Abstract

The application of titanium oxide engineered nanomaterials (TiO2 ENMs) in products is dominant in sunscreens and can be released into water systems with relative ease during sunscreen use. The current study examined the physico-chemical properties of the TiO2 ENMs extracted from three sunscreens (SUN A, B, and C) and also released during bathing into deionised and tap water. The TiO2 ENMs were identified in all the sunscreen extract samples using scanning and transmitting electron microscopy (SEM and TEM). The mode length of the ENMs measured with SEM were 67.6, 69.8, and 51.8 nm for SUN A, B, and C respectively whereas their width were 31.3, 38.7, and 27.7 nm. From TEM analysis the ENMs length and width mode sizes respectively were 73.9 and 14.5 nm for SUN A, 81.5 and 16.3 nm for SUN B, and 44.7 and 14.0 nm for SUN C. The Ti content of the sunscreens was 1.9, 0.6, and 0.5% w/w respectively for SUN A, B, and C. During bathing TiO2 ENMs were released into wastewater and were in the size range of 47–218, 102–153, and 92–138 nm for SUN A, B, and C respectively in DI wastewater. In tap wastewater they were 100–241, 100–477, and 67–150 nm SUN A, B, and C respectively. The determined environmental concentrations for the ENMs in DI wastewater ranged 0.2–1.16 µg/L, whereas in tap wastewater it was 0.16–0.17 µg/L. The morphologies of the extracted and released ENMs were a mixture of rods, plates, irregular, and near spherical. The released Ti quantity significantly differed between DI and tap wastewater for SUN B and C, indicating the influence of wastewater quality in the exposure profile of ENMs in water systems.

Similar content being viewed by others

1 Introduction

Advances made in nanotechnology have resulted to the enhancement of products using engineered nanomaterials (ENMs) based on their nanoscale driven physico-chemical properties. Such products are generally called nano-enabled products (NEPs) and can vary between personal care, health and fitness, clothing, cleaning, sporting products and the popular ENMs used are TiO2, ZnO, Ag, and carbon-based ENMs [22, 61, 66]. For instance, conventional TiO2 has been widely used for UV filtration in personal care products [42, 56], colouring agents in paints and plastics [14, 58], however nano TiO2 has gained popularity [40] due to enhanced performance on UV filtering [35, 53], transparency to visible light, antibacterial properties [26], photocatalytic properties [3], and is the most highly produced ENMs type [41, 60]. For almost a century bulk silver has been an effective antibacterial agent [37, 50] but nanoscale Ag is amongst the top produced ENMs [60] due to enhanced antibacterial activity [28] and is mostly applied in personal care products and sunscreens [22, 61, 66]. The popularity of ENMs is for instance exhibited by the rise in nano-enabled products from 54 to 1814 between 2005 in 2015 [61]. Others have estimated a total of 1432 in Singapore [66], 2231 in Europe [22].

The increasing production and use of NEPs raises the likelihood for the environmental release of ENMs across the product life-cycle, predominantly during use and disposal phases [41]. The unintended release of ENMs is estimated to be high in landfills followed by water, soils and air in the descending order [27]. The current state of knowledge pertaining the potential risks of nanotechnology is largely drawn from studies with pristine ENMs and as such little information exists with regards to the environmental exposure and effects from NEPs’ sources. The inadequacy of pristine ENMs as models for risk assessment has been argued by release studies and reviews- showing that released ENMs are highly embedded within the matrix of the product, and thus raise calls for more release and aging studies [13, 33, 38, 39, 49, 51, 52].

The released state of ENMs from product usage scenarios presents a case that is of high environmental relevance but little information has been generated in such studies due to the information paucity surrounding protocols for releasing ENMs. However, there is a rising call for release studies [51] to closely resemble realistic exposure scenarios. Generally global efforts to regulate NEPs have had limited success due to the paucity of human and environmental health and safety data, lack of robust data on sources and exposure estimates, un-readiness of the regulatory framework, inconsistent terminology, amongst the top challenges [10, 15, 16] where regulations exist they are highly specific to commercial sector or product use category [31].

Sunscreens, specifically those enabled with TiO2 ENMs are proportionally dominant NEPs across global markets [47, 54, 61, 66] and are a top priority source of nanopollution into water systems due to the ease at which they can emit ENMs based on the loci of ENMs and their market domination [17, 23, 24]. Titanium oxide (TiO2) ENMs are amongst the most produced for application in NEPs such as cosmetics, sunscreens, and paints [30, 57, 65] and have been prioritised for considerable risk to freshwater systems [45, 46] as approximately 90% of TiO2 ENMs released into freshwater originate from sunscreens [19]. Sunscreens are most frequently incorporated with TiO2 ENMs [22, 61, 66] as the ENMs are highly effective UV filters thus offering enhanced protection against sunlight effects relative to bulk counterparts [12]. The amount of TiO2 ENMs in sunscreens can be as high as 14–90 µg/mg [63] 25% (w/w) concentrations [59]. As such TiO2 ENMs are expected to be amongst the nanopollutants occurring at high concentration (high ppb to lower ppt) in wastewater and environmental water systems [20, 43]. It is in this context that sunscreens were selected in the current study as a model for NEPs to examine TiO2 ENMs environmental exposure. Research efforts pertaining sunscreens and nanopollution have largely focussed on extraction protocols for ENMs and determination of their physico-chemical properties [6, 7, 12, 36, 44, 55] and fewer towards release assessment [9, 18, 64]. Therefore more data is still required with respect to the released ENMs and their characteristics in the environment. The current study examined the physicochemical properties of extracted and released TiO2 ENMs from three commercial sunscreens, thus was unique in adopting a life cycle assessment approach by focusing at the product fabrication (extraction of ENMs) and product use (release of ENMs) phases. The release assessment was the first of its kind in using plastic dolls as a substrate to mimic sunscreen application on human skin. Herein, doll bathwater was referred to as wastewater from which released TiO2 ENMs were obtained.

2 Materials and methods

2.1 Extraction of ENMs

Hexane (95%), hydrogen fluoride anhydrous (HF) (40%), hydrogen peroxide (H2O2) (30%) and methanol (99.9%) of analytical grade were purchased from Sigma-Aldrich (Pretoria, South Africa) and were used without further purification. Boric acid (H3BO3) was purchased from Associated Chemical Enterprise (South Africa), scandium (Sc) internal standard and Ti standard solution were purchased from De Bruyn Spectroscopic Solutions (South Africa). Three sunscreens (SUN A, B, C) all labelled as containing nano-TiO2 ENMs were purchased over the counter at a retail shop. Their sun protection factors (SPF) were 30, 40, and 50 for SUN A, SUN B, and SUN C respectively. The extraction procedure was modified from methods developed elsewhere [11, 48]. Briefly; for each sunscreen 10 g was weighed into a clean weighing boat and then transferred into a 250 mL Schott® bottle containing 50 mL deionised (DI) water. The mixture was bath-sonicated at 30 °C for 30 min at 005 power level followed by addition of 50 mL methanol and further sonication for 30 min. Following sonication 50 mL hexane was added and the mixture homogenised by hand shaking for 30 s, followed by centrifugation at 5310 rpm for 20 min. The supernatant was pipetted out and the pellet was transferred into a clean centrifuge tube and centrifuged for a further 20 min at 5310 rpm. The supernatant was removed and 25 mL hexane added to the pellet followed by another centrifugation at 5310 rpm for 20 min, and the obtained pellet was transferred into a watch glass and dried with nitrogen (N2) gas.

2.2 Release study

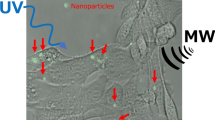

Children plastic dolls (height 38.9–39.6 cm; weight of 96.6–99.6 g) were purchased from a retail shop in Pretoria, South Africa. Adopted from [27], an amount 2 g per sunscreen was applied to the dolls to simulate application to a human body. Following sunscreen application, the dolls were exposed to natural sunlight then re-applied sunscreen after 2 h, followed by further sunlight exposure for 2 h 30 min, after which the dolls were washed with 500 mL of deionised (DI) water (15 mΩ/cm−1) and tap water. The DI water was selected as a negative control due to the absence of ions whereas tap water selection was on the basis that nanopollutants arising from sunscreens application will be released into tap water during bathing. The washing water was collected and inhere referred to as wastewater from which the physico-chemical properties TiO2 ENMs were determined. All the experiments were run in triplicate.

2.3 Characterisation of the ENMs

2.3.1 Extracted samples

The dried pellet samples obtained from the extraction step were transferred into clean centrifuge tubes containing 50 mL de-ionised water and homogenised by hand shaking for 30 s. For rapid screening of Ti in waste water, the samples were analysed with UV/Vis spectrometer (UV/Vis, lamda 750S). The samples were filtered by 0.45 μm syringe filter, transferred into a quartz cuvette with a path length of 10 mm, and analysed at wavelength range of 200 to 500 nm at 1 unit interval. Screening for ENMs was performed with the nanoparticle tracking analysis (NTA, NS500). The extracted 10 mg pellet sample was mixed with 5 mL of deionised water in a 15 mL centrifuge tube, sonicated at 15 °C for 30 min. The sample was filtered with a 0.45 μm syringe filter before analysis. For each sample a 60 s video was captured at a camera level ranging from 4 to 15, this was triplicated.

The extracted samples were also examined with electron microscopy viz; scanning electron microscopy (SEM, Carl Zeiss, Germany) and Transmission Electron Microscopy (HRTEM, JEOL JEM 2100, Japan) both coupled with energy dispersed spectroscopy (EDS). For SEM analysis the dried extract samples were carbon coated and placed in a Turbo carbon evaporator for 5 min at 6 × 10−3 mbar vacuum. The samples were analysed at an accelerating voltage of 5 kV and EDS used to determine the elemental composition of the sample. For analysis with TEM the dry powder extract samples were mixed with 500 μL deionised water in a 1.5 mL microtube and bath-sonicated for 30 s at 005 power level. A carbon coated Cu grid was then dipped into the solution and left to dry overnight prior analysis. The samples were examined at 200 kV and coupled with EDS for elemental determination. Multiple images of each sample were taken for subsequent particle size analysis with the open source Image J software.

Inductively coupled plasma mass spectrometry (ICP-MS, Icap Q, Thermo Fisher Scientific, USA) was used to determine the total Ti concentration in the sunscreens. Sample preparation was initiated by microwave acid digestion following the protocol by Contado and Pagnoni [11]. Briefly; for each sunscreen 200 mg was transferred into a dry 100 mL TFM vessel followed by the addition of the following solvents: 12 mL HNO3 (70%), 6 mL HF (40%) and 2 mL H2O2 (30%). The vessel was sealed and placed in a high-pressure rotor and the microwave digestion program was set at the power of 250–550 W and 120–220 °C for 15 min. The samples were allowed to cool at room temperature and 300 mg H3BO3 was added to the vessel and microwave digestion was repeated following the programme described earlier. Once digestion was complete, the samples were allowed to cool at room temperature and transferred into 50 mL centrifuge tubes in preparation for ICP-MS analysis. A volume 50 μL of the digested samples was transferred into a 50 mL centrifuge tube, then 25 μL Sc internal standard (500 μg/L) and 385 μL HNO3 (0.5%) were added and topped up to 50 mL with deionised water. The Ti standard solutions of 0, 5, 25, 50, 100, 250, 500, 750, 1000 μg/L were prepared for method verification. Total Ti in the samples was then determined with ICP-MS.

2.3.2 Release samples

The presence of TiO2 ENMs was screened with the UV–Vis and the NTA. For UV–Vis analysis the released wastewater samples were diluted tenfolds with DI water, filtered with 0.45 μm syringe and 2.5 mL was transferred into a 3.5 mL quartz cuvette and analysed at 200–500 nm at 1 unit interval. For analysis with the NTA, the wastewater samples were sonicated at 005 power level at 30 °C for 30 min before analysis. Wastewater samples of 1.5 mL were transferred into 1.5 mL tubes and analysed by capturing a 60 s video at the camera level from 4 to 15.

Samples for SEM analysis were prepared by centrifuging the wastewater for 20 min at 5310 rpm, and the pellet was dried at room temperature. Samples for SEM analysis were carbon coated and placed in a Turbo carbon evaporator (EMITECH–K950X) to evaporate the surface of samples for 5 min at 6 × 10−3 mbar vacuum, then analysed at an accelerating voltage of 5 kV. For analysis with TEM the carbon coated Cu grids were dipped into wastewater samples and left to dry at room temperature. The Cu grids were then analysed with TEM examined at 200 kV. Both TEM and SEM were coupled with EDS, and minimum of five images were captured per sample. The amount of Ti in the wastewater samples was determined with ICP-MS following microwave digestion of the samples as earlier described.

2.4 Statistical analysis

The JMP Pro 10 software data analysis software, specifically the analysis of variance (ANOVA) was used to test differences between treatments at α = 0.05.

3 Results and discussion

3.1 Extraction

The results from the analysis of the extracted pellets samples suggested successful extraction of TiO2 ENMs. From the UV–Vis analysis the sunscreens exhibited a spectra with maximum peaks at 332, 319, and 269 nm for SUN A, B, and C respectively (Fig. 1). The maximum absorbance peak of Ti ranges between 250 and 450 nm depending on irradiation, physico-chemical nature of the sample and surface impurities [2, 25, 34]. The spectra of sunscreen extracted TiO2 ENMs has not been examined previously but the currently determined range indicated samples absorptive capacity for UVB (290–315 nm) and UVA (315–400 nm) radiation, a sought after characteristic of nano TiO2 enabled sunscreens [55]. Analysis with the NTA confirmed the presence of ENMs in all samples with hydrodynamic sizes (mode) of 81.1, 121.3 and 91.4 nm for SUN A, B, and C respectively. The NTA was not used for accurate size measurements but rather for screening for the presence of ENMs, since the NTA size is derived assuming spherical morphology of the ENMs whilst morphologically poly-dispersed ENMs were anticipated in the samples.

Analysis undertaken with SEM revealed the presence of ENMs in the extracts and elemental profiling confirmed the identity of TiO2 ENMs (Fig. 2, Table 1). The TiO2 ENMs were agglomerated and were poly-dispersed in size and morphology, and in some instances embedded in the organic matrix of the product, thus indicative of incomplete extraction efficiency. Elemental analysis suggested that the TiO2 ENMs were coated with silica (Si) and aluminium (Al); surface functionalization that improves the photostability of TiO2 ENMs [29, 62].

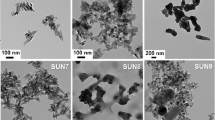

The presence of TiO2 ENMs in the three sunscreens was further confirmed through high resolution TEM analysis (Fig. 3) where they were found to have a combined range of 44.4–96.3 and 10.6–25.9 nm in length and width respectively (Table 1). The morphology was similar to observed from SEM analysis. In general TiO2 ENMs in sunscreen extracts have been reported to be morphologically poly-dispersed [6, 12, 21, 32, 44, 55]. Overall the current findings were complementary to earlier reports. Total Ti was found to be 1.9, 0.6, and 0.5% w/w respectively for SUN A, B, and C. Such concentrations were considered to be on lower end compared to reports where Ti in sunscreens has been estimated below 5% w/w [9, 27] or can be as high as 25% w/w [59, 63]. It was interesting to note that Ti concentration was inverse to the sunscreen SPF in the examined sunscreens, a directly related trend was anticipated with Ti content being indicative of SPF level. Such requires more focussed investigation to establish the relationship between sunscreen Ti content and its SPF level.

3.2 Release

The presence of ENMs (of unknown species) in DI and tap wastewaters was indicated by the NTA. In DI wastewater particles with mode size of 108.4, 117.3 and 103 nm for SUN A, B, and C respectively, and in tap wastewater it was 85.3, 87.6, and 94 nm for SUN A, B, and C respectively. There was a characteristic rise in absorbance across all the samples at 270–390 nm (Fig. 4) which was thought to reflect UVB (290–315 nm) and UVA (315–400 nm) absorptive capacity as observed from the extract samples (Fig. 1), which strongly suggested the presence of UV absorptive TiO2 ENMs. It was noteworthy that there was distinct change in the absorbance profile of all the sunscreen samples between DI and tap wastewater variations. The surface properties of TiO2 influence its photo-activity [2, 25, 34] and in this instance the results demonstrated that the behaviour of TiO2 nanopollutants in water resources will be influenced by the water quality composition of the water. Furthermore, the results suggested that water quality influence on TiO2 ENMs photo-activity can alter their bioactive and toxicity profiles which largely are derived from photo generation of reactive oxygen species [8].

Analysis with SEM confirmed the release of TiO2 ENMs into both wastewater types (Fig. 5; Table 2). The released ENMs were predominantly embedded in the sunscreen matrix and not as free entities, similar observations have been reported previously [9, 18]. The findings strengthen the calls for more release and aging type of studies when examining the environmental implications of ENMs from NEPs, as experimentally it has been demonstrated that the product matrix is often associated with released ENMs [1], and data drawn from studies with pristine ENMs is of poor value. Results obtained from TEM coupled with EDS also indicated the release of TiO2 ENMs in both wastewater types (Fig. 6). The ENMs’ sizes in DI water ranged between 32.1 and 102.8 nm and in Tap water the range was 77.6–139.6 nm (Table 2), and thus relatively similar in both wastewater types. The ENMs were rod, plate, and needle like in morphology; other have also reported similarly shaped TiO2 ENMs from sunscreens [9, 18].

Having achieved a 94–99% (R = 0.9992) recovery rate, average total Ti released in DI wastewater was 0.2, 0.8, and 1.16 µg/L whereas in tap wastewater it was 0.16, 0.17, and 0.7 µg/L from SUN A, B and C respectively (Fig. 7). The general trend was that the least Ti was released from SUN A and highest from SUN C across wastewater types, and on average less Ti was released in Tap relative to DI water except in the case of SUN A. The results obtained from UV–Vis and ICP-MS analysis point to the influence of wastewater quality on the release extent of TiO2 ENMs into water, in this instance possibly resulting from the complexation of the sunscreen contents with minerals present in Tap but lacking in DI water; thus inhibiting release of the ENMs. It is therefore likely that water hardness plays a role in the release rate of TiO2 ENMs from sunscreens, the demonstrated influence of inorganic ions (e.g. Ca2+, Na+, Mg2+) on the fate and behaviour of metal and metal oxide ENMs in water media [4, 5] adds credence to such a hypothesis. Furthermore, the observed trend of increasing Ti content with increasing SPF suggested that the TiO2 were the main UV absorbing agent whose concentration in the formulation would have been increased for enhanced sun protection properties. It is noteworthy that although such a trend was anticipated it was not observed from extracted Ti content, possibly resulting from extraction efficiency.

4 Concluding remarks

The TiO2 ENMs were detected in all the sunscreens, thus confirming the “nano” claim by the manufacturers. The physico-chemical properties of the ENMs were comparable. The extraction method was efficient in separating the organic and inorganic matter of the sunscreen although organics traces were still detected in some instances, however this did not cause interfere with sample analysis. We demonstrated that the value of utilising the UV–Vis and NTA as rapid screening tools for the presence of Ti and ENMs respectively. Generally SEM and TEM are time consuming, costly and require specialized skills to operate, and are not widely accessible to researchers; thus screening for ENMs using cheaper and rapid tools prior electron microscopy analysis has an advantage of avoiding false negatives coupled with time and financial cost. The use of plastic dolls in the release study was a successful replacement model for human and pig skin options which require ethical clearance for scientific research purposes. However we recommend that future studies using plastic doll models investigate their adsorptive capacity in order to establish sunscreen quantities retained by the surfaces. We observed significantly different amounts of released Ti from sunscreens C and D, indicating the influence of wastewater chemistry on the release pattern of the ENMs from sunscreens; this has environmental implications and should be explored further to incorporate effects assessment.

References

Amorim MJB, Lin S, Schlich K, Navas JM, Brunelli A, Neubauer N et al (2018) Environmental impacts by fragments released from nanoenabled products: a multiassay, multimaterial exploration by the SUN approach. Environ Sci Technol 52(3):1514–1524

Atif M, Farooq WA, Fatehmulla A, Aslam M, Ali SM (2015) Photovoltaic and impedance spectroscopy study of screen-printed TiO2 based CdS quantum dot sensitized solar cells. Materials 8(1):355–367

Auffan M, Pedeutour M, Rose J, Masion A, Ziarelli F, Borschneck D et al (2010) Structural degradation at the surface of a TiO2-based nanomaterial used in cosmetics. Environ Sci Technol 44(7):2689–2694

Baalousha M, Ju-Nam Y, Cole PA, Hriljac JA, Jones IP, Tyler CR et al (2012) Characterization of cerium oxide nanoparticles—part 2: nonsize measurements. Environ Toxicol Chem 31(5):994–1003

Baalousha M, Lead J (2015) Characterization of nanomaterials in complex environmental and biological media, vol 8. Elsevier, Amsterdam

Bairi VG, Lim J-H, Fong A, Linder SW (2017) Size characterization of metal oxide nanoparticles in commercial sunscreen products. J Nanopart Res 19(7):256–266

Bairi VG, Lim J-H, Quevedo IR, Mudalige TK, Linder SW (2016) Portable X-ray fluorescence spectroscopy as a rapid screening technique for analysis of TiO2 and ZnO in sunscreens. Spectrochim Acta, Part B 116:21–27

Bi Y, Zaikova T, Schoepf J, Herckes P, Hutchison JE, Westerhoff P (2017) The efficacy and environmental implications of engineered TiO2 nanoparticles in a commercial floor coating. Environ Sci Nano 4(10):2030–2042

Botta C, Labille J, Auffan M, Borschneck D, Miche H, Cabié M et al (2011) TiO2-based nanoparticles released in water from commercialized sunscreens in a life-cycle perspective: structures and quantities. Environ Pollut 159(6):1543–1550

Commission European Union (2011) Commission recommendation of 18 October 2011 on the definition of nanomaterial (2011/696/EU). Official Journal of the European Communities: Legis, pp 275–277

Contado C, Pagnoni A (2008) TiO2 in commercial sunscreen lotion: flow field-flow fractionation and ICP-AES together for size analysis. Anal Chem 80(19):7594–7608

Dan Y, Shi H, Stephan C, Liang X (2015) Rapid analysis of titanium dioxide nanoparticles in sunscreens using single particle inductively coupled plasma–mass spectrometry. Microchem J 122:119–126

Duncan TV (2014) Release of engineered nanomaterials from polymer nanocomposites: the effect of matrix degradation. ACS Appl Mater Interfaces 7(1):20–39

EPA (2010) Science and research at the U.S. Environmental Protection Agency, pp 1–80. Retrieved from www.epa.gov/si

EU (2006) Regulation (EC) No 1907/2006—registration, evaluation, authorisation and restriction of chemicals (REACH)—safety and health at work—EU-OSHA. Retrieved 3 Oct 2018, from https://osha.europa.eu/en/legislation/directives/regulation-ec-no-1907-2006-of-the-european-parliament-and-of-the-council

Food and Drug Administration (2016) Sunscreen drug products for over-the-counter human use, 21CFR352.10. Retrieved from https://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfcfr/CFRSearch.cfm?CFRPart=352

Foss Hansen S, Larsen BH, Olsen SI, Baun A (2007) Categorization framework to aid hazard identification of nanomaterials. Nanotoxicology 1(3):243–250

Gondikas AP, von der Kammer F, Reed RB, Wagner S, Ranville JF, Hofmann T (2014) Release of TiO2 nanoparticles from sunscreens into surface waters: a one-year survey at the old Danube recreational Lake. Environ Sci Technol 48(10):5415–5422

Gottschalk F, Lassen C, Kjoelholt J, Christensen F, Nowack B (2015) Modeling flows and concentrations of nine engineered nanomaterials in the Danish environment. Int J Environ Res Public Health 12(5):5581–5602

Gottschalk F, Ort C, Scholz RW, Nowack B (2011) Engineered nanomaterials in rivers–exposure scenarios for Switzerland at high spatial and temporal resolution. Environ Pollut 159(12):3439–3445

Hanigan D, Truong L, Schoepf J, Nosaka T, Mulchandani A, Tanguay R, Westerhoff P (2018) Trade-offs in ecosystem impacts from nanomaterial versus organic chemical ultraviolet filters in sunscreens. Water Res 139:281–290

Hansen SF, Heggelund LR, Besora PR, Mackevica A, Boldrin A, Baun A (2016) Nanoproducts–what is actually available to European consumers? Environ Sci Nano 3(1):169–180

Hansen SF, Jensen KA, Baun A (2014) NanoRiskCat: a conceptual tool for categorization and communication of exposure potentials and hazards of nanomaterials in consumer products. J Nanopart Res 16(1):2195–2219

Hansen SF, Michelson ES, Kamper A, Borling P, Stuer-Lauridsen F, Baun A (2008) Categorization framework to aid exposure assessment of nanomaterials in consumer products. Ecotoxicology 17(5):438–447

Ingale SV, Wagh PB, Tripathi AK, Srivastav RS, Singh IK, Bindal RC, Gupta SC (2012) TiO2-polysulfone beads for use in photo oxidation of rhodamine B. Soft Nanosci Lett 2(04):67–70

Janczarek M, Zielińska-Jurek A, Markowska I, Hupka J (2015) Transparent thin films of Cu–TiO2 with visible light photocatalytic activity. Photochem Photobiol Sci 14(3):591–596

Keller AA, Vosti W, Wang H, Lazareva A (2014) Release of engineered nanomaterials from personal care products throughout their life cycle. J Nanopart Res 16(7):2489–2498

Küünal S, Kutti S, Rauwel P, Guha M, Wragg D, Rauwel E (2016) Biocidal properties study of silver nanoparticles used for application in green housing. Int Nano Lett 6(3):191–197

Labille J, Feng J, Botta C, Borschneck D, Sammut M, Cabie M et al (2010) Aging of TiO2 nanocomposites used in sunscreen. Dispersion and fate of the degradation products in aqueous environment. Environ Pollut 158(12):3482–3489

Łabuz P, Sadowski Rafałand Stochel G, Macyk W (2013) Visible light photoactive titanium dioxide aqueous colloids and coatings. Chem Eng J 230:188–194

Lai RWS, Yeung KWY, Yung MMN, Djurišić AB, Giesy JP, Leung KMY (2018) Regulation of engineered nanomaterials: current challenges, insights and future directions. Environ Sci Pollut Res 25(4):3060–3077

Lewicka ZA, Benedetto AF, Benoit DN, William WY, Fortner JD, Colvin VL (2011) The structure, composition, and dimensions of TiO2 and ZnO nanomaterials in commercial sunscreens. J Nanopart Res 13(9):3607–3617

Liou P, Nguyen THD, Lin M (2018) Measurement of engineered nanoparticles in consumer products by surface-enhanced Raman spectroscopy and neutron activation analysis. J Food Meas Charact 12(2):736–746

Liu HH, Cohen Y (2014) Multimedia environmental distribution of engineered nanomaterials. Environ Sci Technol 48(6):3281–3292

Lorenz C, Tiede K, Tear S, Boxall A, Von Goetz N, Hungerbühler K (2010) Imaging and characterization of engineered nanoparticles in sunscreens by electron microscopy, under wet and dry conditions. Int J Occup Environ Health 16(4):406–428

Lu PJ, Cheng WL, Huang SC, Chen YP, Chou HK, Cheng HF (2015) Characterizing titanium dioxide and zinc oxide nanoparticles in sunscreen spray. Int J Cosmet Sci 37(6):620–626

Luoma SN (2008) Silver nanotechnologies and the environment. Proj Emerg Nanotechnol Rep 15:1–72

Mackevica A, Foss Hansen S (2016) Release of nanomaterials from solid nanocomposites and consumer exposure assessment—a forward-looking review. Nanotoxicology 10(6):641–653

Mackevica A, Olsson ME, Hansen SF (2018) Quantitative characterization of TiO2 nanoparticle release from textiles by conventional and single particle ICP-MS. J Nanopart Res 20(1):6–16

Macwan DP, Dave PN, Chaturvedi S (2011) A review on nano-TiO2 sol–gel type syntheses and its applications. J Mater Sci 46(11):3669–3686

Mitrano DM, Motellier S, Clavaguera S, Nowack B (2015) Review of nanomaterial aging and transformations through the life cycle of nano-enhanced products. Environ Int 77:132–147

Mu L, Sprando RL (2010) Application of nanotechnology in cosmetics. Pharm Res 27(8):1746–1749

Mueller NC, Nowack B (2008) Exposure modeling of engineered nanoparticles in the environment. Environ Sci Technol 42(12):4447–4453

Müller D, Cattaneo S, Meier F, Welz R, de Vries T, Portugal-Cohen M et al (2016) Inverse supercritical fluid extraction as a sample preparation method for the analysis of the nanoparticle content in sunscreen agents. J Chromatogr A 1440:31–36

Musee N (2017) A model for screening and prioritizing consumer nanoproduct risks: a case study from South Africa. Environ Int 100:121–131

Musee N, Thwala M, Nota N (2011) The antibacterial effects of engineered nanomaterials: implications for wastewater treatment plants. J Environ Monit 13(5):1164–1183

Nanodb.dk (2018) The nanodatabase. Retrieved 21 Aug 2018, from http://nanodb.dk/

Nischwitz V, Goenaga-Infante H (2012) Improved sample preparation and quality control for the characterisation of titanium dioxide nanoparticles in sunscreens using flow field flow fractionation on-line with inductively coupled plasma mass spectrometry. J Anal At Spectrom 27(7):1084–1092

Nowack B, Boldrin A, Caballero A, Hansen SF, Gottschalk F, Heggelund L et al (2016) Meeting the needs for released nanomaterials required for further testing: the SUN approach. Environ Sci Technol 50(6):2747–2753

Nowack B, Krug HF, Height M (2011) 120 years of nanosilver history: implications for policy makers. Environ Sci Technol 45(4):1177–1183

Nowack B, Mitrano DM (2017) Procedures for the production and use of synthetically aged and product released nanomaterials for further environmental and ecotoxicity testing. NanoImpact 10:70–80

Nowack B, Ranville JF, Diamond S, Gallego-Urrea JA, Metcalfe C, Rose J et al (2012) Potential scenarios for nanomaterial release and subsequent alteration in the environment. Environ Toxicol Chem 31(1):50–59

Paul R, Bautista L, la Varga M, Botet JM, Casals E, Puntes V, Marsal F (2010) Nano-cotton fabrics with high ultraviolet protection. Text Res J 80(5):454–462

PEN (2018) The project on emerging nanotechnologies. Consumer Products Inventory. Retrieved 21 Aug 2018, from http://www.nanotechproject.org/cpi/products/

Philippe A, Košík J, Welle A, Guigner J-M, Clemens O, Schaumann GE (2018) Extraction and characterization methods for titanium dioxide nanoparticles from commercialized sunscreens. Environ Sci Nano 5(1):191–202

Popov AP, Lademann J, Priezzhev AV, Myllylä RA (2005) Effect of size of TiO2 nanoparticles embedded into stratum corneum on ultraviolet-A and ultraviolet-B sun-blocking properties of the skin. J Biomed Opt 10(6):64037

Rajh T, Dimitrijevic NM, Bissonnette M, Koritarov T, Konda V (2014) Titanium dioxide in the service of the biomedical revolution. Chem Rev 114(19):10177–10216

Raliya R, Biswas P, Tarafdar JC (2015) TiO2 nanoparticle biosynthesis and its physiological effect on mung bean (Vigna radiata L.). Biotechnol Rep 5:22–26

Salvador A, Chisvert A (2005) Sunscreen analysis: a critical survey on UV filters determination. Anal Chim Acta 537(1–2):1–14

Sun TY, Gottschalk F, Hungerbühler K, Nowack B (2014) Comprehensive probabilistic modelling of environmental emissions of engineered nanomaterials. Environ Pollut 185:69–76

Vance ME, Kuiken T, Vejerano EP, McGinnis SP, Hochella MF Jr, Rejeski D, Hull MS (2015) Nanotechnology in the real world: redeveloping the nanomaterial consumer products inventory. Beilstein J Nanotechnol 6(1):1769–1780

Wakefield G, Green M, Lipscomb S, Flutter B (2004) Modified titania nanomaterials for sunscreen applications–reducing free radical generation and DNA damage. Mater Sci Technol 20(8):985–988

Weir A, Westerhoff P, Fabricius L, Hristovski K, Von Goetz N (2012) Titanium dioxide nanoparticles in food and personal care products. Environ Sci Technol 46(4):2242–2250

Windler L, Lorenz C, von Goetz N, Hungerbuhler K, Amberg M, Heuberger M, Nowack B (2012) Release of titanium dioxide from textiles during washing. Environ Sci Technol 46(15):8181–8188

Yang Y, Westerhoff P (2014) Presence in, and release of, nanomaterials from consumer products. Nanomaterial 811:1–17

Zhang Y, Leu Y-R, Aitken RJ, Riediker M (2015) Inventory of engineered nanoparticle-containing consumer products available in the Singapore retail market and likelihood of release into the aquatic environment. Int J Environ Res Public Health 12(8):8717–8743

Acknowledgements

This research was supported by funding from the Department of Science and Technology (DST), South Africa under the Nanotechnology Health Safety and the Environment research platform.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nthwane, Y.B., Tancu, Y., Maity, A. et al. Characterisation of titanium oxide nanomaterials in sunscreens obtained by extraction and release exposure scenarios. SN Appl. Sci. 1, 312 (2019). https://doi.org/10.1007/s42452-019-0329-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-019-0329-3