Abstract

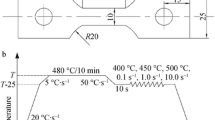

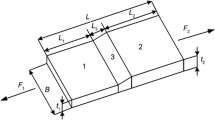

The deformation process of tailor rolled blank (TRB) is different from that of a monolithic blank as a result of the variable thickness in the rolling direction, and thus, the mechanism of the crack phenomenon needs to be further studied. The crack defect of TRB square box was studied by numerical simulation and stamping experiment. The stress state of TRB square box was elaborated. On this basis, the forming characteristics of TRB square box were summarized. The effects of blank size and blank holder force (BHF) on the thickness thinning of TRB were discussed. Finally, the mechanism of the crack defect for TRB square box was revealed. Results indicate that non-uniformity is the most prominent characteristic during forming of TRB square box. The larger the blank size and BHF on the thinner side are, the more inclined TRB is to crack. Excessive BHF or insufficient BHF on the thicker side can also lead to the occurrence of the crack defect. BHF on the thinner side slightly greater than that on the thicker side (40 kN on the thinner side and 20 kN on the thicker side) is advantageous to restrict the excessive thickness thinning of TRB and acquire a better formability. The location inclined to crack for TRB square box is the round corner of the wall on the thinner side.

Similar content being viewed by others

References

R. Krux, W. Homberg, M. Kleiner, Steel Res. Int. 76 (2005) 890–896.

N. Ryabkov, F. Jackel, K. van Putten, G. Hirt, Int. J. Mater. Form. 1 (2008) No. S1, 391–394.

G. Hirt, D.H. Dávalos-Julca, Steel Res. Int. 83 (2012) 100–105.

M. Merklein, M. Johannes, M. Lechner, A. Kuppert, J. Mater. Process. Technol. 214 (2014) 151–164.

R. Kopp, C. Wiedner, A. Meyar, Int. Sheet Met. Rev. 4 (2005) 20–24.

X.H. Liu, J. Iron Steel Res. Int. 18 (2011) No. 1, 1–7.

X.H. Liu, Q.L. Zhao, L.Z. Liu, Acta Metall. Sin. (Engl. Lett.) 27 (2014) 483–493.

P. Groche, M. Mirtsch, Steel Res. Int. 83 (2012) 106–114.

L.J. Chen, B. Han, Y. Yang, Q.W. Huang, X.L. Gan, Steel Rolling 30 (2013) No. 5, 39–43.

M. Urban, M. Krahn, G. Hirt, R. Kopp, J. Mater. Process. Technol. 177 (2006) 360–363.

D. Kim, J. Kim, Y. Lee, H. Kwak, Y. Ryu, B. Han, Rare Metals 25 (2006) No. S2, 111–117.

A. Meyer, B. Wietbrock, G. Hirt, Int. J. Mach. Tools Manuf. 48 (2008) 522–531.

H.W. Zhang, L.Z. Liu, P. Hu, X.H. Liu, J. Iron Steel Res. Int. 19 (2012) No. 9, 8–12.

Y.Q. Wang, J. Li, Y.X. Chen, Automobile Technology & Material (2013) No. 6, 10–13.

H.W. Zhang, X.H. Liu, L.Z. Liu, P. Hu, J.L. Wu, Acta Metall. Sin. (Engl. Lett.) 28 (2015) 1198–1204.

X.J. Bao, Experimental investigation and numerical simulation of springback in tailor rolled blanks bending, Shanghai Jiaotong University, Shanghai, 2003.

H. Zhao, Study on the influencing factors in stamping forming of polyline weld tailor-welded blanks, Harbin Institute of Technology, Harbin, 2010.

H.W. Zhang, X.H. Liu, L.Z. Liu, P. Hu, J.L. Wu, J. Iron Steel Res. Int. 23 (2016) 185–189.

L.H. Lang, D.C. Kang, S.H. Zhang, Z.R. Wang, S.J. Yuan, K.B. Nielsen, J. Dancket, Acta Metall. Sin. (Engl. Lett.) 13 (2000) 476–480.

X.D. Ma, Y.P. Guan, Trans. Nonferrous Met. Soc. China 26 (2016) 228–236.

Y.F. Jiang, X.L. Ding, Y.Y. Zhu, G.D. Yuan, F. Wang, China Mech. Eng. 19 (2008) 2118–2121.

X.D. Ma, Y.P. Guan, L. Yang, Chin. J. Mech. Eng. 28 (2015) 911–918.

T. Wen, P.J. Jia, G. Fang, P. Liu, Hot Working Technology 39 (2010) No. 23, 107–109.

Acknowledgements

This work was funded by National Natural Science Foundation of China (51475086), Natural Science Foundation of Hebei Province (E2016501118), Fundamental Research Funds for the Central Universities (N172304036) and Science and Technology Research Project for Higher School of Hebei Province (ZD2017315).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, Hw., Wu, Jl. & Wang, Xg. Crack defect of tailor rolled blank in deep drawing process. J. Iron Steel Res. Int. 25, 1237–1243 (2018). https://doi.org/10.1007/s42243-018-0184-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-018-0184-2