058–8064. https://doi.org/10.1016/j.eswa.2010.05.08214

Thompson DF, Gupta S, Shukla A (2000) Tradeoff analysis in minimum volume design of multi-stage spur gear reduction units. Mech Mach Theory 35:609–627. https://doi.org/10.1016/S0094-114X(99)000361

Gologlu C, Zeyveli M (2009) A genetic approach to automate preliminary design of gear drives. Comput Ind Eng 57:1043–1051

Zhang X, Rong Y, Yu J, Zhang L, Cui L (2011) Development of optimization design software for bevel gear based on integer serial number encoding genetic algorithm. JSW 6:915–922. https://doi.org/10.4304/jsw.6.5.915-92220

Tudose L, Buiga O, Stefanache C (2010) Automated optimal design of a two-stage helical gear reducer. Struct Multidiscip Optim 42:429–435

Tamboli K, Patel SP, George M, Sanghvi R (2014) Optimal design of a heavy duty helical gear pair using particle swarm optimization technique. Procedia Technol 14:513–519

Panda S, Biswal BB, Jena SD, Mishra D (2017) An approach to weight optimization of a spur gear. Proc Inst Mech Eng Part J J Eng Tribol 231:189–202

Marcelin JL (2001) Genetic optimization of gears. Int J Adv Manuf Technol 19:910–915. https://doi.org/10.1007/s001700170101

Yang XS, Deb S (2010) Engineering optimization by cuckoo search. Int J Math Model Numer Optim 1:330–343

Kazemzadeh-Parsi MJ (2014) A modified firefly algorithm for engineering design optimization problems. Iran J Sci Technol Trans Mech Eng 38:403–421

Zang H, Zhang S, Hapeshi K (2010) A review of nature-inspired algorithms. J Bionic Eng 7:S232–S237

Savsani V, Rao RV, Vakharia DP (2011) Optimal weight design of a gear train using particle swarm optimization and simulated annealing algorithms. Mech Mach Theory 45:531–541. https://doi.org/10.1016/j.mechmachtheory.2009.10.010

Patil M, Ramkumar P, Krishnapillai S (2017) Multi-objective optimization of two stage gear box using NSGA II. SAE technical paper 2017-28-12

Ang X, Ding J (2007) 3-Dimensional parametrical modelling method of straight bevel gear. Eng Graph Trans 6:22–25

Radzevich SP (2012) Dudley’s handbook of practical gear design and manufacture, 2nd edn. CRC Press, Boca Raton

Bhandari VB (2010) Design of machine elements. Tata McGraw-Hill, New Delhi

Yang X (2008) Introduction to mathematical optimization—from linear programming to mataheuristics. Cambridge International Science Publishing, Cambridge

Yang XS (2008) Nature-inspired metaheuristic algorithms. Luniver Press, Bristol

Talbi EG (2009) Metaheuristics: from design to implementation. Wiley, New York

Kirkpatrick S, Gelatt CD, Vecchi MP (1983) Optimization by simulated annealing. Science 220(4598):671–680

Yang XS (2009) Firefly algorithms for multimodal optimization. In: Watanabe O, Zeugmann T (eds) Stochastic algorithms: foundations and applications, SAGA 2009. Lecture notes in computer science, vol 5792. Springer, Berlin, pp 169–178

Solihin MI, Zanil MF (2016) Performance comparison of cuckoo search and differential evolution algorithm for constrained optimization. In: International engineering research and innovation symposium (IRIS), vol 160, no 1, pp 1–7

Adnan MA, Razzaque MA (2013) A comparative study of particle swarm optimization and cuckoo search techniques through problem—specific distance function. In: International conference on information and communication technology (ICoICT), Bandung, Indonesia

Yang XS (2010) Firefly algorithm, Levy flights and global optimization. In: Bramer M et al (eds) Research and development in intelligent systems XXVI. Springer, London, pp 209–218

Arora JS (2012) Introduction to optimum design, 3rd edn. Academic Press, New York

Maitra G (2003) Handbook of gear design, 2nd edn. Tata MacGraw-Hill, New Delhi

ANSI/AGMA 2003-B97 (2003) Design manual for bevel gears. American Gear Manufacturers Association (AGMA), Alexandria, pp 1–32

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ebenezer, N.G.R., Ramabalan, S. & Navaneethasanthakumar, S. Advanced design optimization on straight bevel gears pair based on nature inspired algorithms. SN Appl. Sci. 1, 1155 (2019). https://doi.org/10.1007/s42452-019-1171-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-019-1171-3