Abstract

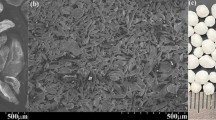

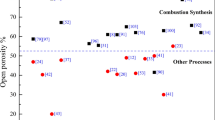

Shaped Mg alloy foams with closed-cell structure are highly interested for a great potential to be utilized in the fields where weight reduction is urgently required. A powder metallurgical method, namely gas release reaction powder metallurgy route to fabricate Mg–X (X=Al, Zn or Cu) alloy foams, was summarized. The principles on shaped Mg–X foams fabrication via the route were proposed. In addition, the effects of alloying elements, sintering treatment and foaming temperatures on fabrication of shaped Mg–X alloy foams were investigated experimentally. The results show that the key to ensure a successful foaming of Mg–X alloy foams is to add alloying metals alloyed with Mg to form lower melting (< 600 °C) intermetallic compounds by the initial sintering treatment. The foaming mechanism of Mg–X alloy foams also has been clarified, that is, the low-melting-point Mg-based intermetallic compounds melt first, and then reactions between the melt and CaCO3, a foaming agent, release CO gas to make the precursor foamed and finally shaped Mg–X alloy foam with a promising cellular structure is prepared. This route has been verified by successful fabrication on shaped Mg–Al, Mg–Zn and Mg–Cu foams with cellular structure.

Similar content being viewed by others

References

L.P. Lefebvre, J. Banhart, D.C. Dunand, Adv. Eng. Mater. 10 (2008) 775–787.

J. Banhart, Prog. Mater. Sci. 46 (2001) 559–632.

L. Huang, H. Wang, D.H. Yang, F. Ye, Z.P. Lu, Intermetallics 28 (2012) 71–76.

D. Schwingel, H.W. Seeliger, C. Vecchionacci, D. Alwes, J. Dittrich, Acta Astronautca 61 (2007) 326–330.

J. Banhart, Int. J. Vehicle Des. 37 (2005) 114–139.

R.A. Shenoi, J.F. Wellicome, Composite materials in maritime structures, Cambridge University Press, Cambridge, UK, 1993.

H.P. Degischer, B. Kriszt, Handbook of cellular metals: production, processing, applications, Wiley-VCH, Bremen, Germany, 2002.

X.T. Lu, Z.G. Zhang, H. Du, H.J. Luo, Y.L. Mu, J.R. Xu, J. Alloy. Compd. 797 (2019) 727–734.

P.F. Li, N.V. Nguyen, H. Hao, Mater. Des. 89 (2016) 636–641.

H. Zhuang, Y. Han, A. Feng, Mater. Sci. Eng. C 28 (2008) 1462–1468.

C.E. Wen, Y. Yamada, K. Shimojima, Y. Chino, H. Hosokawa, M. Mabuchi, Mater. Lett. 58 (2004) 357–360.

Z.G. Xu, J.W. Fu, T.J. Luo, Y.S. Yang, Mater. Des. 34 (2012) 40–44.

D.H. Yang, S.R. Yang, H. Wang, A.B. Ma, J.H. Jiang, J.Q. Chen, D.L. Wang, Mater. Sci. Eng. A 527 (2010) 5405–5409.

C.E. Wen, M. Mabuchi, Y. Yamada, K. Shimojima, Y. Chino, T. Asahina, Scripta Mater. 45 (2001) 1147–1153.

E. Solórzano, M. Hirschmann, M.A. Rodriguez-Perez, C. Körner, J.A. de Saja, Mater. Lett. 62 (2008) 3960–3962.

S.H. Park, Y.S. Um, C.H. Kum, B.Y. Hur, Colloids Surf. A Physicochem. Eng. Aspects 263 (2005) 280–289.

E. Aghion, Y. Perez, Mater. Charact. 96 (2014) 78–83.

G.Q. Lu, H. Hao, F.Y. Wang, X.G. Zhang, Trans. Nonferrous Met. Soc. China 23 (2013) 1832–1837.

D.H. Yang, B.Y. Hur, S.R. Yang, J. Alloy. Compd. 461 (2008) 221–227.

X.C. Xia, W.M. Zhao, Z.H. Wei, Z.G. Wang, Mater. Des. 42 (2012) 32–38.

H. Wang, Y.M. Zhang, B.C. Zhou, D.H. Yang, Y. Wu, X.J. Liu, Z.P. Lu, J. Mater. Sci. Technol. 32 (2016) 509–514.

L.Y. Aguirre-Perales, I.H. Jung, R.A.L. Drew, Acta Mater. 60 (2012) 759–769.

X. Ding, Y. Liu, X. Chen, H.W. Zhang, Y.X. Li, Mater. Lett. 216 (2018) 38–41.

H. Wang, D.F. Zhu, S. Hou, D.H. Yang, T.G. Nieh, Z.P. Lu, Mater. Des. 196 (2020) 109090.

A.R. Kennedy, S. Asavavisitchai, Scripta Mater. 50 (2004) 115–119.

D.H. Yang, J.Q. Chen, H. Wang, J.H. Jiang, A.B. Ma, Z.P. Lu, J. Mater. Sci. Technol. 31 (2015) 361–368.

H. Lin, H.J. Luo, Z.G. Zhang, J.F. Ma, G.C. Yao, Mater. Lett. 188 (2017) 288–290.

F. García-Moreno, J. Banhart, Colloids Surf. A Physicochem. Eng. Aspects 309 (2007) 264–269.

K. Kitazono, Y. Takiguchi, Scripta Mater. 55 (2006) 501–504.

A. Chethan, F. García-Moreno, N. Wanderka, B.S. Murty, J. Banhart, J. Mater. Sci. 46 (2011) 7806–7814.

A. Irretier, J. Banhart, Acta Mater. 53 (2005) 4903–4917.

N. Gupta, D.D. Luong, K. Cho, Metals 2 (2012) 238–252.

T. Miyoshi, M. Itoh, S. Akiyama, A. Kitahara, Adv. Eng. Mater. 2 (2000) 179–183.

D.H. Yang, Z.Y. Hu, W.P. Chen, J. Lu, J.Q. Chen, H. Wang, L. Wang, J.H. Jiang, A.B. Ma, J. Manuf. Process. 22 (2016) 290–296.

D.H. Yang, J.Q. Chen, W.P. Chen, L. Wang, H. Wang, J.H. Jiang, A.B. Ma, J. Mater. Sci. Technol. 33 (2017) 1141–1146.

D.H. Yang, S.S. Guo, J.Q. Chen, J. Lu, L. Wang, J.H. Jiang, A.B. Ma, J. Alloy. Compd. 766 (2018) 851–858.

M. Mukherjee, F. García-Moreno, C. Jiménez, A. Rack, J. Banhart, Acta Mater. 131 (2017) 156–168.

X.C. Xia, J.L. Feng, J. Ding, K.H. Song, X.W. Chen, W.M. Zhao, B. Liao, B.Y. Hur, Mater. Des. 74 (2015) 36–43.

H.M. Helwig, F. García-Moreno, J. Banhart, J. Mater. Sci. 46 (2011) 5227–5236.

A. Erryani, F. Pramuji, D. Annur, M.I. Amal, I. Kartika, IOP Conf. Ser. Mater. Sci. Eng. 202 (2017) 012028.

A.A. Nayeb-Hashemi, J.B. Clark, Phase diagrams of binary magnesium alloys, ASM International, Metals Park, Ohio, USA, 1988.

H. Okamoto, J. Phase Equilib. 15 (1994) 129–130.

H. Okamoto, J. Phase Equilib. 13 (1992) 213–214.

Acknowledgements

This research is supported by National Natural Science Foundation of China (No. 51971017), Science Funds for Creative Research Groups of China (51921001), Program for Changjiang Scholars and Innovative Research Team in University of China (IRT_14R05) and Projects of SKLAMM-USTB (2018Z-19). Dr. H. Wang appreciates the financial support from the Fundamental Research Funds for the Central Universities of China (No. FRF-TP-18-004C1).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Wang, H., Zhu, D.F., Wu, Y. et al. New insight into fabrication of shaped Mg–X alloy foams with cellular structure via a gas release reaction powder metallurgy route. J. Iron Steel Res. Int. 28, 125–132 (2021). https://doi.org/10.1007/s42243-020-00543-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-020-00543-5