Abstract

Rayon-based activated carbon fiber (ACF) was modified with several methods: acetonitrile thermal chemical vapor deposition at 800 °C (8AN) to dope nitrogen element on carbon surface, heat treatment at 950 °C (9.5HT) to convert doped nitrogen species into quaternary nitrogen (N-Q) and steam activation at 800 °C (8ST) to additionally develop pore structure. The modified samples were evaluated as adsorbents for the removal of nitrate from NaNO3 aqueous solution at equilibrium solution pH (pHe) around 3.0. Sequential modification of ACF with 8AN, 9.5HT and 8ST achieved the greatest adsorption capacity at 0.7 mmol/g in all prepared samples. The modified adsorbent was probably included in the greatest group in nitrogen-doped carbonaceous adsorbents for nitrate removal. To inspect the high adsorption capacity, specific surface area, elemental analysis and X-ray photoelectron spectroscopy measurements were conducted comparing with the other prepared adsorbents. Based on the data analysis, some specific surface area and N-Q might play an important role in the adsorptive removal of nitrate.

Similar content being viewed by others

1 Introduction

Phosphorous and nitrate/nitrite as well as ammonia have been playing a decisive role as fertilizers in increasing wheat production [1]. However, nowadays, excess fertilizing application leads to eutrophication of lakes and pond, red tide in costal sea area and nitrate contamination of groundwater that are frequently found worldwide. Once a large amount of ammonia was produced in industrial scale, it will be released into environment and easily oxidized to nitrate/nitrite resulting in environmental loading in lake, groundwater and costal sea area [2]. At first, the nitrate/nitrite problems were found in developed countries, but the contamination was also expanded to developing countries even more severely [3]. Particularly, removal of nitrate from drinking water is one of the most important technologies to be established. US-EPA together with other organizations demonstrated that adsorptive removal is one of the most feasible treatments for the safe drinking water supply [4,5,6]. Sometimes, activated carbon (AC) and ion-exchanger cartridge is set at the faucet as a water-purifying device in home kitchen. AC is principally used for removal of organic pollutants, while ion exchanger is supplied for ionic contaminants like Pb(II), Cd(II) and nitrate/nitrite.

In general, carbonaceous materials have robustness against heating and acid/basic conditions, thereby carbons are expected to be easily regenerated with some treatments compared to polymer substances. In our previous study, oxidized activated carbons (ACs) and activated carbon fibers (ACFs) were successfully prepared to reduce the concentration of cationic contaminants as Pb(II), Cd(II), Ni(II) and other heavy metal ions in aqueous phase [7, 8]. However, development of carbonaceous adsorbents to uptake anionic pollutants as As(III), Cr(VI), phosphate, nitrate, etc., are still a challenging study, because adsorption capacities are far below compared to ion-exchange resin [9, 10]. In our preliminary study, nitrogen doping was repeatedly carried out using various procedures to increase the adsorption capacities of anions. At first, oxidized ACs were treated with ammonia to efficiently enhance the adsorption capacity of nitrate [10]. Next melamine form was used as a starting material for carbonization and methylation of nitrogen elements using methyl iodide for pyridinic (N-6) and pyrrolic (N-5) type nitrogen to yield quaternary nitrogen (N-Q) on carbonized melamine for the nitrate removal [11]. Air-stabilized polyacrylonitrile (PAN) fiber was also supplied for the preparation of nitrate adsorbent, and 0.6 mmol/g of nitrate density could be achieved by steam activation at 800 °C and heat treatment at 950 °C in an electric furnace [12]. Recently, we have also investigated thermal chemical vapor deposition (CVD) to dope nitrogen into a rayon-based activated carbon fiber (ACF), namely KF1500, and large capacities of 0.6–0.7 mmol/g of nitrate adsorption by the carbonaceous adsorbent could be successfully attained as well [13, 14]. In the present study, some physical and chemical properties on carbon surface were examined to interpret the large adsorption capacities of nitrogen-doped ACFs.

2 Experimental

2.1 Preparation of adsorbent and adsorption experiments

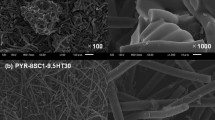

Rayon (cellulose)-based activated carbon fiber KF1500LDA (hereafter denoted as KF) was purchased from Toyobo Co. Ltd., Japan. Although a part of procedures for the modification of KF had already been briefly described in the previous proceedings [13], detailed methods could be described as follows. Ca. 2 g of felt-shaped KF was placed in quartz tube of 25 ϕ inner diameter and inserted into a horizontal cylinder-shaped electric furnace. Thermal chemical vapor deposition (CVD) was made by slowly sending acetonitrile solution to 100 mL/min helium flow in the quartz tube using tube pump and heated up to 800 °C at KF sample for doping nitrogen element onto graphene sheets. KF modified with the acetonitrile CVD is referred to as KF-8ANx in which x is volume of acetonitrile sent to the KF. For example, KF-8AN20 represents that KF was treated with 20 mL acetonitrile at 800 °C. Heat treatment of KF sample was conducted at 950 °C under 100 mL/min helium flow as well. When resultant sample is denoted as KF-9.5HT30, it means KF sample has been heat-treated at 950 °C for 30 min. Likewise, steam activation was performed to develop the pore structure by injecting pure water drop by drop into the helium flow and completely heating up to 800 °C to become super heat steam. KF-8ST30 indicates that KF has been activated by the 800 °C super heat steam generated from 30 mL pure water in total. KF was modified using some combinations of above methods; for instance, KF-8AN20-9.5HT30-8ST30 represents sequential treatments of 20 mL acetonitrile thermal CVD at 800 °C, heat treatment at 950 °C for 30 min in helium flow and finally steam activation at 800 °C injecting 30 mL water. An n-heptane (C7) instead of acetonitrile (AN) was also loaded onto KF by thermal CVD to compare with AN thermal CVD.

Thirty milligrams of the modified sample and 15 mL of sodium nitrate (NaNO3) solution were mixed and agitated for at least 12 h, because 6 h was confirmed to be sufficient to achieve the equilibrium state of NO3− adsorption in our preliminary kinetic study. The initial NaNO3 concentration was 3.23 mmol/L (200 mg-NO3−/L). The equilibrium solution pH (pHe) was adjusted to about 3 by use of 0.1 M HCl solution, because maximum adsorption amounts of nitrate could be always observed at pHe 3, in which differences in adsorption capacities were easily distinguished among adsorbents [10,11,12]. The solution pH was measured with portable pH meter, HORIA model D-51. Concentration of NO3− in the equilibrium solution was determined by IC (ion chromatograph), Nippon Dionex KK, model ICS-1100. The adsorption amount on the adsorbent at equilibrium state Qe in mmol/g was calculated with Eq. (1):

where C0 and Ce are initial and equilibrium NO3− concentration in mmol/L, respectively, and v and w are 15 mL solution volume and 30 mg adsorbent weight. Bead-shaped granular activated carbon (BAC) was obtained from Kureha Co., Ltd., and used as a reference material for adsorption.

2.2 Characterization of the carbonaceous adsorbents

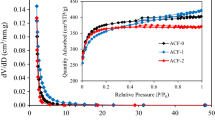

To inspect the relationship between adsorption amounts of nitrate and modification procedures of KF ACF, surface and bulk characterizations were carried out. Specific surface area and pore distributions were calculated from N2 adsorption and desorption isotherms at − 196 °C using BELSORP-mini II surface analyzer (MicrotracBEL Corp., Japan). The specific surface area was measured by BET theory (SBET) and SPE method using αs plots (\( S_{{\alpha_{\text{s}} }} \)) [15]. Total pore volume (Vtotal) was determined from N2 volume adsorbed at relative pressure (p/p0) at 0.995. Micropore volume (Vmicro) was estimated from the αs plots with SPE methods, and then mesopore volume (Vmeso) could be obtained by just subtracting Vmicro from Vtotal. CHN bulk elemental analysis was performed by PerkinElmer PE2400 CHN analyzer. Oxygen content was calculated by balance on the assumption that all other elements except C, H and N would be O (oxygen). X-ray photoelectron spectroscopy (XPS) analysis was conducted with XPS, PHI1800, ULVAC PHI, using Al-Kα line to obtain N(1s) spectra and separated them into pyridine type (N-6), pyrrole (N-5), quaternary (N-Q) and pyridine-N-oxide (N-X) signals by post-deconvolution analysis [16].

3 Results and discussion

Figure 1 shows NO3− adsorption amounts in mmol/g at the equilibrium state for 10 different carbonaceous adsorbents, pristine BAC, KF and KF treated with acetonitrile, heat treatment, super heat steam and their combinations, together with their equilibrium solution pH (pHe). The 10 samples were selected out of more than 300 KF modified samples, in which both trial-and-error experiments were included, and in our experimental system, the coefficient of variation (Cv) could be controlled to be < 5% in reproducibility for the preparation of adsorbents followed by adsorption experiments of nitrate. Table 1 displays comparison of nitrate adsorption capacities of ACs and ACFs obtained in our previous and present works with those reported by other researchers in recent years. Presently, the prepared KF ACF in this study seems to be one of the excellent adsorbents for nitrate among ACs and ACFs.

Adsorption amounts of nitrate onto bead-shaped granular activated carbon (BAC) and KF1500 activated carbon fibers (ACFs) modified with thermal chemical vapor deposition (CVD) at 800 °C using 20 mL acetonitrile (8AN20), heat treatment at 950 °C for 30 min (9.5AN30), steam activation at 800 °C using 30 mL water (8ST30) and their combination such as 8AN20-9.5HT30-8ST30 together with corresponding equilibrium solution pH (pHe). The initial nitrate concentration is 200 mg-NO3-/L (3.23 mmol/L). Adsorption conditions: amount of adsorbent of 30 mg and solution volume of 15 mL at r.t. at 100 rpm for 12 h or more

The results of textural and surface properties and elemental analysis of the prepared samples are summarized in Table 2. In the original KF (KF1500), although KF was mainly originated from nitrogen-free rayon (cellulose)-based ACF, a small amount of nitrogen (1.7%) could be detected. This is caused by a partly mixing nitrogen-containing flame retardant in the industrial production process of KF (KF1500). The quantitative deconvolution of XPS spectra of nitrogen doped on six selected KF series is given in Table 3 assuming that N content (%) in Table 2 would be equal to total surface nitrogen, together with the original N(1 s) XPS spectra as partly displayed in Fig. 2.

As can be clearly shown in Fig. 1, adsorption amounts of nitrate were varied from 0.25 to 0.71 mmol/g. Although the adsorption amounts are not simply proportional either to specific surface area (Table 1) or to surface nitrogen content including quaternary nitrogen (N-Q, Table 3), both specific surface area and nitrogen seem to play an important role in the adsorption of nitrate anion. Based on our previous study, surface acidic oxygen function such as carboxy groups (–COOH) strongly inhibits the adsorption of nitrate anion [17]. But in this study, such strong acidic groups were not present, because all adsorbents had been experienced heating atmospheres above 800 °C in which carboxy groups were completely removed as CO/CO2 by decomposition and/or converted to neutral carbonyl groups on the carbon surface [21]. In contrast to carboxy groups, aliphatic amine such as benzyl and phenethyl groups can accept protons (H+) to be positively charged and becomes preferable adsorption sites of nitrate [22]. In this case, the aliphatic amine will also be decomposed by heating below 800 °C.

To the best of our knowledge based on our experience for 15 years of experiments and the literature survey, two major adsorption sites of (a) π-electrons on graphene sheet without electron-withdrawing groups such as acidic functions [17] and (b) quaternary nitrogen (N-Q) can be principally operative as adsorption sites on carbonaceous adsorbents [11]. Since π-electron-rich graphene sheet exhibits weakly negative-charged surface, the graphene can accommodate protons (H+), and then the surface can attract nitrate anion as well. Quaternary nitrogen (N-Q) is always positively charged on the graphene surface independent of solution pH and then it is an ideal sites to adsorb nitrate anion, whereas pyridinic nitrogen (N-6, pKa ranging 5–6) and pyrrolic nitrogen (N-5) may attract nitrate only in acidic region accommodating protons (H+) [23]. In contrast, repulsive force may be operative between these N-6 and N-5 species and nitrate in neutral and basic region, because nitrogen elements of N-6 and N-5 have slightly negative charge due to the lone-pair electrons of nitrogen releasing protons (H+). From the viewpoints of the π-electron-rich graphene sheet and the quaternary nitrogen (N-Q), adsorption amounts of nitrate on BAC, KF, KF-9.5HT30 and KF-8ST30 can be interpreted in terms of specific surface area rather than quaternary nitrogen (N-Q), whereas a small amount of N-Q seems to be detected on the surface of KF and KF-9.5HT30 as shown in Table 3 and Fig. 2. For nitrate adsorption amounts, KF is better than BAC due to the increase in specific surface area and amount of N-Q, whereas in spite of an opposite correlation with specific surface area, KF-9.5TH30 is greater than KF, possibly caused by the decrease in adsorption inhibitors of N-5 and N-6 for KF-9.5HT30. For the KF series treated with acetonitrile thermal CVD, N-Q as well as π-electron-rich graphene sheet seems to play a decisive role for the adsorption of nitrate anion. A 30 mL of acetonitrile thermal CVD for 2 grams of KF almost completely plugged pore structure of KF. Even though more than 99% specific surface area was lost for KF-8AN30, surprisingly adsorption amount of nitrate still remained 74% of KF. This could be caused by the largest amount of N-Q (1.95%) that should compensate the drastic loss of BET specific surface area from 1540 down to 10 m2/g. Fortunately, steam activation of KF-8AN30 with 30 mL pure water again led to the great recovery of the specific surface area from 10 up to 1190 m2/g, whereas nitrogen content and N-Q species moderately decreased from 4.2 to 2.5% and from 1.95 to 1.04%, respectively. Probably by increasing specific surface area accompanied by increasing the extent of exposure of N-Q inside the pore structure, adsorption amount of nitrate anion was raised from 0.28 to 0.61 mmol/g for KF-8AN20-8ST30, even greater than 0.38 mmol/g of the original KF. The further annealing at 950 °C of KF-8AN20-8ST30 resulted in slight decrease in adsorption amount of nitrate anion, despite slight increase in specific surface area and constant values of nitrogen content and N-Q percentage. We are not sure, but due to decrease in oxygen content from 14.1 to 8.8% (declined by 40%), the additional 9.5HT30 annealing, KF-8AN20-8ST30-9.5HT30, may enhance loss of some specific oxygen function as lactone group which can be slightly positively charged and become preferable adsorption site for nitrate. A different sequential modified order of KF-8AN20-9.5HT30-8ST30 showed the greatest adsorption amount of nitrate anion (0.71 mmol/g). After acetonitrile thermal CVD, 9.5HT treatment could efficiently convert doped nitrogen into N-Q inside the plugged structure, and the subsequent steam activation would develop pore structure as large as 1560 m2/g keeping preferable nitrogen, principally N-Q, and oxygen species on KF structure. Since BET surface area of KF-8AN20-9.5HT30-8ST30 is as great as the original KF despite the enhancement of adsorption capacity of nitrate, surface chemistry should be significantly altered to enhance the adsorption capacity of nitrate, especially due to the increase in positively charged N-Q. On the assumption that only the increase in N-Q should contribute to the enhancement of nitrate adsorption, since N-Q was increased by 0.69% (Δ0.49 mmol/g) from 0.35% (0.25 mmol/g) in KF to 1.04% (0.74 mmol/g) in KF-8AN20-9.5HT30-8ST30, and the adsorption amount of nitrate was increased by Δ0.33 mmol/g from 0.38 mmol/g for KF to 0.71 mmol/g for KF-8AN20-9.5HT30-8ST30, about 70% (Δ0.33 mmol/g divided by Δ0.49 mmol/g) of newly introduced N-Q could become adsorption sites for nitrate from a mathematical point of view. For the second best treatment of KF-9.5HT30-8AN20-9.5HT30-8ST30, specific surface area was also the second largest among the 10 adsorbents, but nitrogen could not be effectively doped into KF; total nitrogen content was 1.8%, close to the original KF (1.7%). Doping of carbon using n-heptane instead of acetonitrile, KF-8(C7)15-9.5HT-8ST30, as a reference material, in which both nitrogen and oxygen were decreased compared to the original KF, exhibited the largest nitrate adsorption amount among the adsorbents without additional nitrogen doping, but less than any activated nitrogen-doped adsorbent using the acetonitrile CVD.

4 Conclusions

Rayon (cellulose)-based KF1500 activated carbon fiber (ACF) was modified with acetonitrile thermal CVD at 800 °C combined with steam activation at 800 °C and/or annealing at 950 °C to prepare adsorbents for removal of nitrate (NO3−) from aqueous phase. Sequential treatment of KF1500 with acetonitrile thermal CVD, annealing at 950 °C and then steam activation (KF-8AN20-9.5HT30-8ST30) exhibited the greatest adsorption capacities of 0.71 mmol/g, nearly 2 times greater than the original ACF. Since there is no major difference between KF and KF-8AN20-9.5HT30-8ST30 in specific surface area, the increase in quaternary nitrogen (N-Q) from 0.35 to 1.04% by the thermal CVD and the annealing could play a decisive role in the enhancement of nitrate adsorption. Consequently, nitrogen doping, particularly quaternary nitrogen (N-Q), onto carbon surface could be supposed to be one of the most effective strategies for increasing adsorption capacity of anionic pollutants in aquatic phase.

References

Galloway JN, Townsend AR, Erisman JW, Bekunda M, Cai Z, Freney JR, Martinelli LA, Seitzinger SP, Sutton MA (2008) Transformation of the nitrogen cycle: recent trends, questions, and potential solutions. Science 320(16):889–892. https://doi.org/10.1126/science.1136674

Ying H, Ye Y, Cui Z, Chen X (2017) Managing nitrogen for sustainable wheat production. J Clean Prod 162:1308–1316. https://doi.org/10.1016/j.jclepro.2017.05.196

Erisman JW, Bleeker A, Galloway J, Sutton MS (2007) Reduced nitrogen in ecology and the environment. Environ Pollut 150:140–149. https://doi.org/10.1016/j.envpol.2007.06.033

Clark RM (1987) Evaluating the cost and performance of field-scale granular activated carbon systems. Environ Sci Technol 21:573–580. https://doi.org/10.1021/es00160a008

Magnuson ML, Speth TF (2005) Quantitative structure-property relationships for enhancing predictions of synthetic organic chemical removal from drinking water by granular activated carbon. Environ Sci Technol 39:7706–7711. https://doi.org/10.1021/es0508018

Muhammad N, Sinha R, Krishnan R, Patterson CL, Haught RC, Harms HH, Seville R (2010) Evaluating a composite cartridge for small system drinking water treatment. J Water Health 8(2):212–223. https://doi.org/10.2166/wh.2009.156

Mena Aguilar KM, Amano Y, Machida M (2016) Ammonium persulfate oxidized activated carbon fiber as a high capacity adsorbent for aqueous Pb(II). J Environ Chem Eng 4:4644–4652. https://doi.org/10.1016/j.jece.2016.10.028

Takeuchi K, Amano Y, Machida M, Imazeki F (2015) Batch and fixed-bed column adsorption of Cd(II) from aqueous solution onto oxidized bead-shaped activated carbon. J Chem Eng Jpn 48(2):123–126. https://doi.org/10.1252/jcej.14we187

Iida T, Amano Y, Machida M, Imazeki F (2013) Effect of surface property of activated carbon on adsorption of nitrate ion. Chem Pharm Bull 61(11):1173–1177. https://doi.org/10.1248/cpb.c13-00422

Machida M, Goto T, Amano Y, Iida T (2016) Adsorptive removal of nitrate from aqueous solution using nitrogen doped activated carbon. Chem Pharm Bull 64(11):1555–1559. https://doi.org/10.1248/cpb.c16-00368

Goto T, Amano Y, Machida M (2017) Surface modification of carbonized melamine sponge by methyl iodide for the efficient removal of nitrate ions. TANSO 276:2–7. https://doi.org/10.7209/tanso.2017.2

Machida M, Sakamoto T, Sato K, Goto T, Amano Y (2018) Adsorptive removal of nitrate from aqueous phase using steam activated and thermal treated polyacrylonitrile (PAN) fiber. J Fiber Sci Technol 74(7):158–164. https://doi.org/10.2115/fiberst.2018-0023

Machida M, Amano Y (2018) Adsorptive removal of nitrate from water using modified activated carbon fibers. J Ion Exch 29(3):166–169. https://doi.org/10.5182/jaie.29.166

Yoo P, Amano Y, Machida M (2018) Adsorption of nitrate in aqueous solution on nitrogen-doped activated carbon fibers prepared by chemical vapor deposition. Korean J Chem Eng 35(12):2468–2473. https://doi.org/10.1007/s11814-018-0151-4

Kaneko K, Ishii C (1992) Superhigh surface area determination of microporous solids. Colloids Surf 67:203–212

Pels JR, Kapteijn F, Moulijin JA, Zhu Q, Thomas KM (1995) Evolution of nitrogen functionalities in carbonaceous materials during pyrolysis. Carbon 33(11):1641–1653. https://doi.org/10.1016/0008-6223(95)00154-6

Ota K, Amano Y, Aikawa M, Machida M (2013) Removal of nitrate ions from water by activated carbons (ACs)—influence of surface chemistry of ACs and coexisting chloride and sulfate ions. Appl Surf Sci 276:838–842. https://doi.org/10.1016/j.apsusc.2013.03.053

Mazarji M, Aminzadeh B, Baghdadi M, Bhatnagar A (2017) Removal of nitrate from aqueous solution using modified granular activated carbon. J Mol Liq 233:139–148. https://doi.org/10.1016/j.molliq.2017.03.004

Kilpimaa S, Runtti H, Kangas T, Lassi U, Kuokkanen T (2015) Physical activation of carbon residue from biomass gasification: Novel sorbent for the removal of phosphates and nitrates from aqueous solution. J Ind Eng Chem 21:1354–1364. https://doi.org/10.1016/j.jiec.2014.06.006

Nunell GV, Fernandez ME, Bonelli PR, Cukierman AL (2015) Nitrate uptake improvement by modified activated carbons developed from two species of pine cones. J Colloid Interface Sci 440:102–108. https://doi.org/10.1016/j.jcis.2014.10.058

Sato S, Yoshihara K, Moriyama K, Machida M, Tatsumoto H (2007) Influence of activated carbon surface acidity on adsorption of heavy metal ions and aromatics from aqueous solution. Appl Surf Sci 253(20):8554–8559. https://doi.org/10.1016/j.apsusc.2007.04.025

Dioum A, Hamoudi S (2014) Mono- and quaternary-ammonium functionalized mesoporous silica materials for nitrate adsorptive removal from water and wastewaters. J Porous Mater 21(5):685–690. https://doi.org/10.1007/s10934-014-9815-6

Bitter JH, van Dommele S, de Jong KP (2010) On the virtue of acid–base titrations for the determination of basic sites in nitrogen doped carbon nanotubes. Catal Today 150:61–66. https://doi.org/10.1016/j.cattod.2009.09.008

Acknowledgements

Central Research Laboratory of Cosmo Oil Co., Ltd. is sincerely acknowledged for supporting X-ray photoelectron spectroscopy (XPS) analysis, and Center for Analytical Instrumentation, Chiba University, is greatly appreciated for conducting elemental analysis. Gratitude is greatly extended to Ms. Shizuka Ishibashi, Safety and Health Organization, Chiba University, for her dedicated support in the experiments. We also thank Prof. Dr. Fumio Imazeki, the head of Safety and Health Organization, Chiba University, for his encouragement and the financial support of our study.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Machida, M., Yoo, P. & Amano, Y. Adsorption of nitrate from aqueous phase onto nitrogen-doped activated carbon fibers (ACFs). SN Appl. Sci. 1, 323 (2019). https://doi.org/10.1007/s42452-019-0333-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-019-0333-7