Abstract

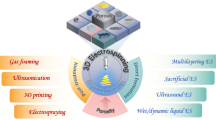

Inspired by the constitution of things in the natural world, three-dimensional (3D) nanofiber scaffold/cells complex was constructed via the combination of electrospinning technology and origami techniques. The nanofiber boxes prepared by origami provided a limited space for the layer-by-layer nanofiber films, and the human fetal osteoblasts (hFOBs) seeded on the both sides of the nanofiber films were expected to facilitate the bonding of the adjacent nanofiber films through the secretion of extracellular matrix. Specifically, the hFOBs presented 3D distribution in the nanofiber scaffold, and they can stretch across the gaps between the adjacent nanofiber films, forming the cell layers and filling the whole 3D nanofiber scaffold. Eventually, a 3D block composed of electrospun nanofiber scaffold and cells was obtained, which possesses potential applications in bone tissue engineering. Interestingly, we also created 3D nanofiber structures that range from simple forms to intricate architectures via origami, indicating that the combination of electrospinning technology and origami techniques is a feasible method for the 3D construction of tissue engineering scaffolds.

Similar content being viewed by others

References

Onozuka K, Ding B, Tsuge Y, Naka T, Yamazaki M, Sugi S, Ohno S, Yoshikawa M, Shiratori S (2006) Electrospinning processed nanofibrous TiO(2) membranes for photovoltaic applications. Nanotechnology 17(4):1026–1031

Jiang S, Liu F, Lerch A, Ionov L, Agarwal S (2015) Unusual and superfast temperature-triggered actuators. Adv Mater 27(33):4865–4870

Liu L, Jiang SH, Sun Y, Agarwal S (2016) Giving direction to motion and surface with ultra-fast speed using oriented hydrogel fibers. Adv Funct Mater 26(7):1021–1027

Formo E, Lee E, Campbell D, Xia Y (2008) Functionalization of electrospun TiO2 nanofibers with Pt nanoparticles and nanowires for catalytic applications. Nano Lett 8(2):668–672

Xu WH, Ding YC, Jiang SH, Zhu J, Ye W, Shen YL, Hou HQ (2014) Mechanical flexible PI/MWCNTs nanocomposites with high dielectric permittivity by electrospinning. Europ Polym J 59:129–135

Xu WH, Ding YC, Jiang SH, Chen LL, Liao XJ, Hou HQ (2014) Polyimide/BaTiO3/MWCNTs three-phase nanocomposites fabricated by electrospinning with enhanced dielectric properties. Mater Lett 135:158–161

Yang CR, Jia ZD, Guan ZC, Wang LM (2009) Polyvinylidene fluoride membrane by novel electrospinning system for separator of Li-ion batteries. J Power Sources 189(1):716–720

Ye W, Zhu J, Liao XJ, Jiang SH, Li YH, Fang H, Hou HQ (2015) Hierarchical three-dimensional micro/nano-architecture of polyaniline nanowires wrapped-on polyimide nanofibers for high performance lithium-ion battery separators. J Power Sources 299:417–424

Sill TJ, von Recum HA (2008) Electrospinning: applications in drug delivery and tissue engineering. Biomaterials 29(13):1989–2006

Sayed E, Karavasili C, Ruparelia K, Haj-Ahmad R, Charalambopoulou G, Steriotis T, Giasafaki D, Cox P, Singh N, Giassafaki LN, Mpenekou A, Markopoulou CK, Vizirianakis IS, Chang MW, Fatouros DG, Ahmad Z (2018) Electrosprayed mesoporous particles for improved aqueous solubility of a poorly water soluble anticancer agent: in vitro and ex vivo evaluation. J Control Release 278:142–155

Wu S, Li JS, Mai J, Chang MW (2018) Three-dimensional electrohydrodynamic printing and spinning of flexible composite structures for oral multidrug forms. ACS Appl Mater Interfaces 10(29):24876–24885

Wang BL, Ahmad Z, Huang J, Li JS, Chang MW (2018) Development of random and ordered composite fiber hybrid technologies for controlled release functions. Chem Eng J 343:379–389

Liu J, Yue Z, Fong H (2009) Continuous nanoscale carbon fibers with superior mechanical strength. Small 5(5):536–542

Huang ZM, Zhang YZ, Kotaki M, Ramakrishna S (2003) A review on polymer nanofibers by electrospinning and their applications in nanocomposites. Compos Sci Technol 63(15):2223–2253

Zhang CC, Gao CC, Chang MW, Ahmad Z, Li JS (2016) Continuous micron-scaled rope engineering using a rotating multi-nozzle electrospinning emitter. Appl Phys Lett 109(15):151903

Seidlits SK, Lee JY, Schmidt CE (2008) Nanostructured scaffolds for neural applications. Nanomedicine (London) 3(2):183–199

Liu X, Wei D, Zhong J, Ma M, Zhou J, Peng X, Ye Y, Sun G, He D (2015) Electrospun nanofibrous P(DLLA-CL) balloons as calcium phosphate cement filled containers for bone repair: in vitro and in vivo studies. ACS Appl Mater Interfaces 7(33):18540–18552

Sun G, Wei D, Liu X, Chen Y, Li M, He D, Zhong J (2013) Novel biodegradable electrospun nanofibrous P(DLLA-CL) balloons for the treatment of vertebral compression fractures. Nanomedicine 9(6):829–838

Duan GG, Jiang SH, Jerome V, Wendorff JH, Fathi A, Uhm J, Altstadt V, Herling M, Breu J, Freitag R, Agarwal S, Greiner A (2015) Ultralight, soft polymer sponges by self-assembly of short electrospun fibers in colloidal dispersions. Adv Funct Mater 25(19):2850–2856

Hsu PC, Wang S, Wu H, Narasimhan VK, Kong D, Ryoung Lee H, Cui Y (2013) Performance enhancement of metal nanowire transparent conducting electrodes by mesoscale metal wires. Nat Commun 4:2522

Wang XF, Ding B, Sun G, Wang MR, Yu JY (2013) Electro-spinning/netting: a strategy for the fabrication of three-dimensional polymer nano-fiber/nets. Prog Mater Sci 58(8):1173–1243

Lee WS, Sunkara V, Han JR, Park YS, Cho YK (2015) Electrospun TiO2 nanofiber integrated lab-on-a-disc for ultrasensitive protein detection from whole blood. Lab Chip 15(2):478–485

Sun B, Long YZ, Zhang HD, Li MM, Duvail JL, Jiang XY, Yin HL (2014) Advances in three-dimensional nanofibrous macrostructures via electrospinning. Prog Polym Sci 39(5):862–890

Jin G, Shin M, Kim SH, Lee H, Jang JH (2015) SpONGE: spontaneous organization of numerous-layer generation by electrospray. Angew Chem Int Ed Engl 54(26):7587–7591

Soliman S, Pagliari S, Rinaldi A, Forte G, Fiaccavento R, Pagliari F, Franzese O, Minieri M, Di Nardo P, Licoccia S, Traversa E (2010) Multiscale three-dimensional scaffolds for soft tissue engineering via multimodal electrospinning. Acta Biomater 6(4):1227–1237

Badrossamay MR, McIlwee HA, Goss JA, Parker KK (2010) Nanofiber assembly by rotary jet-spinning. Nano Lett 10(6):2257–2261

Zhang D, Chang J (2008) Electrospinning of three-dimensional nanofibrous tubes with controllable architectures. Nano Lett 8(10):3283–3287

Wang L, Ahmad Z, Huang J, Li JS, Chang MW (2017) Multi-compartment centrifugal electrospinning based composite fibers. Chem Eng J 330:541–549

Paneva D, Manolova N, Rashkov I, Penchev H, Mihai M, Dragan ES (2010) Self-organization of fibers into yarns during electrospinning of polycation/polyanion polyelectrolyte pairs. Dig J Nanomater Bio 5(4):811–819

Frenot A, Henriksson MW, Walkenström P (2007) Electrospinning of cellulose-based nanofibers. J Appl Polym Sci 103(3):1473–1482

Wang BL, Zhou WY, Chang MW, Ahmad Z, Li JS (2017) Impact of substrate geometry on electrospun fiber deposition and alignment. J Appl Polym Sci 134(19):44823

Zhao S, Zhou Q, Long YZ, Sun GH, Zhang Y (2013) Nanofibrous patterns by direct electrospinning of nanofibers onto topographically structured non-conductive substrates. Nanoscale 5(11):4993–5000

Zhang DM, Chang J (2007) Patterning of electrospun fibers using electroconductive templates. Adv Mater 19(21):3664

Yang H, Dong L (2009) Selective nanofiber deposition using a microfluidic confinement approach. Langmuir 26(3):1539–1543

Ding Z, Salim A, Ziaie B (2009) Selective nanofiber deposition through field-enhanced electrospinning. Langmuir 25(17):9648–9652

Shim IK, Suh WH, Lee SY, Lee SH, Heo SJ, Lee MC, Lee SJ (2009) Chitosan nano-/microfibrous double-layered membrane with rolled-up three-dimensional structures for chondrocyte cultivation. J Biomed Mater Res A 90(2):595–602

Shim IK, Jung MR, Kim KH, Seol YJ, Park YJ, Park WH, Lee SJ (2010) Novel three-dimensional scaffolds of poly(L-lactic acid) microfibers using electrospinning and mechanical expansion: fabrication and bone regeneration. J Biomed Mater Res B Appl Biomater 95(1):150–160

Wang W, Itoh S, Konno K, Kikkawa T, Ichinose S, Sakai K, Ohkuma T, Watabe K (2009) Effects of Schwann cell alignment along the oriented electrospun chitosan nanofibers on nerve regeneration. J Biomed Mater Res A 91(4):994–1005

Hull TC (2005) Origami design secrets: mathematical methods for an ancient art. Math Intell 27(2):92–95

Christian BA (1973) Principles that govern the folding of protein chains. Science 181(4096):223–230

Mahadevan L, Rica S (2005) Self-organized origami. Science 307(5716):1740

Andersen ES, Dong M, Nielsen MM, Jahn K, Subramani R, Mamdouh W, Golas MM, Sander B, Stark H, Oliveira CL (2009) Self-assembly of a nanoscale DNA box with a controllable lid. Nature 459(7243):73–76

Douglas SM, Dietz H, Liedl T, Högberg B, Graf F, Shih WM (2009) Self-assembly of DNA into nanoscale three-dimensional shapes. Nature 459(7245):414

Gracias DH, Kavthekar V, Love JC, Paul KE, Whitesides GM (2002) Fabrication of micrometer-scale, patterned polyhedra by self-assembly. Adv Mater 14(3):235

Leong TG, Randall CL, Benson BR, Bassik N, Stern GM, Gracias DH (2009) Tetherless thermobiochemically actuated microgrippers. Proc Natl Acad Sci USA 106(3):703–708

Bassik N, Stern GM, Jamal M, Gracias DH (2008) Patterning thin film mechanical properties to drive assembly of complex 3D structures. Adv Mater 20(24):4760–4764

Cho J-H, Gracias DH (2009) Self-assembly of lithographically patterned nanoparticles. Nano Lett 9(12):4049–4052

Guo X, Li H, Ahn BY, Duoss EB, Hsia KJ, Lewis JA, Nuzzo RG (2009) Two-and three-dimensional folding of thin film single-crystalline silicon for photovoltaic power applications. Proc Natl Acad Sci USA 106(48):20149–20154

Syms RR, Yeatman EM, Bright VM, Whitesides GM (2003) Surface tension-powered self-assembly of microstructures-the state-of-the-art. J Microelectromech Syst 12(4):387–417

Py C, Reverdy P, Doppler L, Bico J, Roman B, Baroud CN (2007) Capillary origami: spontaneous wrapping of a droplet with an elastic sheet. Phys Rev Lett 98(15):156103

Szczepanowicz K, Dronka-Gora D, Para G, Warszynski P (2010) Encapsulation of liquid cores by layer-by-layer adsorption of polyelectrolytes. J Microencapsul 27(3):198–204

Song J, Gao H, Zhu G, Cao X, Shi X, Wang Y (2015) The preparation and characterization of polycaprolactone/graphene oxide biocomposite nanofiber scaffolds and their application for directing cell behaviors. Carbon 95:1039–1050

Song J, Zhu G, Wang L, An G, Shi X, Wang Y (2017) Assembling of electrospun meshes into three-dimensional porous scaffolds for bone repair. Biofabrication 9(1):015–018

Okamoto M, Dohi Y, Ohgushi H, Shimaoka H, Ikeuchi M, Matsushima A, Yonemasu K, Hosoi H (2006) Influence of the porosity of hydroxyapatite ceramics on in vitro and in vivo bone formation by cultured rat bone marrow stromal cells. J Mater Sci Mater Med 17(4):327–336

Yang C-Y, Lee T-M, Yang C, Chen L, Wu M, Lui T (2007) In vitro and in vivo biological responses of plasma-sprayed hydroxyapatite coatings with posthydrothermal treatment. J Biomed Mater Res A 83(2):263–271

Meng Z, Zheng W, Li L, Zheng Y (2010) Fabrication and characterization of three-dimensional nanofiber membrance of PCL–MWCNTs by electrospinning. Mater Sci Eng C 30(7):1014–1021

Lee K, Kim H, Khil M, Ra Y, Lee D (2003) Characterization of nano-structured poly(ε-caprolactone) nonwoven mats via electrospinning. Polymer 44(4):1287–1294

Nojima S, Hashizume K, Rohadi A, Sasaki S (1997) Crystallization of ε-caprolactone blocks within a crosslinked microdomain structure of poly(ε-caprolactone)-block-polybutadiene. Polymer 38(11):2711–2718

Chen J-P, Chang Y-S (2011) Preparation and characterization of composite nanofibers of polycaprolactone and nanohydroxyapatite for osteogenic differentiation of mesenchymal stem cells. Colloid Surf B 86(1):169–175

Wan C, Chen B (2011) Poly (ε-caprolactone)/graphene oxide biocomposites: mechanical properties and bioactivity. Biomed Mater 6(5):055010

Arraiza AL, Sarasua J, Verdu J, Colin X (2007) Rheological behavior and modeling of thermal degradation of poly (ε-caprolactone) and poly(l-lactide). Int Polym Process 22(5):389–394

Ma H, Su W, Tai Z, Sun D, Yan X, Liu B, Xue Q (2012) Preparation and cytocompatibility of polylactic acid/hydroxyapatite/graphene oxide nanocomposite fibrous membrane. Chin Sci Bull 57(23):3051–3058

Acknowledgements

This study was financially supported by grants from the National Natural Science Foundation of China (51232002, 51502095, 31771027), the Guangdong Natural Science Funds for Distinguished Young Scholar (2016A030306018) and the Guangdong Natural Science Funds (2017B090911008).

Author information

Authors and Affiliations

Corresponding authors

Electronic supplementary material

Below is the link to the electronic supplementary material.

Supplementary material 2 (MOV 15823 kb)

Rights and permissions

About this article

Cite this article

Song, J., Zhu, G., Gao, H. et al. Origami meets electrospinning: a new strategy for 3D nanofiber scaffolds. Bio-des. Manuf. 1, 254–264 (2018). https://doi.org/10.1007/s42242-018-0027-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42242-018-0027-9