Abstract

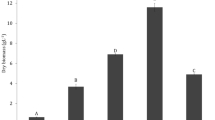

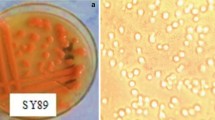

The use of biodiesel has generated a diversification of the energy matrix, which has led to a lower dependence on fossil fuels and a concomitant reduction of the adverse effects on the environment generated by their use. Currently, biodiesel is mainly produced by transesterification with short-chain alcohols of oils from different sources, in particular from oil crops, such as soybean and canola. Since the use of crops for the generation of fuels competes with their use as food, it seems appropriate to explore new oil sources for the production of biodiesel, such as the intracellular triglycerides accumulated by oleaginous yeasts. In this case, to achieve a competitive process, yeast production should be carried out using low-cost fermentable substrates such as industrial wastes or by-products. In this work we optimized the production of intracellular lipids by a previously selected oleaginous yeast strain in a fed-batch culture in presence of crude glycerol as a source of carbon and energy. In the optimized conditions an important improvement of lipid concentration was achieved, obtaining 12.2 g L−1 of fatty acid methyl esters (FAMEs) and 26.6 g L−1 of dry biomass in 360 h of culture.

Similar content being viewed by others

References

Ageitos JM, Vallejo JA, Veiga-Crespo P, Villa TG (2011) Oily yeasts as oleaginous cell factories. Appl Microbiol Biotechnol 90:1219–1227

ASTM D6751-12 (2012) Standard specification for biodiesel fuel blend stock (B100) for middle distillate fuels. ASTM International, West Conshohocken, PA

Azam MM, Waris A, Nahar NM (2005) Prospects and potential of fatty acid methyl esters of some non-traditional seed oils for use as biofuel in India. Biomass Bioenergy 29:293–302. https://doi.org/10.1016/j.biombioe.2005.05.001

EU Directive (2015) 2015/1513 of the European Parliament and of the Council of 9 September 2015, amending directive 98/70/EC relating to the quality of petrol and diesel fuels and amending directive 2009/28/EC on the promotion of the use of energy from renewa. Off J Eur Union L 239:1–29

European Standard N 14214 (2003) Automotive fuels—fatty acid methyl esters (FAME) for diesel engines—requirements and test methods. CEN—European Committee for Standardization, Brussels, Belgium

Galafassi S, Cucchetti D, Pizza F, Franzosi G, Bianchi D, Compagno C (2012) Lipid production for second generation biodiesel by the oleaginous yeast Rhodotorula graminis. Bioresour Technol. https://doi.org/10.1016/j.biortech.2012.02.004

Gui MM, Lee KT, Bhatia S (2008) Feasibility of edible oil vs. non-edible oil vs. waste edible oil as biodiesel feedstock. Energy 33:1646–1653. https://doi.org/10.1016/J.ENERGY.2008.06.002

Kazamia E, Smith AG (2014) Assessing the environmental sustainability of biofuels. Trends Plant Sci 19:615–618

Kraisintu P, Yongmanitchai W, Limtong S (2010) Selection and optimization for lipid production of a newly isolated oleaginous yeast, rhodosporidium toruloides DMKU3-TK16. Kasetsart J Nat Sci 44:436–445

Liang Y, Cui Y, Trushenski J, Blackburn JW (2010a) Converting crude glycerol derived from yellow grease to lipids through yeast fermentation. Bioresour Technol 101:7581–7586. https://doi.org/10.1016/j.biortech.2010.04.061

Liang Y, Sarkany N, Cui Y, Blackburn JW (2010b) Batch stage study of lipid production from crude glycerol derived from yellow grease or animal fats through microalgal fermentation. Bioresour Technol 101:6745–6750. https://doi.org/10.1016/j.biortech.2010.03.087

Martinez-Silveira A, Villarreal R, Garmendia G, Rufo C, Vero S (2018) Process conditions for a rapid in situ transesterification for biodiesel production from oleaginous yeasts. Electron J Biotechnol. https://doi.org/S0717345818300496

Meng X, Yang J, Xu X, Zhang L, Nie Q, Xian M (2009) Biodiesel production from oleaginous microorganisms. Renew Energy 34:1–5

Mosarof MH, Kalam MA, Masjuki HH, Ashraful AM, Rashed MM, Imdadul HK, Monirul IM (2015) Implementation of palm biodiesel based on economic aspects, performance, emission, and wear characteristics. Energy Convers Manag 105:617–629

Pan LX, Yang DF, Shao L, Li W, Chen GG, Liang ZQ (2009) Isolation of the oleaginous yeasts from the soil and studies of their lipid-producing capacities. Food Technol Biotechnol 47:215–220

Papanikolaou S, Aggelis G (2011) Lipids of oleaginous yeasts. Part II: technology and potential applications. Eur J Lipid Sci Technol 113:1052–1073. https://doi.org/10.1002/ejlt.201100015

Patel A, Arora N, Mehtani J, Pruthi V, Pruthi PA (2017) Assessment of fuel properties on the basis of fatty acid profiles of oleaginous yeast for potential biodiesel production. Renew Sustain Energy Rev 77:604–616

Pereyra V, Martinez A, Rufo C, Vero S (2014) Oleaginous yeasts form uruguay and antarctica as renewable raw material for biodiesel production. Am J Biosci 2:251. https://doi.org/10.11648/j.ajbio.20140206.20

Pyle DJ, Garcia RA, Wen Z (2008) Producing docosahexaenoic acid-rich algae from biodiesel derived-crude glycerol: effects of impurities on DHA production and algal biomass composition. J Agric Food Chem 56:3933–3939

Ratledge C (1979) Resources conservation by novel biological processes. Part I: Grow fats from wastes. Chem Soc Rev 8(2):283–296

Saenge C, Cheirsilp B, Suksaroge TT, Bourtoom T (2011) Potential use of oleaginous red yeast Rhodotorula glutinis for the bioconversion of crude glycerol from biodiesel plant to lipids and carotenoids. Process Biochem 46:210–218. https://doi.org/10.1016/j.procbio.2010.08.009

Satpathy P, Thosar A, Rajan AP (2014) Green technology for glycerol waste from biodiesel plant. Int J Curr Microbiol Appl Sci 3:730–739

Sharma YC, Singh B (2009) Development of biodiesel: current scenario. Renew Sustain Energy Rev 13:1646–1651

Sitepu IR, Garay LA, Sestric R, Levin D, Block DE, German JB, Boundy-Mills KL (2014) Oleaginous yeasts for biodiesel: current and future trends in biology and production. Biotechnol Adv 32:1336–1360

Subramaniam R, Dufreche S, Zappi M, Bajpai R (2010) Microbial lipids from renewable resources: production and characterization. J Ind Microbiol Biotechnol 37:1271–1287. https://doi.org/10.1007/s10295-010-0884-5

Tai M, Stephanopoulos G (2013) Engineering the push and pull of lipid biosynthesis in oleaginous yeast Yarrowia lipolytica for biofuel production. Metab Eng 15:1–9. https://doi.org/10.1016/j.ymben.2012.08.007

Thakur MS, Prapulla SG, Karanth NG (1989) Estimation of intracellular lipids by the measurement of absorbance of yeast cells stained with Sudan Black B. Enzyme Microb Technol 11:252–254. https://doi.org/10.1016/0141-0229(89)90101-4

UNIT 1100:2014 (2014) UNIT 1100:2014: Biodiesel (b100). Combustible para uso puro o en mezcla con destilados medios de petróleo-requisitos. Montevideo

Vicente G, Bautista LF, Rodríguez R, Gutiérrez FJ, Sádaba I, Ruiz-Vázquez RM, Torres-Martínez S, Garre V (2009) Biodiesel production from biomass of an oleaginous fungus. Biochem Eng J. https://doi.org/10.1016/j.bej.2009.07.014

Yang F, Hanna MA, Sun R (2012) Value-added uses for crude glycerol—a byproduct of biodiesel production. Biotechnol Biofuels 5:13. https://doi.org/10.1186/1754-6834-5-13

Acknowledgements

This work was supported by Agencia Nacional de Investigación e Innovación (ANII) (Grant no. FSE144810), Comisión Sectorial de Investigación Científica (CSIC Uruguay) and Programa de Desarrollo de las Ciencias Básicas (PDECIBA).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors state that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Martinez-Silveira, A., Pereyra, V., Garmendia, G. et al. Optimization of culture conditions of Rhodotorula graminis S1/2R to obtain saponifiable lipids for the production of second-generation biodiesel. Environmental Sustainability 2, 419–428 (2019). https://doi.org/10.1007/s42398-019-00085-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42398-019-00085-x