Abstract

The dielectric behaviour of a polymer/ceramic composite (PCC) based on ferroelectric polymer [polyvinylidene fluoride (PVDF)] and nano-barium titanate (n-BaTiO3), prepared under the novel cold pressing method, was investigated. Large enhancement of effective dielectric constant (ɛeff ~ 450) with lower loss tangent (tan δ ~ 0.9) at 50 Hz was observed for the PCC with 0.60 as the volume fraction of n-BaTiO3 into the PVDF matrix. The enhancement of ɛeff is attributed to the large interfacial polarisation arising due to the charge storage at the interfaces of the spherulites of PVDF and at the polymer/filler interfaces of PCC. The dielectric results have been explained on the basis of sum effect with the help of the standard Yamada model at 1 kHz, while the low-frequency dielectric behaviour has been explained qualitatively as a combination of both interfacial polarisation at the interfaces of the spherulites and the sum effect of the Yamada model. The achieved lower tan δ for the PCC as compared to the polymer/metal composites (PMC) is attributed to the highly insulating nature of PVDF and semiconducting n-BaTiO3. The thermal stability of the composites is also maintained due to the higher melting temperature (170 °C) of PVDF. The cold-pressed PCC based on PVDF will act as better polymer dielectric for electrical energy storage applications as compared to the reported cold-pressed PMC and the cold pressing may be an effective method of preparation (since the unnecessary introduction of thermal disorder is avoided in this method) in developing polymer dielectrics.

Similar content being viewed by others

1 Introduction

Polymer dielectrics (PD) with higher energy density and lower loss tangent (tan δ) with higher breakdown field strength are the emerging materials of future for electrostatic energy storage applications due to their flexibility, non-toxicity, bio-compatibility, low cost, higher visco-elastic properties, etc. [1,2,3,4,5,6,7,8,9,10,11,12]. For this application, the maximum stored energy density is an important parameter, and for a linear dielectric, the maximum stored energy per unit volume is \(U = \frac{1}{2}K\varepsilon_{0} E_{\hbox{max} }^{2}\),where K is the relative dielectric constant and Emax is the maximum electric field, which can be applied to the material (proportional to the breakdown field of the material) [4,5,6,7,8,9,10,11,12]. In development of these PD, over the last two decades of research, the ferroelectric polymers, e.g. polyvinyledene fluoride (PVDF) matrix, have been preferred due to its high static dielectric constant (~ 15) and higher visco-elastic properties and higher insulating nature as compared to other non-polar polymers [1,2,3,4,5,6,7,8,9,10,11,12,13,14,15,16,17,18,19,20,21,22,23,24,25,26,27]. The varieties of fillers, such as micro- and nanoparticles of metal, ceramic, carbon nanotube, carbon black, graphite, graphene, conducting, and polymer, are under continuous use in the development of these PD [1,2,3,4,5,6,7,8,9,10,11,12,13,14,15,16,17,18,19,20,21,22,23,24,25,26,27,28,29,30,31]. However, the development of the polymer/ceramic composites (PCC) has been dormant over the last decade of research, as the effective dielectric constant (εeff) for these composites was found to be very low, i.e. εeff ~ 100, at low frequencies due to the low dielectric constant of the polymers, as well as due to the conventional hot moulding process conditions [27,28,29,30,31]. In the preparation of these PCC, a very high-dielectric-constant ferroelectric ceramic, such as PMN-PT, BaTiO3, and PbTiO3, with particles of size of micron order is used in order to have improvement in the value of εeff with lower tan δ. However, due to the low dielectric constant of the polymers, even with PVDF matrix (whose static dielectric constant ~ 17), much higher value of εeff with lower tan δ could not be achieved. Hence, in order to have large interfacial polarisation, the nanoparticles of the same ferroelectric ceramics also have been used into the PVDF matrix through hot moulding, and partially the approach becomes effective in order to get better PD [27,28,29,30,31].

In the development of these PCC based on PVDF, the traditional mixed technique (solution casting followed by hot moulding) is used, during which the spherulites of PVDF get lost [32], which results in getting the lower value of εeff. Recently, our group has developed the cold pressing technique in preparing the PD based on PVDF, due to which the spherulites [32] of PVDF are retained, and they help in the additional storage of electrical charge due to the created additional interfaces, which results in higher interfacial polarisation, and hence, the higher value of εeff is achieved [5, 13,14,15,16,17].

In developing these PD, among the variety of fillers, except the insulating ceramic fillers, mostly the polymer/metal or conductor composites (PMC) have undergone research, in the last two decades by various research groups [7,8,9,10,11,12,13,14,15,16,17,18,19,20,21,22,23,24,25,26]. The origin of interest in these PMC is that, in these composites a very high value of εeff, is achieved due to the percolative second-order insulator to metal transition (IMT) at the percolation threshold (fc). At fc, the εeff, tan δ, and effective ac conductivity (σeff) undergo sharp increment due to the IMT and fc becomes the point of discontinuity for εeff in the case of PMC [33]. However, the main drawback of these PMC, which inhibits them from their technological applications, is the unwanted higher value of tan δ and σeff.

Hence, in order to overcome the major difficulty of these PD (higher value of tan δ) based on PMC, the interest on the PCC-based PD should be focused with novel method of preparation in order to have lower value of tan δ along with the higher value of εeff. One of the very simple methods in finding the true percolation behaviour of PMC is the preparation of cold-pressed composites by Panda et al. [5, 13,14,15,16,17], in which the spherulites of PVDF are retained and higher εeff is observed due to the additional storage of electrical charge at the interfaces of the spherulites of the composites.

Hence, we do believe that by changing the traditional process condition (hot moulding of the thick films prepared from solution casting) to the cold pressing method, developed by our group, in which the spherulites of PVDF will be retained for the case of PCC (like that of the PMC), definitely higher value of εeff will be achieved [5, 13,14,15,16,17], with lower tan δ due to the high-dielectric-constant insulating ferroelectric ceramics. Hence, in order to develop a PCC with high εeff and lower tan δ, ferroelectric polymer (PVDF) and high-dielectric-constant nano-ceramic (n-BaTiO3) with particle size ~ 100 nm (having large surface area) were selected, and the prepared composites have undergone the microstructural, dielectric, and electrical conductivity measurement for finding their suitability of applications.

2 Experimental details

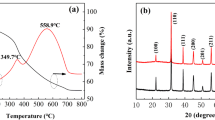

A series of PCC based on PVDF with varying volume fraction of n-BaTiO3 (fBaTiO3) from 0.0 to 0.60 were prepared. The composite powders of PVDF (Alfa Aesar) and the n-BaTiO3 (Aldrich) with particle size < 100 nm were prepared with different fBaTiO3 by mixing with agate mortar/pestle for 2 h, and the final samples were taken in the form of pellets under room temperature consolidation at a pressure of 30 MPa with the help of a hydraulic press. The microstructure investigation on the samples was carried out with the help of FESEM from FEI Company of USA (SE Asia) Pte, Ltd. (Model No. SEM 450). The electrical measurements were made on all the PCC in the frequency range of 50 Hz to 5 MHz and in the temperature range of room temperature to 100 °C with the help of the LCR HiTESTER (Model No. Hioki 3520). The dielectric results of the PCC have been understood with the help of Yamada model fitted with the help of the software Mathematica.

3 Results and discussion

3.1 Microstructure

The FESEM micrographs of the cold-pressed pure PVDF (Fig. 1a, b) and PVDF/n-BaTiO3 composites with different fBaTiO3 up to 0.60 are shown in Fig. 1c–f. Figure 1a, b shows the presence of spherulites (the spherical semi-crystalline regions of the polymer) in the cold-pressed PVDF, while both the spherulites and large created unfilled like structures (due to the cold pressing) are observable from the micrographs (Fig. 1c–f). The diameter of the spherulites present in the polymer is of the order of ~ 0.1 µm (Fig. 1a, b). Interestingly, the n-BaTiO3 taken is of size 100 nm, i.e. 0.1 µm, of the order of diameter of the spherulites. During cold pressing, the n-BaTiO3 clusters may have taken the shape (Fig. 1c–f) inside the polymer matrix, which is of large benefit in the storage of electrical charge. From all the micrographs, it is clear that a various types of interfaces have appeared in the composites and are useful in the storage of electrical charge at the interfaces.

3.2 Dielectric properties

The variation of ɛeff and tan δ of the prepared series of PCC as a function of frequency at 300 K is shown in Fig. 2a, b, respectively. The value of ɛeff at 50 Hz for the 0.0 sample is 16, while this value increases up to 120 linearly up to the PCC with fBaTiO3 = 0.5 and after that it increases up to the value of 330 and 420 for the samples with fBaTiO3 = 0.55 and fBaTiO3 = 0.60, respectively. The higher value of ɛeff for the fBaTiO3 = 0.55 and fBaTiO3 = 0.60 is due to the large interfacial polarisation arising both due to the presence of spherulites and created large interface like structures during cold pressing, while the spherulites are always lost for the hot-moulded samples (Fig. 3).

Variation of a ɛeff and b tan δ as a function of frequency at 300 K for the PD, Inset: tan δ ~ frequency for some typical percolative PMC samples showing higher tan δ [13]

Figure 3 shows the static dielectric constant (εr) of the cold-pressed pure PVDF is ~ 16, i.e. higher than the εr of hot-moulded pure PVDF (~ 10) due to the loss of spherulites (Inset, Fig. 3) of the polymer. The value of ɛeff decreases with increase in frequency for all the PCC due to the absence of contribution from interfacial polarisation at higher frequencies where only the contribution from dipolar and atomic polarisation exists. A very low tan δ for the PCC with fBaTiO3 = 0.6 (having highest ɛeff = 420 observed at 50 Hz) was found to be only 0.9 at 50 Hz and that value also decreases with increase in frequency, and the trend of decrement is also observed for all the PCC. However, in the recently reported cold-pressed PMC [13], the tan δ value was reported to be 10 at 50 Hz (Inset, Fig. 2b) for the percolative sample, with ɛeff ~ 2000. Hence, the PMC at fc shows ten times higher value of tan δ in comparison with the result of PCC, although both types of polymer composites are prepared by the same cold pressing procedure.

The ɛeff, σeff, and tan δ of the composites as a function of fBaTiO3 at different frequencies are shown in Fig. 4. The ɛeff rises linearly from 16 to 120 when fBaTiO3 increases from 0.0 to 0.50 at 100 Hz, while due to the large interfacial polarisation occurring due to the presence of spherulites and interfaces at the PCC, the ɛeff increases largely from 120 to 350 and 420 for fBaTiO3 = 0.55 and 0.60, respectively. It was found that the expression developed by Yamada et al. (which is a model for explaining the sum properties of the composite) can fit the dielectric data very well (Fig. 4b) at frequency 1 kHz or above. The model is given by

where \(\varepsilon_{\text{eff}}\) is the effective dielectric constant of the composite, \(K_{\text{PVDF}}\) and \(K_{{{\text{BaTiO}}_{ 3} }}\) are the dielectric constants of the polymer matrix and the ceramic, respectively, \(f_{{{\text{BaTiO}}_{ 3} }}\) is the volume fraction of the ceramic and ‘n’ is a parameter related to the geometry of ceramic particles [23]. The values of \(K_{\text{PVDF}}\), \(K_{{{\text{BaTiO}}_{ 3} }}\), and n obtained from the fitting of Eq. (1) to the experimentally measured dielectric data of the composites are 17, 1600, and 10, which are in good agreement with the earlier literature [n = 10.6 for PVDF/PZT composites, that found in Ref. 22]. The important point we would like to communicate here is that the Yamada model could not be fitted with the experimental dielectric data of 100 Hz or low frequencies, as the additional contributions of electrical charge (in addition to the presence of sum properties of both the components) at the interface of the spherulites (due to cold pressing) give rise to rapid enhancement of \(\varepsilon_{\text{eff}}\). The analysis suggests that a modified Yamada model may be developed at low frequencies, to account for the contribution of both sum properties and spherulites, which remained as a challenge to take care of the spherulites in this type of cold-pressed PCC. It is important to point out here that, it should be a challenge for theoretical work not only for this investigated case of PCC but also for any other PCC containing spherulites [i.e. containing some additional interfacial polarisation over the conventional sum effect] to be established as a general work.

The σeff and tan δ for all the composites increase with the increase in \(f_{{{\text{BaTiO}}_{ 3} }}\) in the PCC slowly, suggesting the semiconducting nature of the BaTiO3 nano-ceramics, thereby becoming very helpful in the reduction in tan δ with achieved higher \(\varepsilon_{\text{eff}}\)(~ 400). With \(f_{{{\text{BaTiO}}_{ 3} }}\) = 0.6, the σeff value varies within 10−8–10−4 Ω−1cm−1 for frequency varying between 50 Hz and 5 MHz, while the value of tan δ is maintained in between 0.1 and 0.9. The value of σeff and tan δ is also found to be increasing with increase in frequency, suggesting primarily the hopping type of AC conduction in the PCC. Similarly, σeff value for all the PCC was found to be very low, i.e. less than 10−4 Ω−1 for all the PCC and that value also almost remains constant over the entire frequency range. The tan δ increases slowly as a function of fBaTiO3 and was found to be less than 0.9 even with the PCC having fBaTiO3 = 0.6.

The thermal stability of the PCC was checked by measuring the electrical parameters as a function of temperature and is given in Fig. 5. It was found that for fBaTiO3 = 0.4 (Fig. 5a) and fBaTiO3 = 0.50 (Fig. 5b), the low-frequency (50 Hz) value of ɛeff is maintained at a thermal stabilised value of 90 and 130 (with their corresponding decrement as a function of frequency) as a function of temperature from 40 to 100 °C. The stabilisation of ɛeff is attributed to the major effective contribution coming from the sum properties of the dielectric constant of both the components. However, for the samples with fBaTiO3 = 0.55 and 0.6, the reached ɛeff ~ 350 and 420 value arises due to the sum properties of the dielectric constant of both the components and also due to the major contribution of the spherulites. Hence, with the increase in temperature, the ɛeff decreases due to the diminishing of the spherulites of the PCC (Fig. 5c, d). Hence, the spherulites are always useful at room temperature in case of PCC for achieving high value of ɛeff with lower tan δ.

3.3 Electrical conductivity

The variation of ac conductivity (which has been calculated as \(\sigma_{\text{ac}} = \omega \varepsilon_{0} \varepsilon \tan \delta\)) as a function of frequency (conductivity spectrum) at different fBaTiO3 is shown in Fig. 6. The σeff as a function of frequency was found to be the hopping type of conductivity satisfying the Johnscher’s fractional power law of AC conduction [34,35,36]. It can be observed that the plot shows dispersion of ac conductivity with frequency for all the PCC corresponding to fBaTiO3≤ 0.20, agrees very well with Eq. (2), i.e.

with the σdc part becoming zero and the value of k ~ 1. The absence of dc conductivity for the samples with fBaTiO3≤ 0.20 can be interpreted as the non-presence of percolating paths (being formed from the semiconducting BaTiO3 nano-ceramics in the PVDF matrix) due to the insufficient fBaTiO3. It can also be observed that the long-range dc conduction starts to appear for fBaTiO3= 0.3–0.5, but a good fit of Eq. (2) could not be obtained for them as the percolating paths were not sufficient. But interestingly, for the samples with fBaTiO3≥ 0.55, a mixed conductivity is found, i.e. a dc plateau up to a certain frequency, separated by ac conductivity beyond that frequency. The plateau in the conductivity spectrum occurs due to the appearance of long-range dc conductivity. At higher frequency, the conductivity becomes more or less with fBaTiO3 dependent. This frequency at which the change in slope takes place is known as the “hopping or critical frequency ωH,” and it can be observed that ωH increases with increase in fBaTiO3 as it can be observed that the length of dc plateau increases with increase in fBaTiO3 from 0.3 to 0.6 [34,35,36].

However, the value of ‘k’ lies well within the Johnscher’s universal regime [0, 1] suggesting the validity of Johnscher’s power law in all the PCC universally.

4 Conclusions

In conclusion, the microstructural and ac electrical characterisation of a PCC with two component composites, e.g. PVDF/n-BaTiO3 prepared through the effective cold pressing method as a function of frequency and temperature and fBaTiO3, were investigated. It is found that the enhancement of ɛeff of PCC based on PVDF matrix is largely enhanced by the cold pressing process conditions, due to the retention of the spherulites during sample preparation. It is also found that this cold pressing method is more suitable to the PCC based on PVDF matrix (since very low value of tan δ ~ 0.9 is observed) in comparison with PMC based on PVDF matrix in which large value of tan δ ~ 10–100 is observed. The spherulites present in PVDF matrix are always helpful in maintaining the ɛr and in increasing the ɛeff of PCC/PMC. The enhancement of dielectric results has been explained with the help of the both interfacial polarisation at the interfaces of the spherulites and the well-established Yamada model to account for the sum effect observed in these PCC. The development of a theoretical work remained as an open challenge to account for both the contribution of interfacial polarisation and the conventional sum effect presents in this type of PCC. A long-range dc conductivity appears at fBaTiO3≥ 0.55, and the Johnscher’s universal fractional power law is well satisfied for all the PCC. The ac hopping conduction, which is the mechanism in these disordered materials have been confirmed in all PCC. We found that the dynamics of charge carriers are fBaTiO3 and temperature dependent. Again in order to have the applications of PD, the focus of research should be concentrated on still achieving the lower and lower tan δ, which will increase the dielectric field strength as well as the high energy density, suitable for electrical energy storage applications.

In this work, the use of commercial n-BaTiO3 was decided as a component of the PCC, instead of fresh synthesised n-BaTiO3, because the study was mainly focused on the method of preparation, i.e. the cold pressing method in place of the traditional hot moulding process, and the research was not based on fillers, and it was also found that cold pressing is an effective method in the development of PD based on PVDF. However, in future works, the use of sensitised barium titanate as well as functionalised nano-ceramics will be introduced into the polymer matrix, and the effect has to be studied. Again another important point, we would like to mention that since in the cold pressing method, no unnecessary outside thermal disorder is introduced into the PCC, which leads to the development of a better stabilized sample; hence, it acts as an effective method of preparation of the PD having its own advantages.

References

Jawaid M, Khan MM (2018) Polymer-based nanocomposites for energy and environmental applications. Woodhead Publishing, Amsterdam

Lin Z, Yang Y, Zhang A (2017) Polymer-engineered nanostructures for advanced energy applications. Springer, Switzerland

Thakur VK, Kessler MR (2014) Polymer nanocomposites: new advanced dielectric materials for energy storage applications, in advanced energy materials. Wiley, Hoboken

Frohlich H (1958) Theory of dielectrics, Chap. 1. Oxford University Press, London

Panda M (2018) AIP Conf Proc 110:0429051

Panda M, Soni S (2018) Mater Today Proc 110:0429051

Li Q, Chen L, Gadinski MR, Zhang S, Zhang G, Li U, Iagodkine E, Haque A, Chen LQ, Jackson A, Wang Q (2015) Nature 523:576

Li Q, Yao FZ, Liu Y, Zhang G, Wang H, Wang Q (2018) Annu Rev Mater Res 48:3.1

Zhang QM, Li H, Poh M, Xia F, Cheng Z-Y, Xu H, Huang C (2002) Nature 419:284

Chen Q, Shen Y, Zhang S, Zhang QM (2015) Annu Rev Mater Res 45:433

Prateek VK, Thakur RK (2016) Gupta. Chem Rev 116:4260

Dang ZM, Yuan JK, Zha JW, Zhou T, Hu GH (2012) Prog Mater Sci 57:660

Panda M (2017) Appl Phys Lett 110:0429051

Panda M, Srinivas V, Thakur AK (2008) Appl Phys Lett 93:2429081

Panda M, Srinivas V, Thakur AK (2008) Appl Phys Lett 92:1329051

Panda M, Srinivas V, Thakur AK (2011) Appl Phys Lett 99:0429051

Panda M, Srinivas V, Thakur AK (2014) Curr Appl Phys 14:1596

Panda M, Srinivas V, Thakur AK (2014) Mod Phys Lett B 28:1450055

Panda M (2018) J Adv Dielect 08:1850028

Panda M (2010) Scaling and relaxation behaviour of polymer-metal composites across the percolation threshold, Ph.D. Thesis, IIT, Kharagpur

Panda M, Srinivas V, Thakur AK (2014) J Adv Dielectr 04:1450027

Panda M, Srinivas V, Thakur AK (2015) Res Phys 05:136

Zhang L, Bass P, Cheng ZY (2014) Appl Phys Lett 105:042905

Yang M, Zhao H, He D, Bai J (2016) Appl Phys Lett 109:072906

He F, Lau S, Chan HL, Fan J (2008) Adv Mater (Weinheim Ger) 20:A1

Dang ZM, Xu HP, Wang HY (2007) Appl Phys Lett 90:012901

Bai Y, Cheng ZY, Bharati V, Xu HS, Zhang QM (2000) Appl Phys Lett 76:3804

Yamada T, Ueda T, Kitayama T (1982) J Appl Phys 53:4328

Zha JW, Dang ZM, Yang T, Zhou T, Song HT, Li ST, Trans IEEE (2012) Dielectr Electr Insul 19:1312

Fan BH, Zha JW, Wang D, Zhao J, Dang ZM (2012) Appl Phys Lett 100:012903

Chanmal CV, Jog JP (2008) Express Polym Lett 2:294

Criest B, Schultz JM (2016) Prog Polym Sci 56:01

Stauffer D, Aharony A (1992) Introduction to percolation theory. Taylor and Francis, London

Dyre JC, Schroder TB (2000) Rev Mod Phys 72:873

Sinclair DC, West AR (1989) J Appl Phys 66:3850

Sinclair DC, West AR (1994) J Mater Sci 29:6061

Acknowledgements

The Authors would like to thank Prof. V. Verma and Dr. R. K. Pandey for providing the dielectric measurement facility and for fitting the Yamada model with Mathematica, respectively.

Funding

This study was funded by UGC-BSR project [Grant No: F.30-12/2014(BSR)] and DST (SERB) project [Grant No: SR/FTP/PS-177/2011].

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare that they have no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Panda, M., Mishra, A. & Shukla, P. Effective enhancement of dielectric properties in cold-pressed polyvinyledene fluoride/barium titanate nanocomposites. SN Appl. Sci. 1, 230 (2019). https://doi.org/10.1007/s42452-019-0234-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-019-0234-9