Abstract

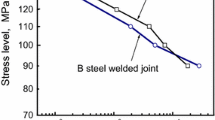

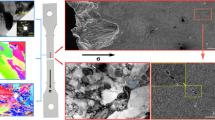

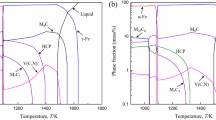

As the increasing need of the steels with both high strength and hydrogen embrittlement resistance ability, carbide precipitation and element distribution in high Co–Ni secondary hardening steel were concerned. Carbide precipitation and element distribution in M54 were observed using carbon replicas method. Both simulation and observation results showed that MC and M2C formed in the steel. MC was round particle, which would act as grain refiners. And M2C was needle-like phase, which would be remarkable strengthening phases. Nb and V were main metallic elements in MC phase. Mo and Cr were main metallic elements in M2C phase. W, Co, and Ni were probably mainly dissolved in the matrix. As the carbide precipitation in AerMet100 was M2C, which had similar size and shape with M2C in M54, the tensile strength and yield strength of AerMet100 and M54 were similar. Compared with traditional high Co–Ni secondary hardening steel, M54 had higher hydrogen embrittlement resistance ability, probably because of element W in the matrix.

Similar content being viewed by others

References

C.C. Wang, C. Zhang, Z.G. Yang, J. Iron Steel Res. Int. 24 (2017) 177–183.

C.C. Wang, C. Zhang, Z.G. Yang, Micron 67 (2014) 112–116.

P. Tao, C. Zhang, Z.G. Yang, T. Hiroyuki, J. Iron Steel Res. Int. 17 (2010) No. 5, 74–78.

R. Ayer, P.M. Machmeier, Metall. Trans. A 24 (1993) 1943–1955.

H.X. Chi, D.S. Ma, H.X. Xu, W.L. Zhu, J.Q. Jiang, J. Iron Steel Res. Int. 23 (2016) 484–488.

Z.F. Hu, X.F. Wu, X.Q. Li, C.X. Wang, X. Fang, J. Iron Steel Res. Int. 8 (2001) No. 2, 56–58.

Z.F. Hu, X.F. Wu, Micron 34 (2003) 19–23.

R. Ayer, P. Machmeier, Metall. Mater. Trans. A 29 (1998) 903–905.

Z.F. Hu, X.F. Wu, X. Li, C. Wang, J. Mater. Eng. Perform. 10 (2001) 493–495.

X. Wang, M. Yan, Q. Meng, Rare Metals 26 (2007) 326–330.

Z. Wang, X. Sun, Z. Yang, Q. Yong, C. Zhang, Z. Li, Y. Weng, Mater. Sci. Eng. A 573 (2013) 84–91.

Z.X. Xia, C.Y. Wang, C. Lei, Y.T. Lai, Y.F. Zhao, L. Zhang, J. Iron Steel Res. Int. 23 (2016) 685–691.

H. Wu, L. Du, Z. Ai, X. Liu, J. Mater. Sci. Technol. 29 (2013) 1197–1203.

K. Miyata, T. Omura, T. Kushida, Y. Komizo, Metall. Mater. Trans. A 34 (2003) 1565–1573.

F. Vodopivec, D. Steiner-Petrovič, B. Žužek, M. Jenko, Steel Res. Int. 84 (2013) 1110–1114.

M.M. Serna, J.L. Rossi, Mater. Lett. 63 (2009) 691–693.

Z.X. Xia, C. Zhang, H. Lan, Z.Q. Liu, Z.G. Yang, Mater. Lett. 65 (2011) 937–939.

F. Shi, Y. Qi, C. Liu, J. Mater. Sci. Technol. 27 (2011) 1125–1130.

D. Figueroa, M.J. Robinson, Corros. Sci. 52 (2010) 1593–1602.

D. Figueroa, M.J. Robinson, Corros. Sci. 50 (2008) 1066–1079.

G.B. Olson, Acta Mater. 61 (2013) 771–781.

G.B. Olson, Ferrium®M54®Overview, 2013, http://www.questek.com/ferrium-m54.html

L.D. Wang, L.Z. Jiang, M. Zhu, X. Liu, W.M. Zhou, J. Mater. Sci. Technol. 21 (2005) 710–714.

K.G. Buchanan, M.V. Kral, C.M. Bishop, Metall. Mater. Trans. A 45 (2014) 3373–3385.

Y. Yamamoto, M.P. Brady, Z.P. Lu, C.T. Liu, M. Takeyama, P. Maziasz, Metall. Mater. Trans. A 38 (2007) 2737–2746.

J. Bratberg, J. Agren, K. Frisk, Mater. Sci. Technol. 24 (2008) 695–704.

J. Cao, Q. Yong, Q. Liu, X. Sun, J. Mater. Sci. 42 (2007) 10080–10084.

A. Zargaran, H.S. Kim, J.H. Kwak, N.J. Kim, Scripta Mater. 89 (2014) 37–40.

Acknowledgements

This work was financially supported by National Basic Research Programs of China (No. 2015CB654802). The authors greatly acknowledge the financial support provided by the National Natural Science Foundation of China (Grant No. 51471094) and the assistance of Engineers Li-jing Hao and Yang Meng in Shougang Research Institute of Technology with the preparation of carbon replica samples and TEM observation.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, Cc., Zhang, C., Yang, Zg. et al. Carbide precipitation and element distribution in high Co–Ni secondary hardening steel. J. Iron Steel Res. Int. 25, 340–346 (2018). https://doi.org/10.1007/s42243-018-0041-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-018-0041-3